Double nozzle semi-automatic glazing device

A semi-automatic, dual-nozzle technology, applied in the field of glazing devices for ceramic products, can solve problems such as uneven thickness of the glaze layer of the product, failure of glazing at both ends of the product, affecting the glazing quality of the product, etc., achieving convenient maintenance and cleaning, and simple product structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

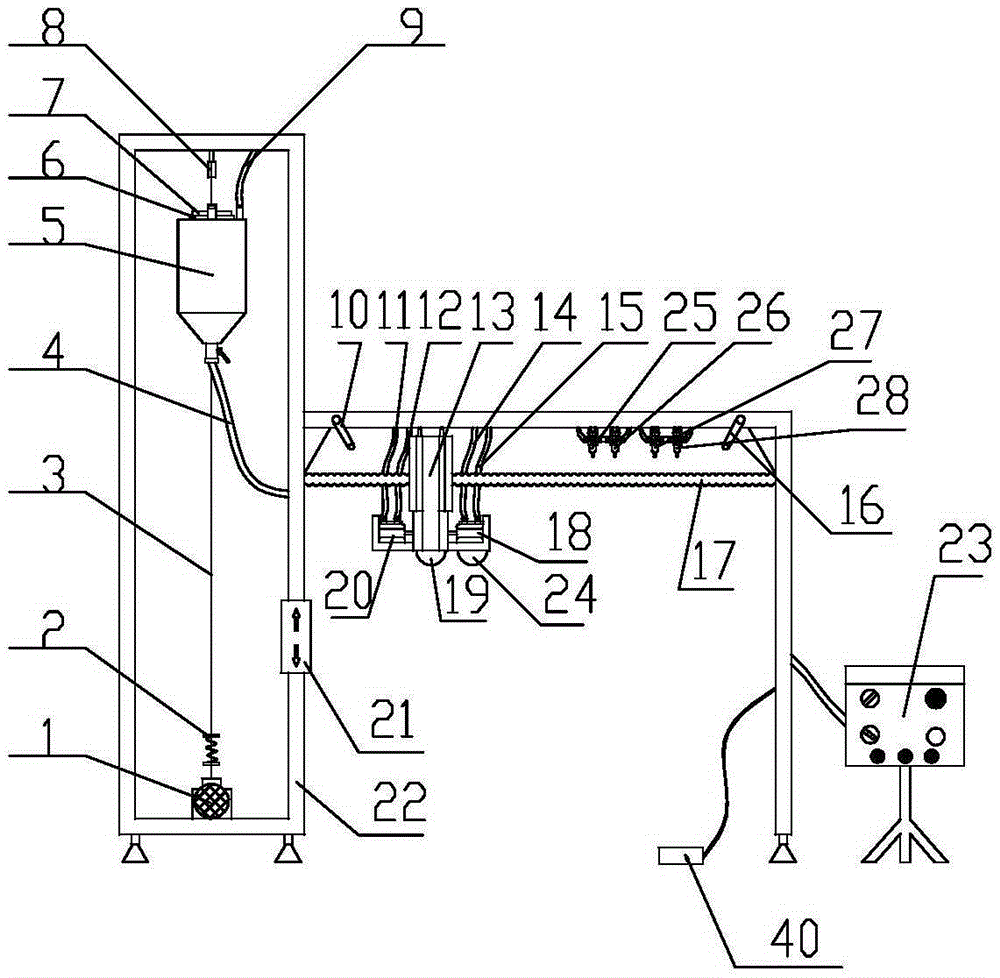

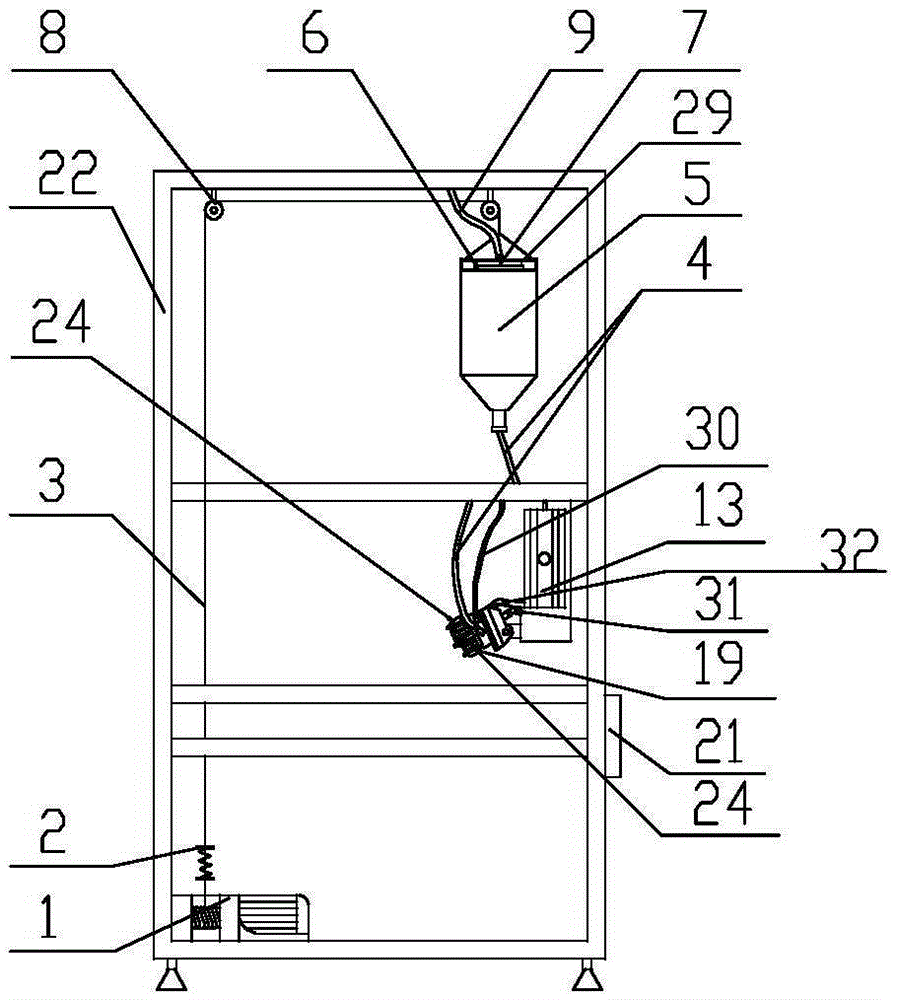

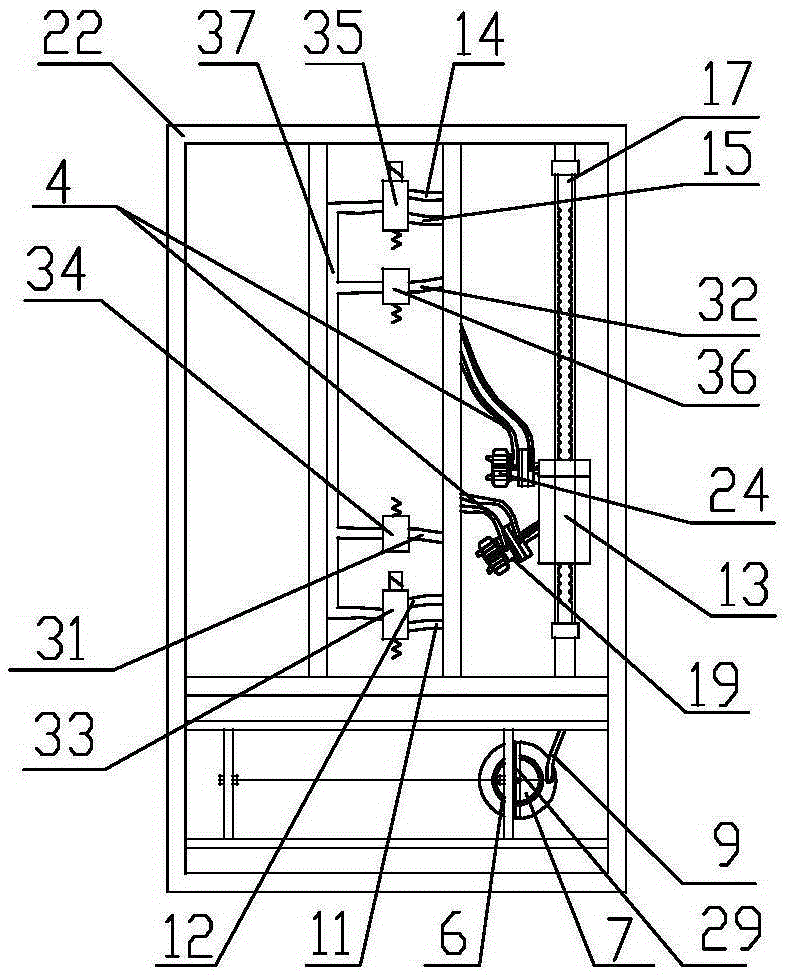

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Figure 1~4 Including the first motor 1, spring 2, steel wire rope 3, feeding pipe 4, storage barrel 5, sealing ring 6, sealing cover 7, roller 8, pressurizing pipe 9, first travel switch 10, first air pipe 11 , the second air pipe 12, the second motor 13, the third air pipe 14, the fourth air pipe 15, the second stroke switch 16, the screw mandrel 17, the first air cylinder 18, the first spray gun 19, the second air cylinder 20, the motor control switch 21 , frame 22, electrical control cabinet 23, second spray gun 24, glaze bucket pressure regulating valve 25, nozzle pressure regulating valve 26, cylinder pressure regulating valve 27, total air pressure valve 28, ejector rod 29, fifth air pipe 30, sixth Air pipe 31, seventh air pipe 32, first electromagnetic valve 33, second electromagnetic valve 34, third electromagnetic valve 35,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com