A retarding high-fluidity high-strength underwater concrete additive and preparation method thereof

An underwater concrete and high fluidity technology, applied in the field of building materials, can solve problems such as not suitable for long-distance transportation and construction, lack of research on durability such as permeability, and unsatisfactory concrete material systems, so as to improve volume stability and durability, improving volume stability, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

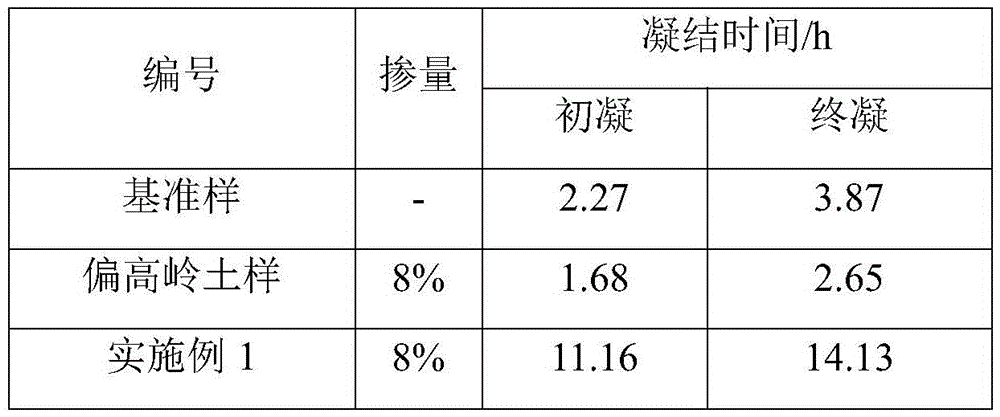

[0021] A retarding type high-fluidity high-strength underwater concrete additive, which is obtained by grinding metakaolin and a composite modifier in a ball mill for 30 minutes, wherein the mass ratio of metakaolin to the composite modifier is 15:1, the described The composite modifying agent is prepared by mixing polyacrylamide, polycarboxylate water reducer and sucrose in the order of 80%, 15% and 5% by mass.

