Easily-tearing packaging bag

A technology for easy-tear packaging bags and bag bodies, applied in the field of packaging bags, can solve problems such as increased cost, increased production process, less safety, etc., and achieves the effects of saving raw materials and costs, increasing internal space, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

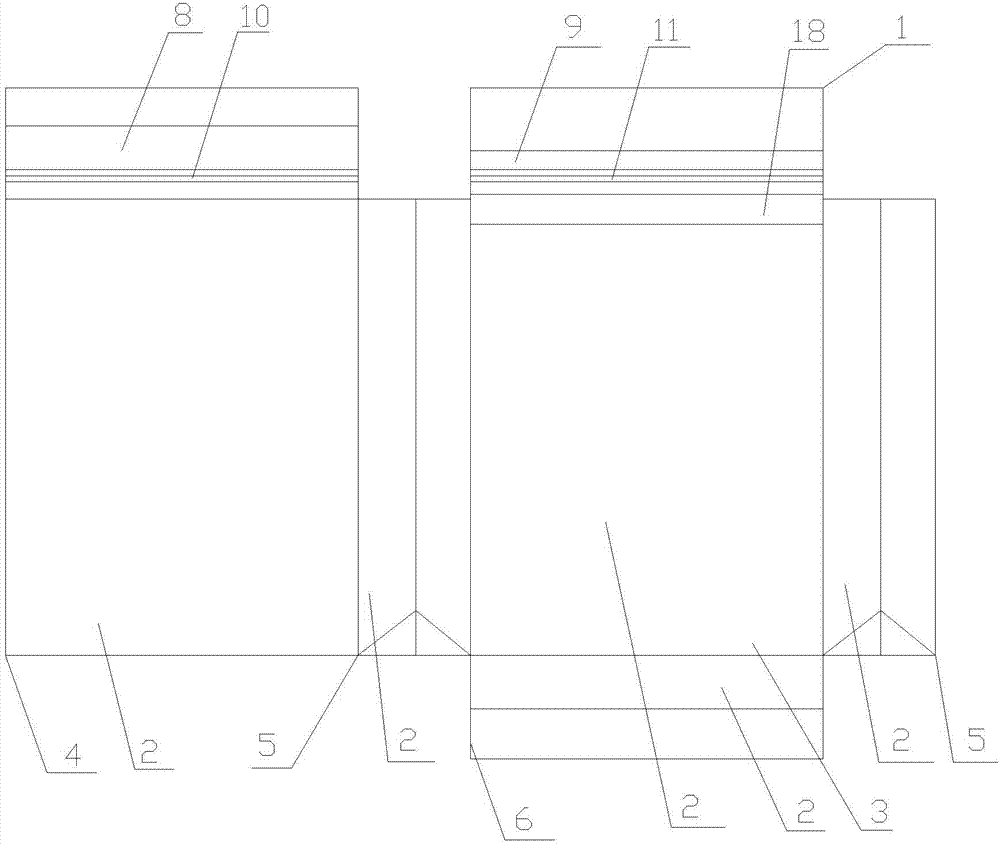

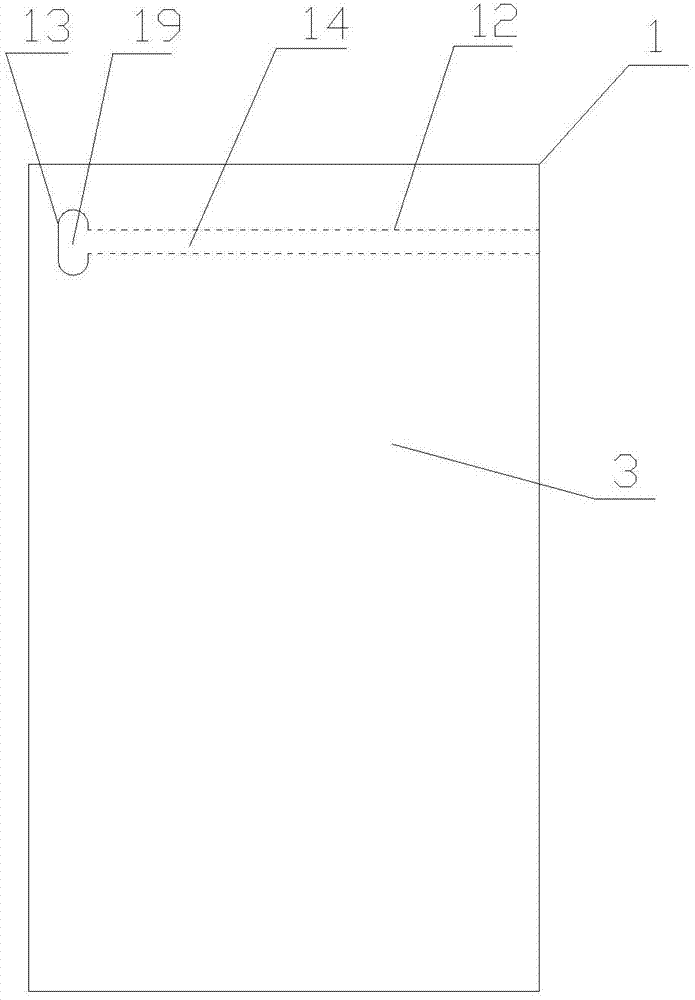

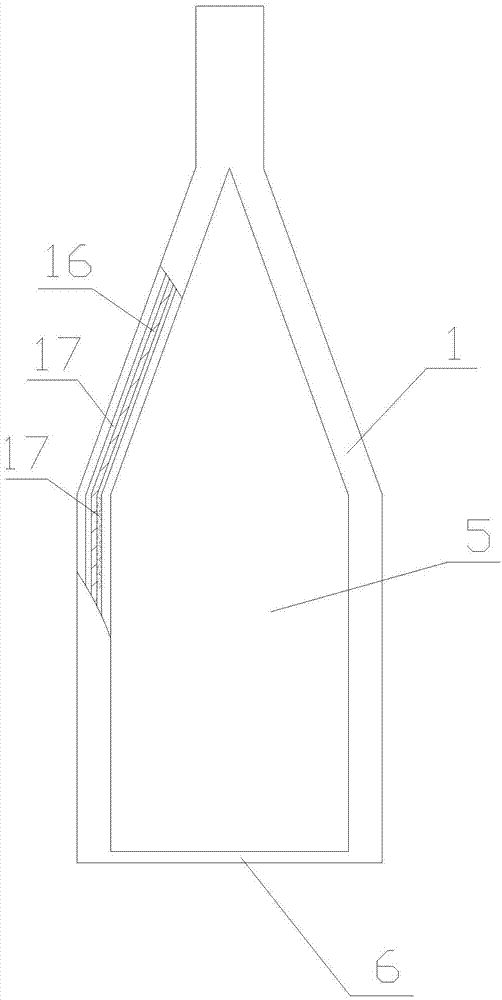

[0026] The present invention provides an easy-tear packaging bag, please refer to figure 1 , including a bag body 1, the inner layer of the bag body 1 is covered with a layer of PE film 2, the bag body is formed by sealing and encapsulating the front side of the bag body 3, the back side of the bag body 4, the sides of the bag body 5 and the bottom surface of the bag body 6, the side of the bag body 5 is a double-layer folded layer, and the top of the bag body side 5 is sealed and arranged on the inner side of the bag body rear 4 through a sealing paper 18, and a zipper mechanism 7 is sealed at the top seal of the bag body front 3, and the zipper mechanism 7 includes a convex The strip paper 8 and the concave strip paper 9, the convex strip paper 8 is provided with a convex strip 10, and the concave strip paper 9 is provided with a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com