Preparation method of fiber reinforced resin

A fiber reinforced resin and resin technology, applied in the direction of coating, can solve the problems of deterioration of surface design and formation of resin-enriched parts, etc., and achieve the effects of curing shrinkage suppression, arrangement disorder suppression, and improvement of surface appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described below with reference to the drawings.

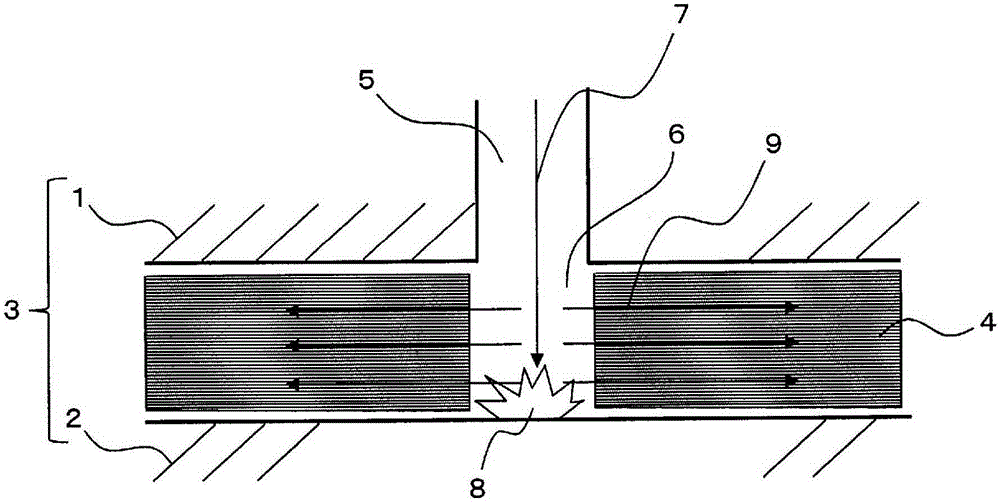

[0030] figure 1 A method for producing a fiber-reinforced resin according to an embodiment of the present invention is shown. In the molding die 3 formed by the upper mold 1 and the lower mold 2, a reinforcing fiber base material 4 formed of, for example, a laminate of a plurality of reinforcing fiber materials is arranged, and the reinforcing fiber base material 4 is opened from a direction facing one surface of the reinforcing fiber base material 4. The injection port 5 of the upper mold 1 is injected with a resin serving as a matrix resin of the fiber-reinforced resin to be molded, and the injected resin is impregnated into the reinforcing fiber base material 4 . A space 6 for passing the injected resin is formed in the reinforcing fiber base material 4 in the molding die 3 by at least partially removing in advance the portion of the reinforcing fiber base material direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com