Metal mask

A metal mask and metal sheet technology, applied in the mask field, can solve the problems of easy warping and affect the coating quality, and achieve the effect of ensuring the quality and improving the problem that the tip is too sharp and easy to warp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

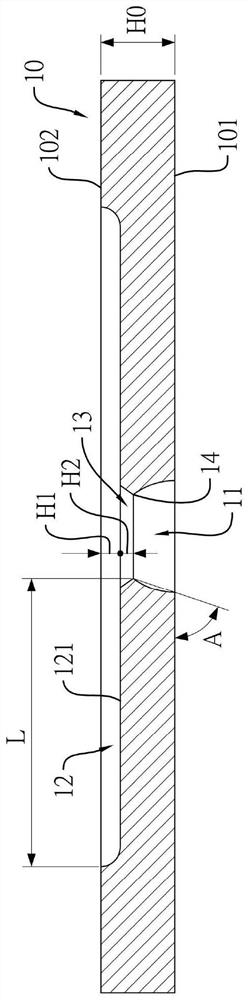

[0038] Such as figure 1 As shown, a preferred embodiment of the metal mask of the present invention is disclosed. As can be seen from the accompanying drawings, the metal mask includes a thin metal plate 10. In this preferred embodiment, the thickness of the metal plate 10 is H0 is about 15 μm to 300 μm, and the material of the metal plate 10 can be a metal plate with a low expansion coefficient such as nickel-iron alloy, but not limited thereto.

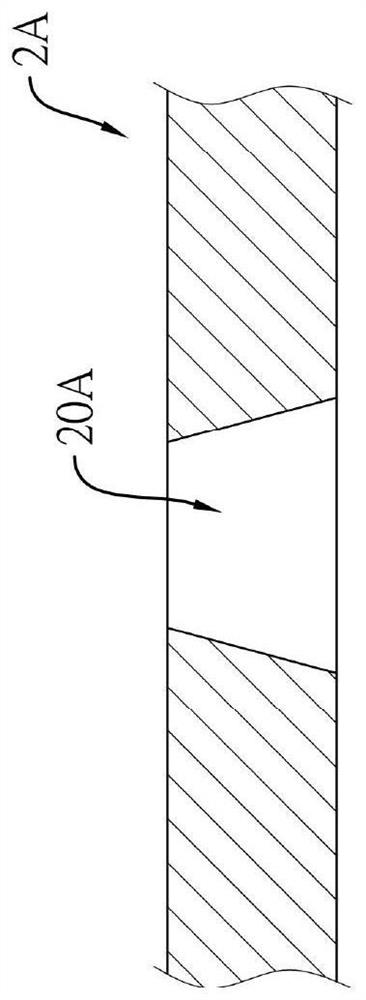

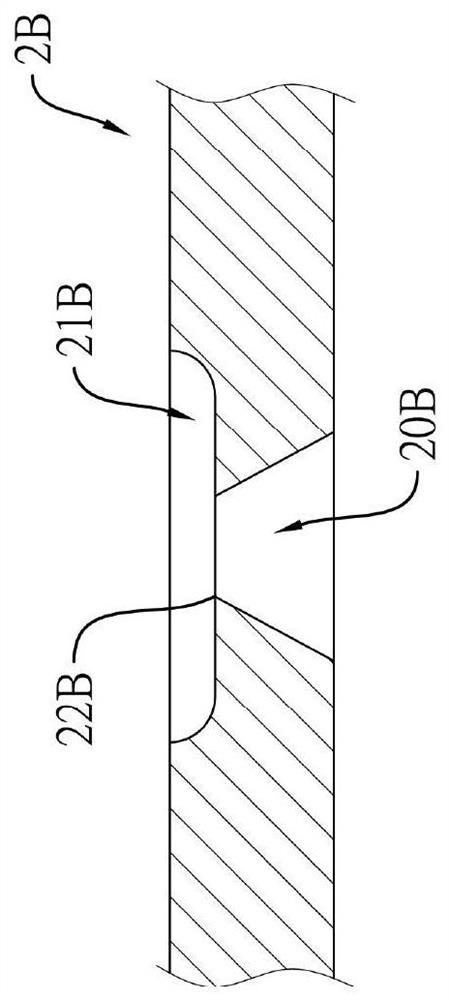

[0039] The opposite sides of the metal plate 10 are respectively the deposition material receiving side 101 and the substrate receiving side 102, and the metal plate 10 includes at least one plated film hole 11, at least one groove 12 and at least one passivation hole 13, when said When there are multiple coating hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com