Automatic loading and unloading line for workpiece machine tool processing

A technology of automatic loading and unloading and automatic unloading, which is applied in metal processing and other directions, can solve the problems of the production impact of the whole line, and achieve the effect of increasing daily output, reducing manpower demand and reducing working hours demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

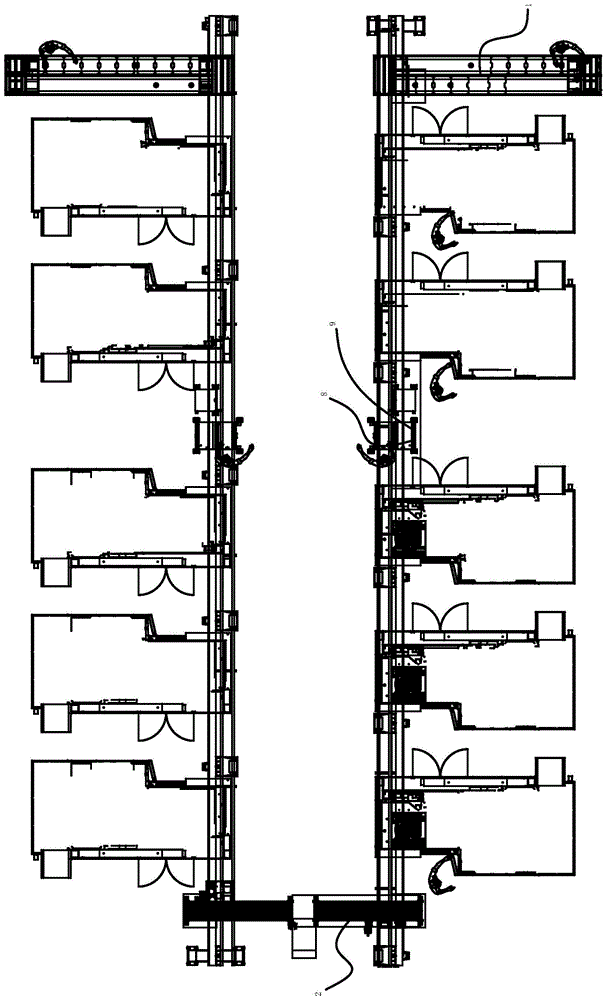

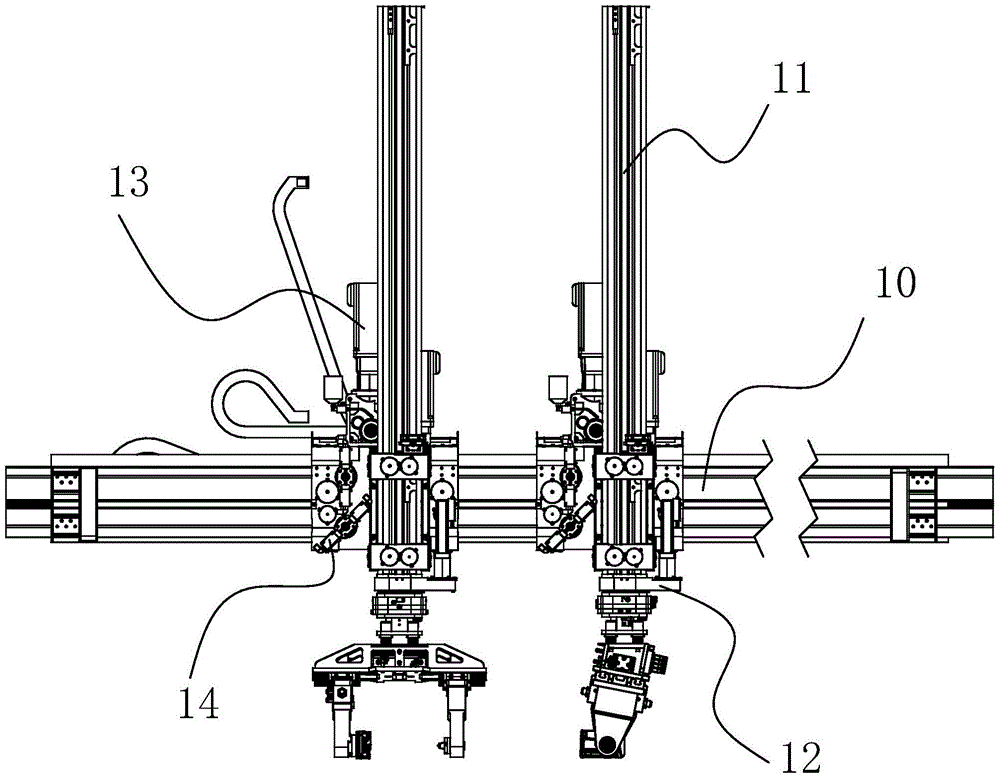

[0028] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the automatic loading and unloading line for workpiece machine tool processing of the present invention includes a first linear four-axis robot, a second