Acidizing corrosion inhibitor and preparation method thereof

A technology of acidifying corrosion inhibitor and concentrated hydrochloric acid, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of poor compatibility between corrosion inhibitor and acid solution, and the corrosion inhibition performance cannot meet the requirements of use, and achieves good performance. Economic and environmental benefits, reducing construction risks, and good corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

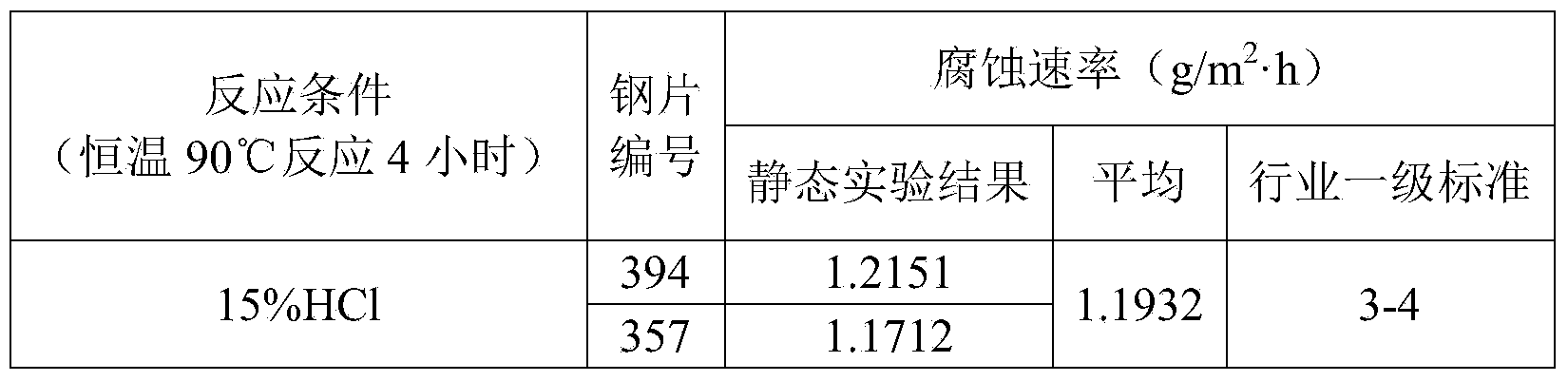

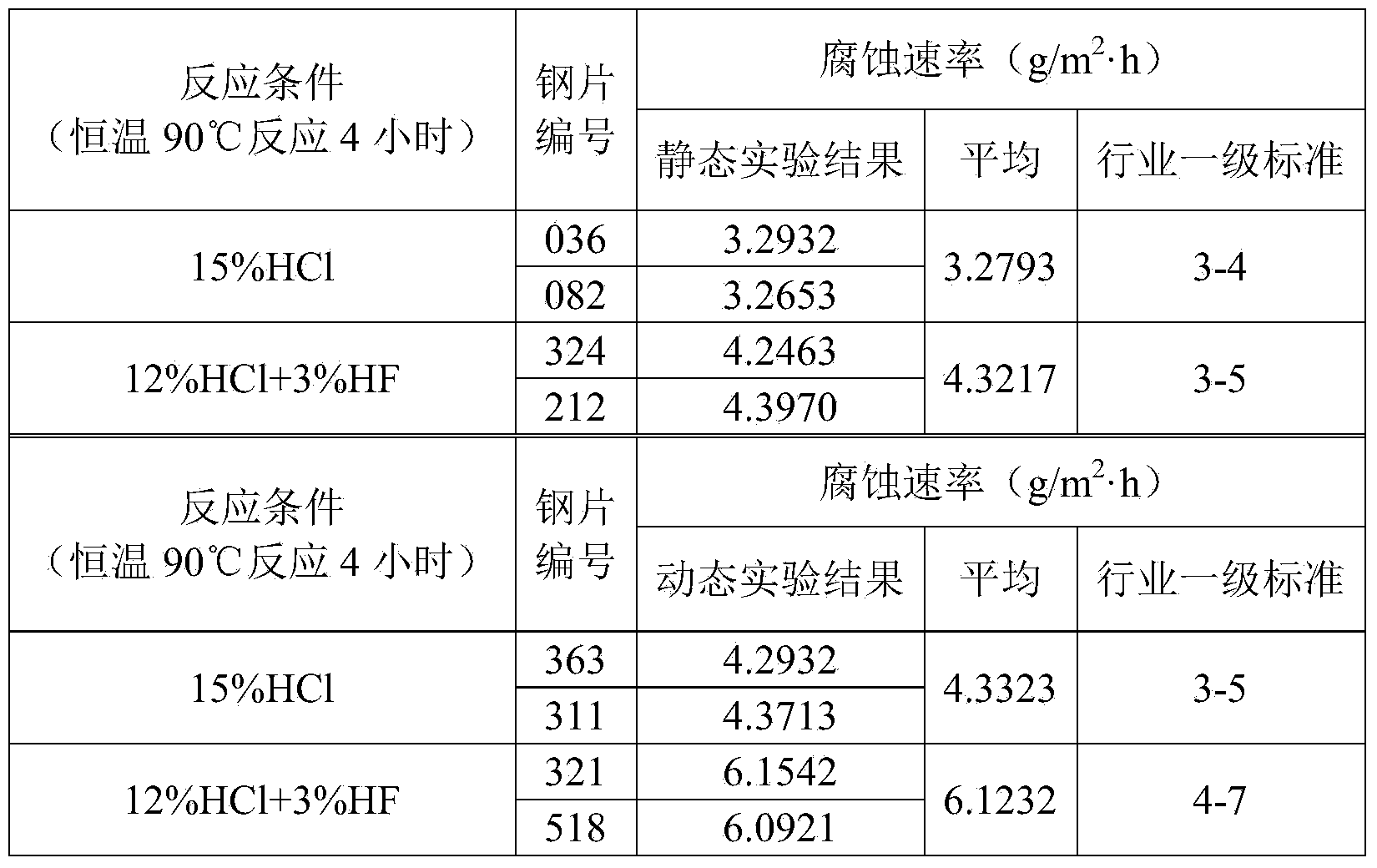

Embodiment 1

[0023] The acidifying corrosion inhibitor of the present embodiment is made from the following raw materials in parts by weight: 40 parts of acetophenone, 24 parts of formaldehyde, 10 parts of ethylenediamine, 24 parts of absolute ethanol, and a mass concentration of 32% concentrated hydrochloric acid 1 2 parts, 2 parts of propargyl alcohol.

[0024] The preparation method of the acidifying corrosion inhibitor of the present embodiment comprises the following steps:

[0025] 1) At room temperature, place acetophenone, formaldehyde, absolute ethanol and concentrated hydrochloric acid in a reaction kettle equipped with an electric stirrer, a return water condenser, and a constant temperature heating device, and stir for 12 minutes to obtain mixture A;

[0026] 2) Add ethylenediamine into the reaction kettle, close the reaction kettle, open the return water condenser and the electric stirrer, raise the temperature of the reaction kettle to 80°C, and react the ethylenediamine with...

Embodiment 2

[0029] The acidifying corrosion inhibitor of the present embodiment is made from the following raw materials in parts by weight: 39 parts of acetophenone, 24 parts of formaldehyde, 9 parts of ethylenediamine, 24 parts of absolute ethanol, and a mass concentration of 36% concentrated hydrochloric acid 1 1 part, propargyl alcohol 1 part.

[0030] The preparation method of the acidifying corrosion inhibitor of the present embodiment comprises the following steps:

[0031] 1) At room temperature, place acetophenone, formaldehyde, absolute ethanol and concentrated hydrochloric acid in a reaction kettle equipped with an electric stirrer, a return water condenser, and a constant temperature heating device, and stir for 10 minutes to obtain a mixture A;

[0032] 2) Add ethylenediamine into the reaction kettle, close the reaction kettle, open the return water condenser and the electric stirrer, raise the temperature of the reaction kettle to 80°C, and react the ethylenediamine with the...