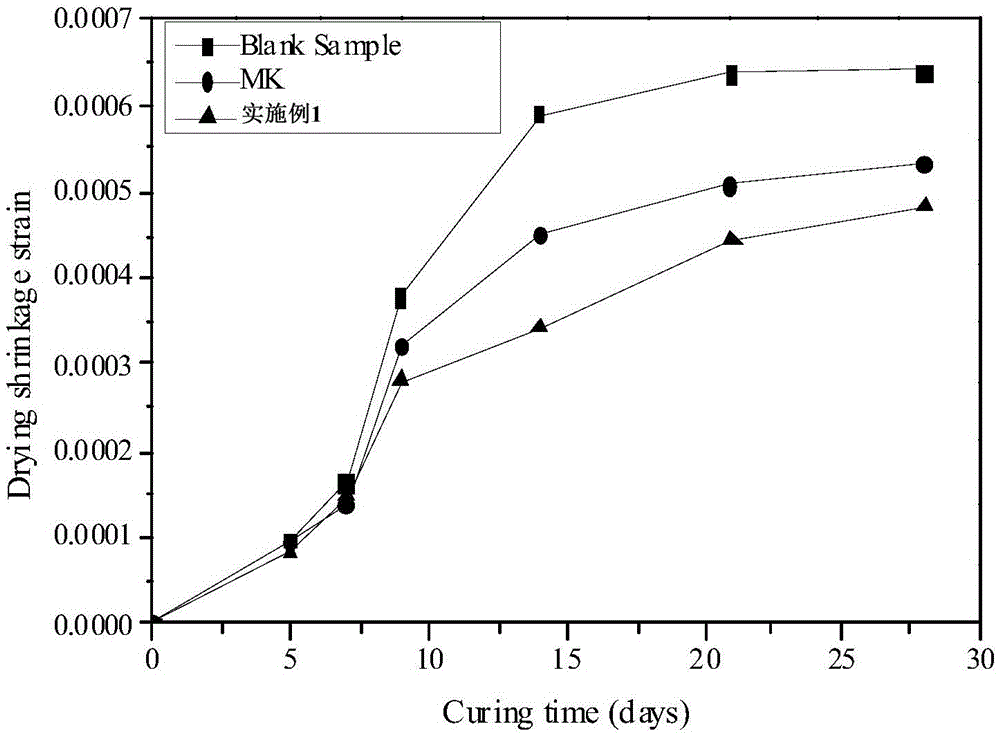

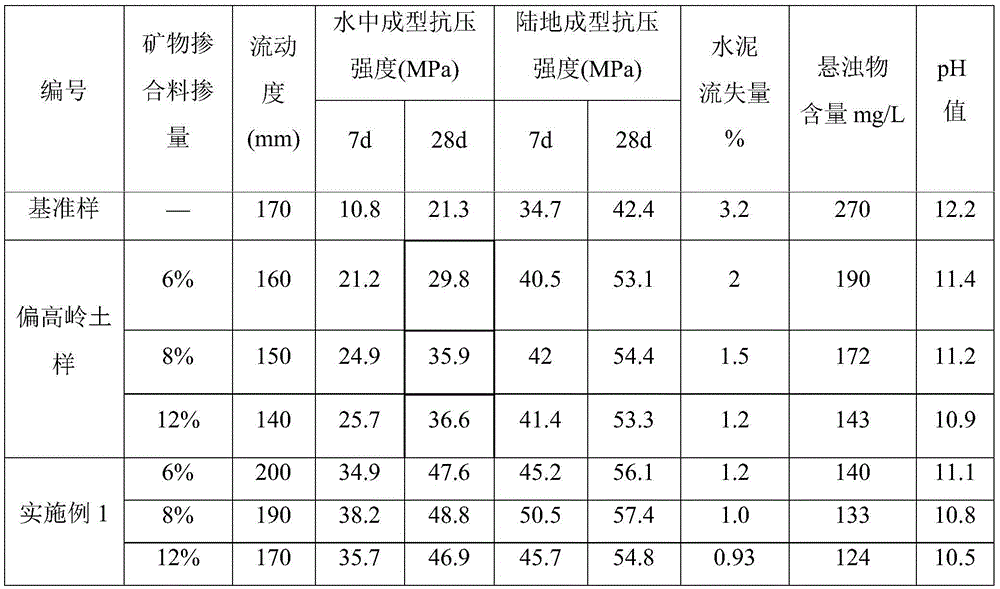

[0022] Taking the mortar specimen as the object of investigation, metakaolin was used to replace the cementitious material with 6%, 8%, and 12% respectively, and 1% water reducing agent was added to prepare the mortar. River sand (passed through a 2.36mm sieve) and the retarded high-fluidity high-strength underwater concrete additive of Example 1 were added at 6%, 8%, and 12% respectively, and the water-cement ratio was 0.45.

[0023] According to GB / T2429-2005 "Cement Mortar Fluidity Measurement Method" test the fluidity of the mixture of the reference sample, metak...

Embodiment 2

[0034] A retarding type high-fluidity high-strength underwater concrete additive, which is ground in a ball mill for 120 minutes by metakaolin and a composite modifier, wherein the mass ratio of metakaolin to the composite modifier is 20:1, and the composite The modifying agent is prepared by mixing polyacrylamide, polycarboxylate water reducer and sucrose in the order of 75%, 20% and 5% by mass.

[0035] Taking the concrete specimen as the object of investigation, the additives in Example 2 are used to replace the cementitious material in an equivalent amount of 10% to configure the concrete. Slump and expansion; according to GB / T50081-2002 "Standard for Test Methods of Mechanical Properties of Ordinary Concrete", test the benchmark sample and the additives of Example 2 with a universal pressure testing machine for 7 days and 28 days compressive strength; Concrete anti-dispersion test According to Q / CNPC92-2003. The cement loss was 1.1%, the pH was 11.2, and the suspended ma...

Embodiment 3

[0037] A retarding type high-fluidity high-strength underwater concrete additive, which is obtained by grinding metakaolin and a composite modifier for 90 minutes in a ball mill, wherein the mass ratio of metakaolin to the composite modifier is 30:1, the described The composite modifier is prepared by mixing polyacrylamide, polycarboxylate water reducer and sucrose in the order of 70%, 25% and 5% by mass.

[0038] Taking the concrete specimen as the object of investigation, the metakaolin-based additive was used to replace the cementitious material in an equivalent amount of 12% to configure the concrete, and the slump and Expansion degree; in accordance with GB / T50081-2002 "Standard for Test Methods of Mechanical Properties of Ordinary Concrete", use a universal pressure testing machine to test the 7-day and 28-day compressive strength of the reference sample and the example; the concrete dispersion resistance test is in accordance with Q / CNPC92-2003 conduct. The loss of cem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com