linear four-axis robot, two sets of manual loading lines, a feeding conveyor line 1, an automatic blanking conveyor line and an electric control system ( not shown in the figure).

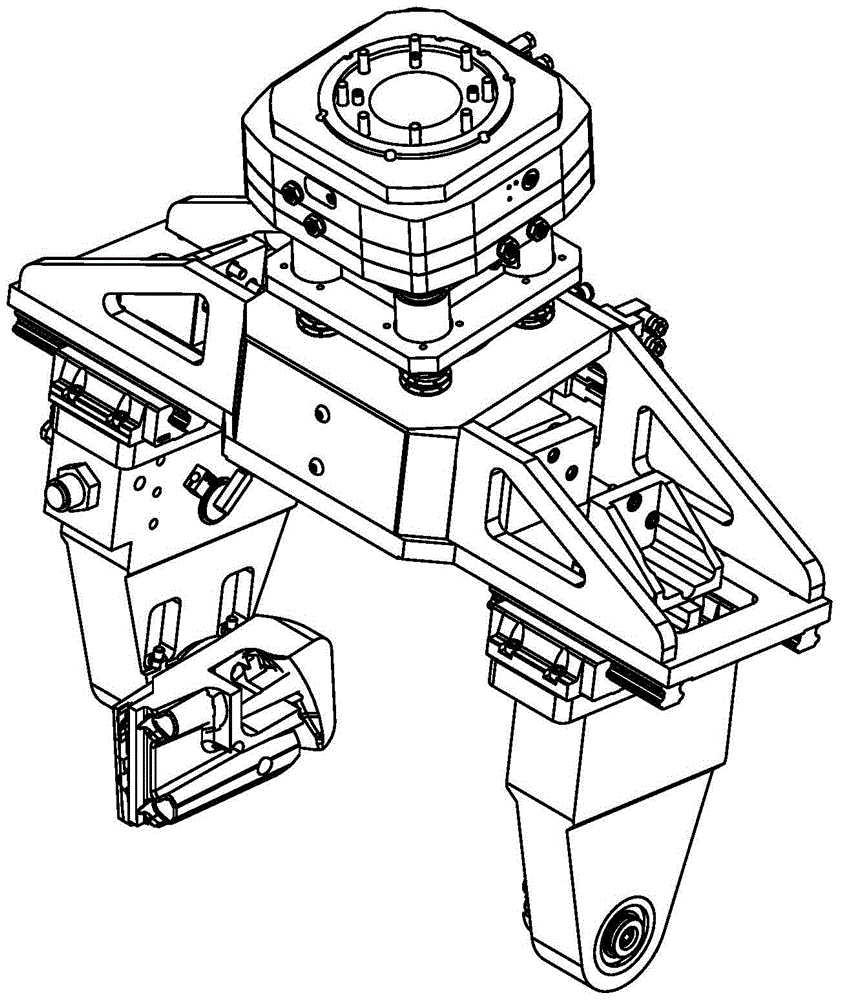

[0029] Both the first linear four-axis robot and the second linear four-axis robot are provided with a first gripper and a second gripper, the first gripper is responsible for workpiece loading, and the second gripper is responsible for workpiece unloading.

[0030] The automatic unloading conveyor line includes two roller conveyor lines and a turning machine that can rotate 90°, and the workpiece sensor is set on the roller conveyor line.

[0031] The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com