Low dielectric constant FRP radome and its production process

A glass fiber reinforced plastic radome, low dielectric constant technology, applied in the field of radome, can solve the problem that the mechanical properties do not have stable physical, mechanical, electrical and chemical properties, the effect of glass penetration is not ideal, and the dielectric constant cannot be reduced. , to achieve the effect of good wave permeability, simple structure, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

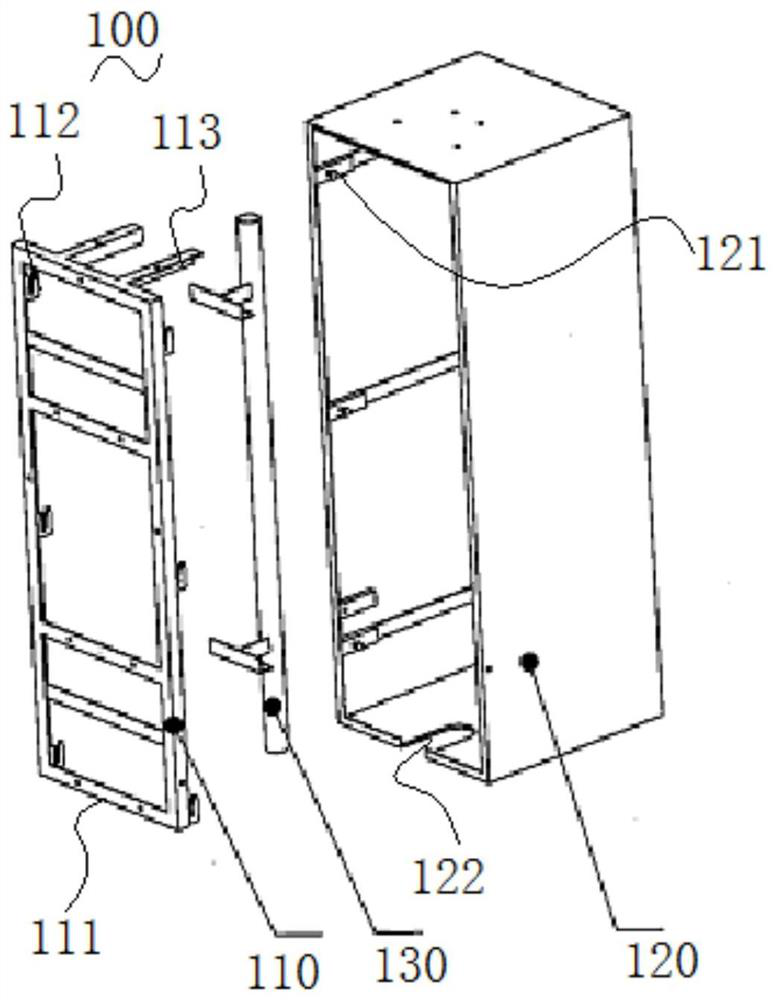

[0025] like figure 1 Shown is the structural representation of the present invention.

[0026] The radome 100 with low dielectric constant and high wave-transparency includes a mounting base 110 for installation on a wall, a protective cover 120 that can be opened and closed outside the mounting base 110, and a protective cover 120 formed by surrounding the mounting base 110 and the protective cover 120. The antenna holding rod 130 in the cavity; the mounting base 110 includes a mounting bottom frame 111, a number of hooks 112 arranged on the side of the mounting bottom frame 111 close to the protective cover 120 for connecting the protective cover 120 and hanging on the mounting bottom frame The support bar 113 on the top of 111 is used to fix the antenna pole 130. The protective cover 120 corresponds to the hook 112 on the mounting seat 110 and is provided with an opening 121 for accommodating the hook 112. The antenna pole 130 corresponds to the support bar 113. There is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com