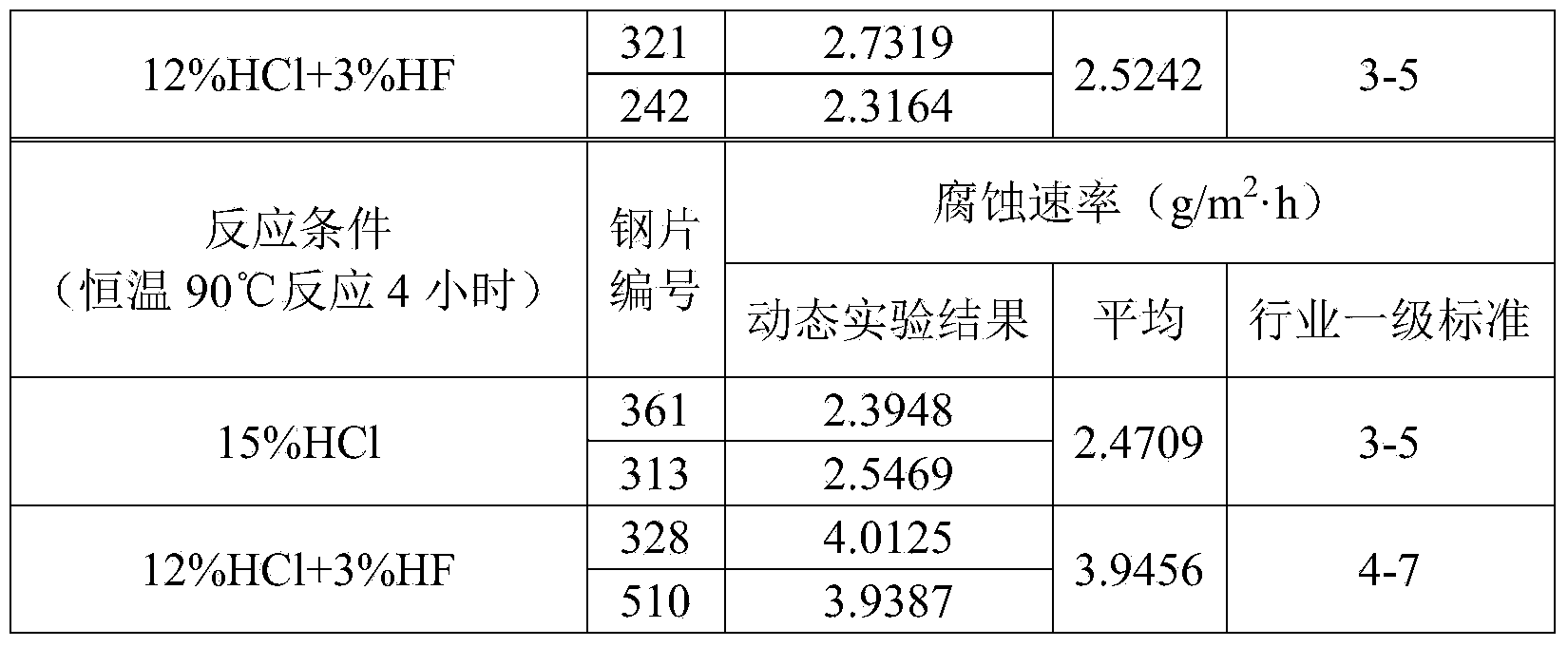

Embodiment 3

[0035] The acidifying corrosion inhibitor of the present embodiment is made from the following raw materials in parts by weight: 41 parts of acetophenone, 26 parts of formaldehyde, 11 parts of ethylenediamine, 26 parts of absolute ethanol, and 2 parts of concentrated hydrochloric acid with a mass concentration of 33%. 1 part, propargyl alcohol 1 part.

[0036] The preparation method of the acidifying corrosion inhibitor of the present embodiment comprises the following steps:

[0037] 1) At room temperature, place acetophenone, formaldehyde, absolute ethanol and concentrated hydrochloric acid in a reaction kettle equipped with an electric stirrer, a return water condenser, and a constant temperature heating device, and stir for 15 minutes to obtain mixture A;

[0038] 2) Add ethylenediamine into the reaction kettle, close the reaction kettle, open the return water condenser and the electric stirrer, raise the temperature of the reaction kettle to 80°C, and react the ethylenedi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap