A kind of wood-plastic sanding machine

A sanding machine and wood-plastic technology, which is applied in the field of sanding machines, can solve problems such as harsh grinding environment, poor grinding effect, and poor quality of finished products, and achieve the effects of low maintenance rate, high work efficiency, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

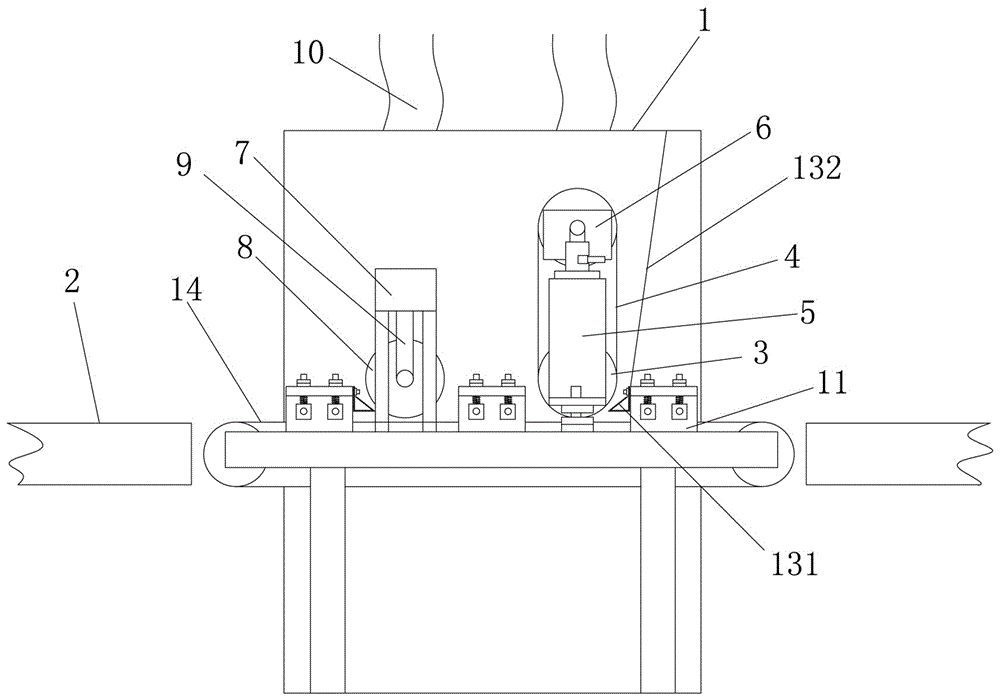

[0036] A wood-plastic sanding machine, comprising a frame, a casing 1 which is arranged on the frame and connected to an exhaust pipe 10 at the top, sanding parts arranged on the frame inside the casing in sequence, and used for removing wood-plastic boards The burr-removing parts polished by the sanding parts on the upper part and the conveyor belt 14 that is arranged on the two ends of the frame and protrudes from the chassis 1 and is located under the sanding parts and the deburring parts. Prismatic anti-skid lines are evenly distributed on the conveyor belt . The hair removal roller not only has the effect of deburring, but also has the effect of removing residual powder.

[0037] The front and rear ends of the corresponding conveyor belt outside the cabinet are provided with storage platforms 2 for shelving wood-plastic boards. 3 and the sanding belt 4 that is sheathed on the transmission roller, the sanding frame includes the lower frame 5 that is arranged in the cabine...

Embodiment 2

[0043] The difference from the above embodiments is that each conveying frame is provided with a conveying roller.

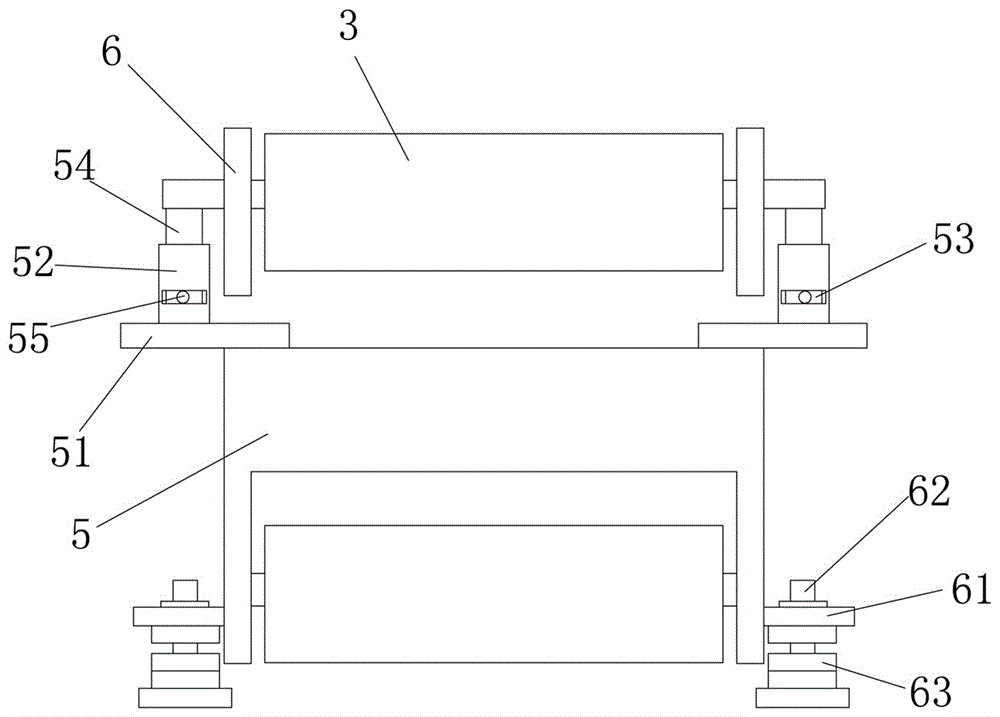

[0044]The connecting kit includes a connecting plate 51 fixed on the top of the lower frame and protruding to the outside of the lower frame, a sleeve 52 arranged on the connecting plate 51 and having a side hole 53, and inserted into the sleeve 52 from top to bottom for It is fixedly connected to the adjusting column 54 on the rack, and the adjusting column is provided with a plurality of horizontally arranged sockets, and the sleeve and the adjusting column are connected by an insertion rod 55 passing through the side hole and inserted into the socket.

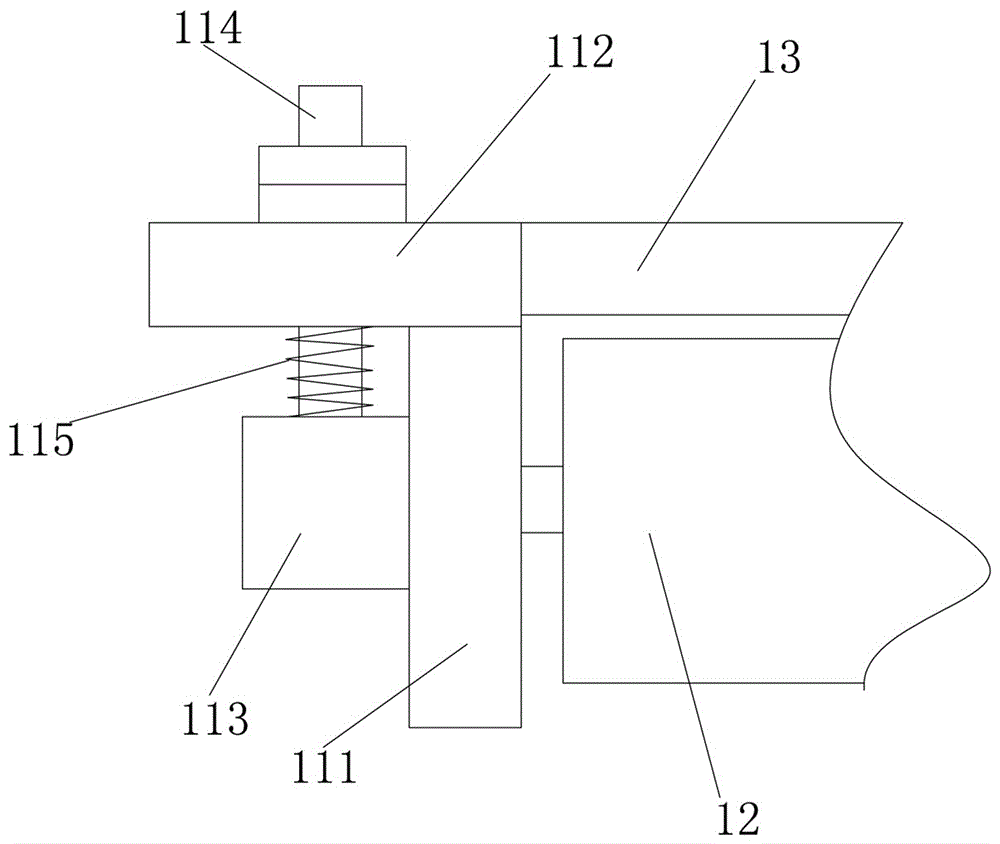

[0045] A chip guide plate 131 is arranged on the cover plate 13 in the conveying roller set inside the front and rear box panels of the cabinet, inclined toward the center of the cabinet. The chip guide plate is a folded plate with a triangular cross section.

[0046] A large guide plate 132 is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com