Method and device for lubricating the cylinders of a roll stand

一种轧制机架、轧辊的技术,应用在工件润滑装置、轧辊、金属轧制等方向,达到抑制皂化现象的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

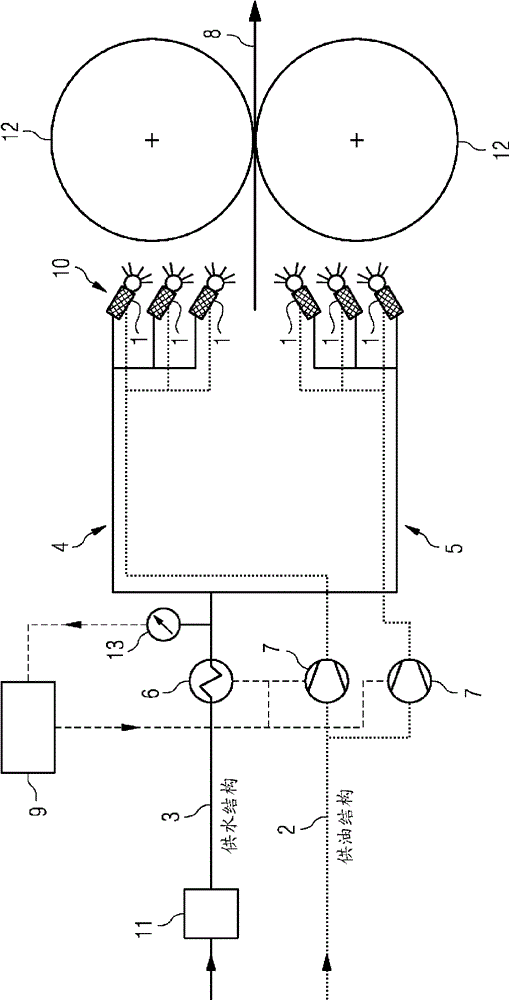

[0018] figure 1 An exemplary embodiment of a device according to the invention for lubricating rolls of a rolling stand is shown schematically. For the sake of clarity, only two work rolls 12 are shown in the rolling stand, in the nip of which the rolling strip 8 is rolled.

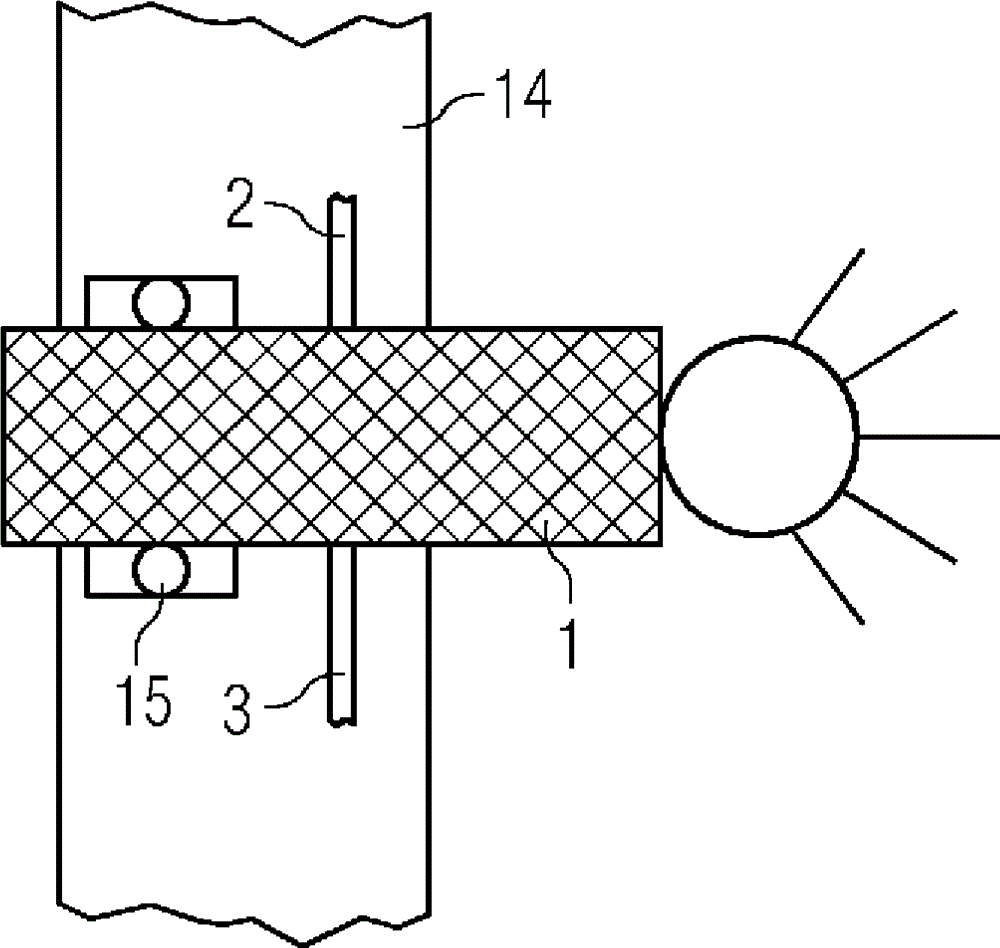

[0019] On the entry side of the work rolls 12, the mixing and spraying mechanism 10 can be seen. This mixing and spraying mechanism 10 consists of a number of nozzle-mixer-units 1 , each of which is supplied with oil and water. Each of these nozzle-mixer-units 1 serves on the one hand as a mixer which processes oil and water into a homogeneous emulsion / suspension. On the other hand, each of these nozzle-mixer units 1 serves as an injection device which introduces the emulsion in the form of a jet into the roll nip. This addition can take place by spraying in the direction of the roll gap or in the direction of the work rolls and / or in the direction of the facing surfaces of the rolled strip. The suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com