Intelligent lengthways interconnected feeder line automatic control method

A feeder automation and control method technology, applied in the direction of electrical components, information technology support systems, circuit devices, etc., can solve the problems of power failure of the whole line, affect the reliability and quality of power supply, and long fault isolation time, so as to shorten the power failure time , Convenient feeder fault location, improve the effect of power supply reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

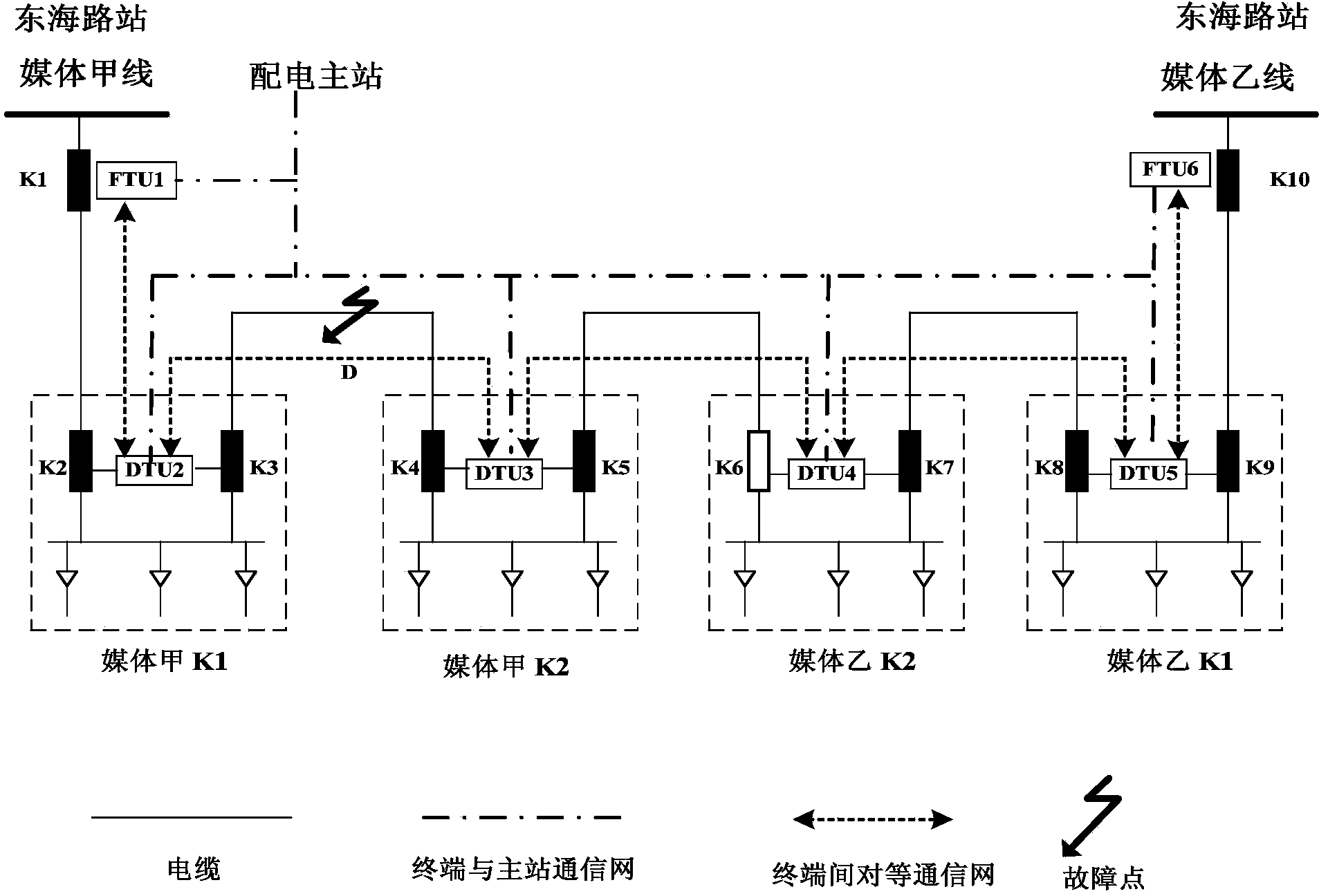

[0042] The method of the present invention is in figure 1 Realized on the intelligent vertically interconnected feeder automation system shown, the intelligent vertically interconnected feeder automation system in this preferred embodiment includes a main distribution station and several distribution substations (distribution substations of line 1: media A K1, media A K2 ; Distribution substation of line 2: media B K2, media B K1), feeder measurement and control terminal FTU1, intelligent distributed power distribution terminals DTU2, DTU3, DTU4, DTU5, feeder measurement and control terminal FTU6, section switch K1, section switch K2 , sectional switch K3, sectional switch K4, sectional switch K5, sectional switch K7, sectional switch K8, sectional switch K9, sectional switch K10 and contact switch K6, the power distribution main station is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com