Fuel injectors for turbomachines

A technology of fuel injector and turbine engine, applied in the fuel valve of turbine/propulsion device, fuel control of turbine/propulsion device, fuel flow passage of turbine/propulsion device, etc., can solve the problem of harmful, uneven performance of turbine engine, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

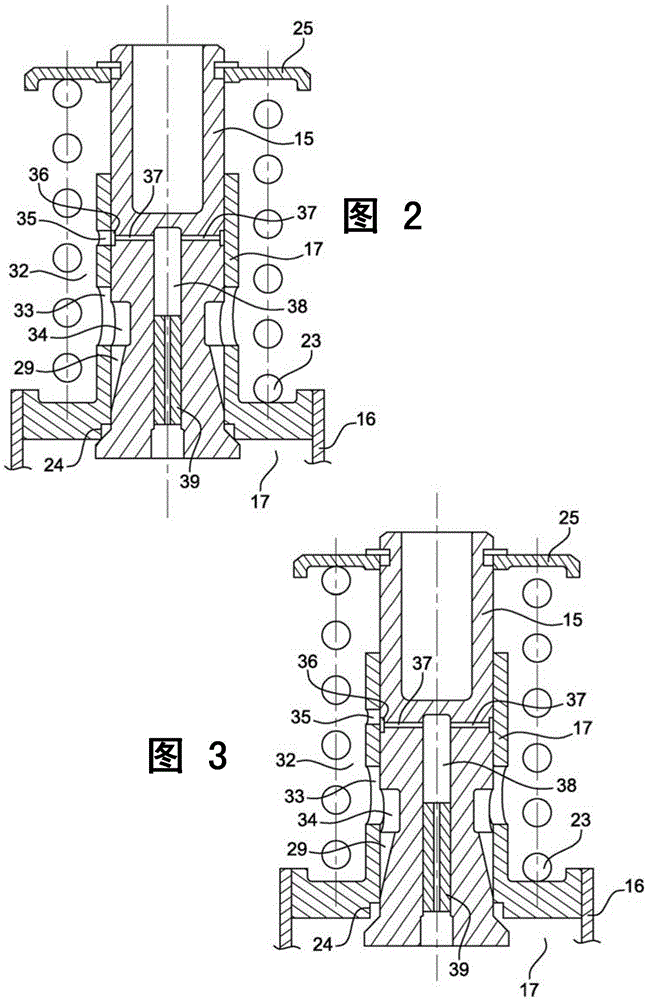

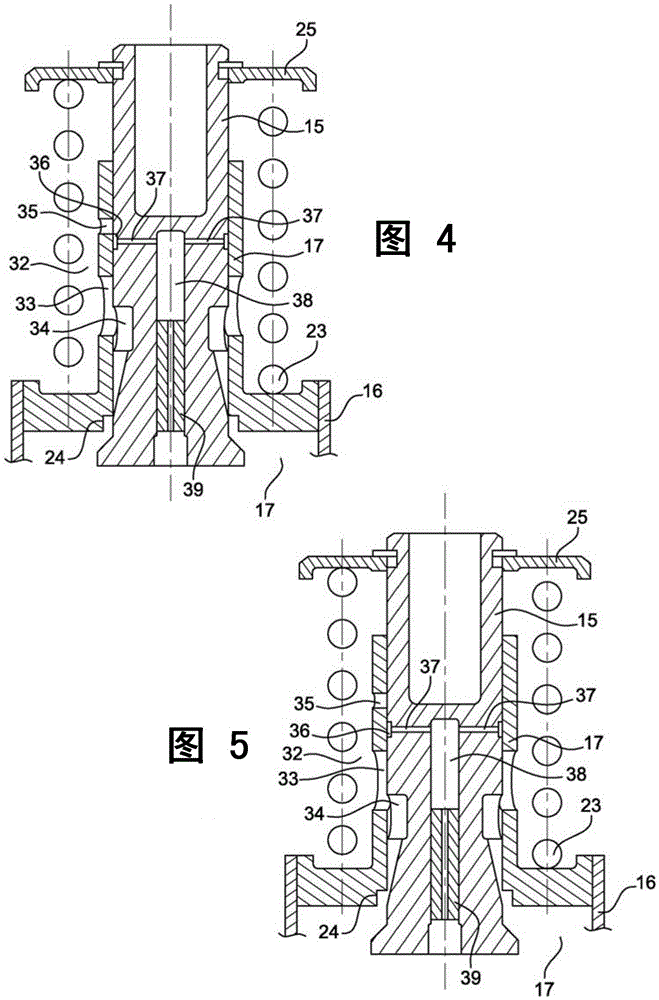

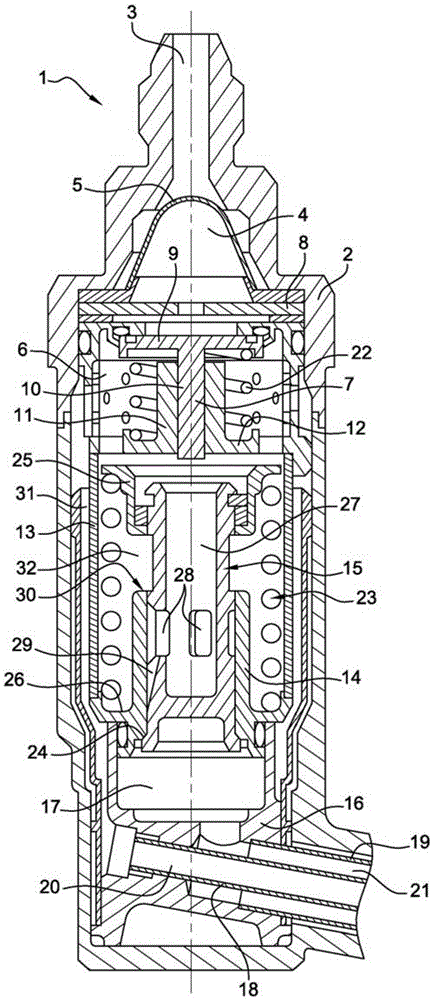

[0027] figure 1 The fuel injector 1 disclosed in the patent application FR2832492 in the applicant's name is shown in .

[0028] This injector 1 is of the aerodynamic type and comprises a primary fuel circuit, for example, for use during start-up and low power phases, and a secondary fuel circuit, which participates in addition to the primary circuit at medium and high power subsequent during the work phase.

[0029] The injector 1 has a hollow body 2 with a fuel inlet 3 for receiving fuel under pressure from a fuel pump (not shown) and opening into a pre-feed chamber 4 after passing through a strainer 5 .

[0030] The body 2 also has a feed chamber 6 downstream of the pre-feed chamber 4 (in the flow direction of the fuel through the injector) and separated therefrom by a shut-off valve 7 . A partition 8 is placed between the pre-feed chamber 4 and the shut-off valve 7 .

[0031] The shut-off valve 7 has a head 9 and a stem 10 mounted movably in a tubular portion 11 of an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com