Equipment for rail handling with controlled tracking of handling tools

A technology of equipment and rails, which is applied in the field of rail processing equipment to achieve the effect of long standard travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

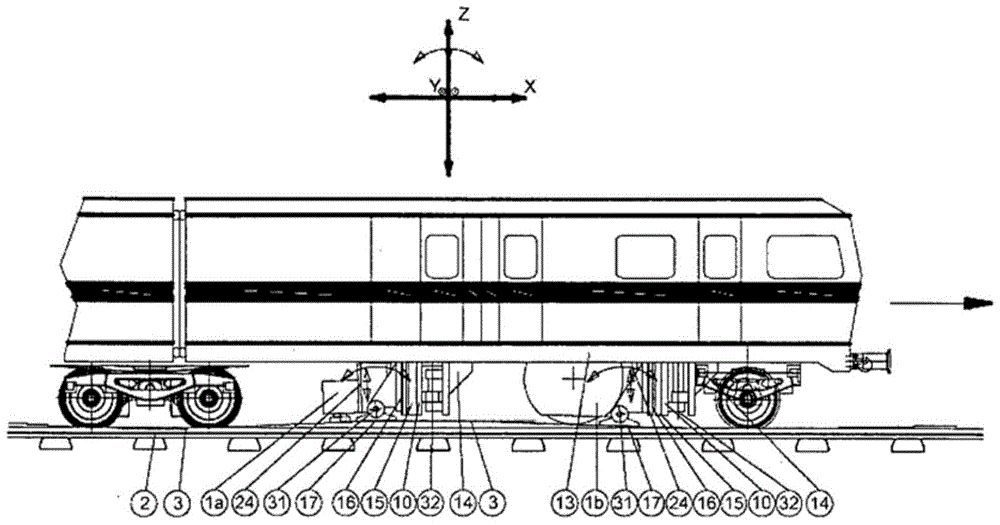

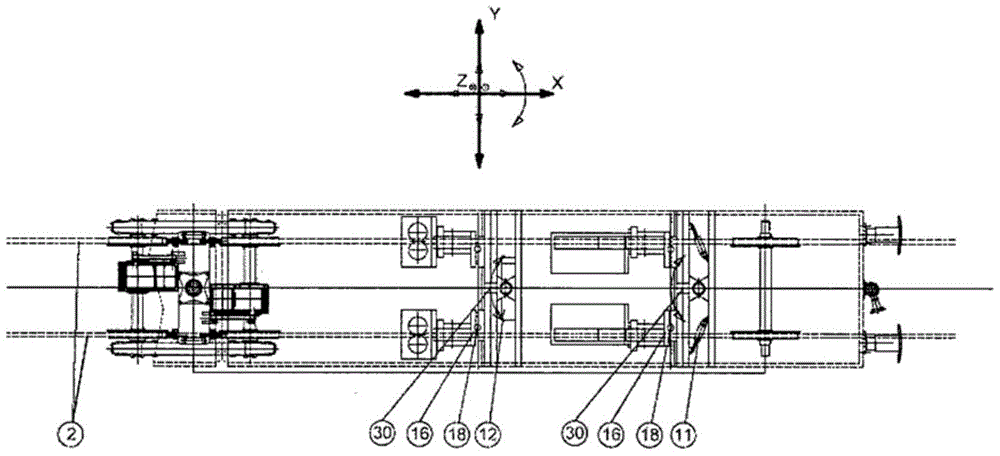

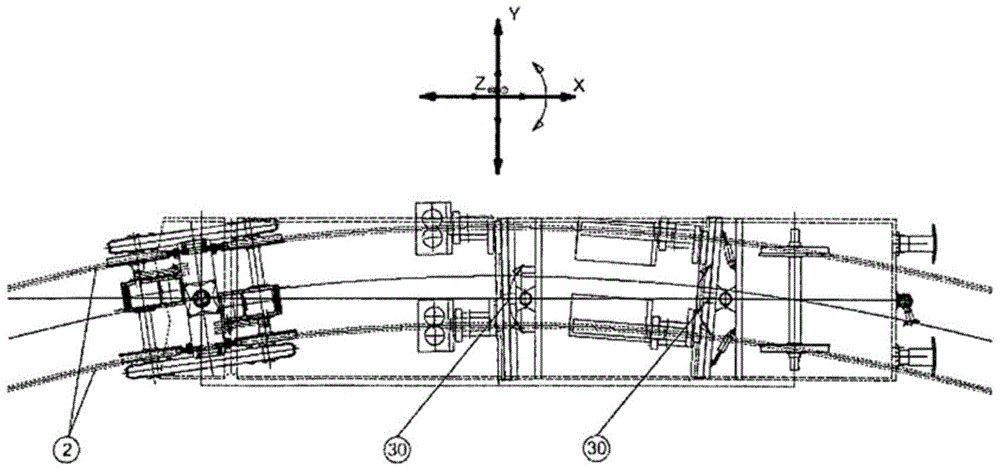

[0086] With the device according to the invention, correspondingly several degrees of freedom can be assigned and used for tracking along the individual rails (2), ie each rail (2) can be tracked independently of the other. There are at least four degrees of freedom, preferably two axes of rotation about the X (30) and Z (32) axes and two linear axes of the Y and Z axes. Furthermore, in a further embodiment variant, a rotation about the Y-axis ( 31 ) and additionally a linear movement along the X-axis can also be controlled by means of the device according to the invention.

[0087] Tracking can be carried out on the one hand according to the principle of an industrial robot, preferably a bent-arm robot, and on the other hand also by another suitable combination of linear movement and rotation.

[0088] It is also possible to combine the movement of the two rails (2) via the fastening plates (10, 15), especially if the common rail quality can be improved in the interaction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com