A kind of preparation method of color change-resistant wicker lampshade

A technology of lampshade and color change, which is applied in the direction of lampshade, lighting and heating equipment, lighting device parts, etc., can solve the problems of shortening the service life of lampshade, reducing the ornamental value of lampshade, and not being resistant to color change, so as to increase the number and increase Surface energy, anti-yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

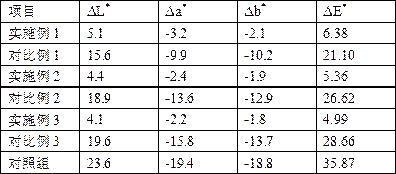

Examples

Embodiment 1

[0017] A method for preparing a color-resistant wicker lampshade, comprising the following steps:

[0018] (1) After cleaning the surface of the woven willow lampshade, put it in an oven and dry it until the water content is 16%;

[0019] (2) Spray the modifying liquid on the surface of the willow lampshade, and then let it dry naturally for 3 days, wherein the modifying liquid is made of the following components by weight: 11 parts of sodium phytate, N-octyl diaminoethyl 7 parts of glycine hydrochloride, 4 parts of sodium formate, 9 parts of formamide, 150 parts of water;

[0020] (3) Put the willow lampshade on a wooden sieve and fumigate with steam, wherein the steam is made by the following method: by weight, put 39 parts of eucalyptus leaves, 20 parts of stinky peony, and 16 parts of grass fruit into 300 parts of water , boil on high heat until boiling, then continue to heat with medium heat, after 30 minutes, add 2 parts of sarcosinate salt, 4 parts of jojoba oil, 5 par...

Embodiment 2

[0026] A method for preparing a color-resistant wicker lampshade, comprising the following steps:

[0027] (1) After cleaning the surface of the woven willow lampshade, put it in an oven and dry it until the water content is 14%;

[0028] (2) Spray the modifying liquid on the surface of the willow lampshade, and then let it dry naturally for 3 days, wherein the modifying liquid is made of the following components by weight: 13 parts of sodium phytate, N-octyl diaminoethyl 8 parts of glycine hydrochloride, 6 parts of sodium formate, 11 parts of formamide, 155 parts of water;

[0029] (3) Place the willow lampshade on a wooden sieve and fumigate with steam, wherein the steam is made by the following method: by weight, put 42 parts of eucalyptus leaves, 23 parts of stinky peony, and 20 parts of grass fruit into 310 parts of water , boil on high heat until boiling, then continue to heat with medium heat, after 35 minutes, add 3 parts of sarcosinate salt, 5 parts of jojoba oil, 7 ...

Embodiment 3

[0035] A method for preparing a color-resistant wicker lampshade, comprising the following steps:

[0036] (1) After cleaning the surface of the woven willow lampshade, put it in an oven and dry it until the water content is 12%;

[0037] (2) Spray the modifying liquid on the surface of the willow lampshade, and then let it dry naturally for 4 days, wherein the modifying liquid is made of the following components by weight: 16 parts of sodium phytate, N-octyl diaminoethyl 10 parts of glycine hydrochloride, 8 parts of sodium formate, 13 parts of formamide, 160 parts of water;

[0038] (3) Place the willow lampshade on a wooden sieve and fumigate with steam, wherein the steam is made by the following method: by weight, put 44 parts of eucalyptus leaves, 25 parts of stinky peony, and 23 parts of grass fruit into 320 parts of water , boil on high heat until boiling, then continue to heat with medium heat, after 40 minutes, add 5 parts of sarcosinate salt, 6 parts of jojoba oil, 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com