Tail gas collecting device

A technology of exhaust gas collection and chamber body, which is applied in the direction of smoke removal, cleaning methods and appliances, chemical instruments and methods, etc., which can solve the problems of inconvenient maintenance, poor versatility, and poor exhaust gas collection effect, and achieve good versatility and convenient maintenance , Exhaust gas collection and discharge effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

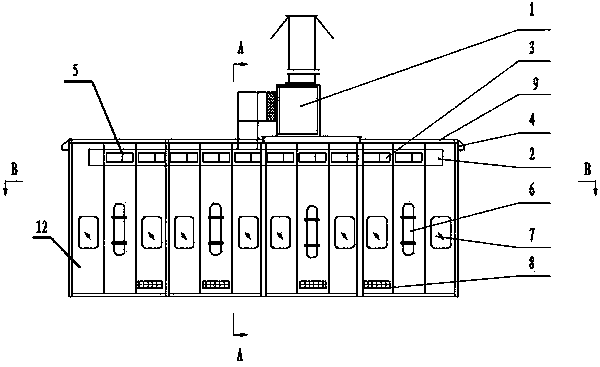

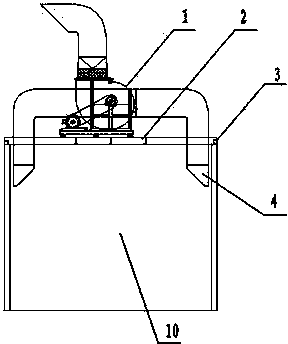

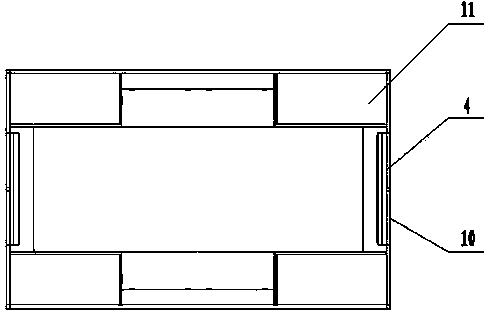

[0012] like figure 1 , figure 2 , image 3 The exhaust gas collection device shown includes a chamber body 9 and a waste exhaust fan assembly. The waste exhaust fan assembly is composed of a centrifugal fan 1 and an air duct 2. The air supply port of the centrifugal fan 1 is softly connected with the air inlet of the air duct 2. Centrifugal fan 1 is located on the top of the roof outside the chamber body 9, and the air duct 2 is located on the top of both sides of the chamber body 9, and the air outlet of the air duct 2 rises out of the roof of the chamber body 9, and the air outlet adopts a 90-degree bend head, which can effectively prevent rainwater from entering; the air duct 2 is provided with a plurality of air outlets 3, and an insert plate 5 is provided on the air outlet 3, and the size of the air outlet 3 can be adjusted through the insert pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com