Silicone resin composite material as well as manufacturing method and application of silicone resin composite material and lighting device

A technology of composite materials and lighting devices, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as spatial chromaticity unevenness, achieve good luminous performance, and improve the effect of mixing uniformity

Active Publication Date: 2014-10-29

FLORY OPTOELECTRONICS MATERIALS SUZHOU CO LTD

View PDF1 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0011] However, quantum dots still have many problems in terms of color, lifespan, cost and large-scale quantitative production that need

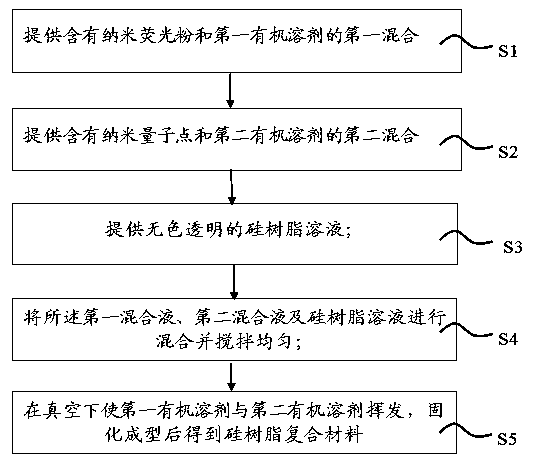

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

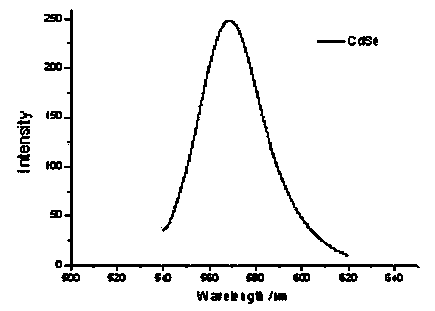

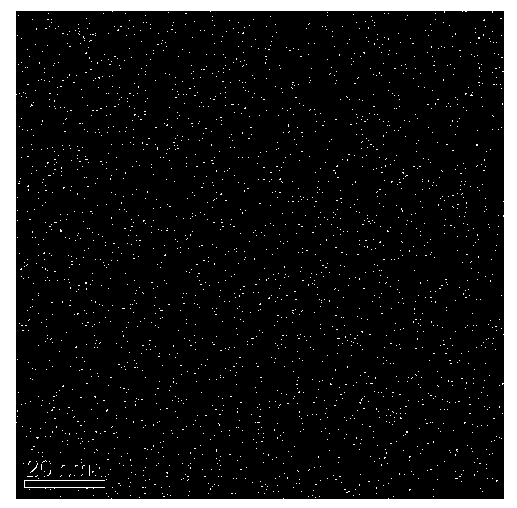

The invention relates to a silicone resin composite material. The silicone resin composite material comprises nano-fluorescent powder, nano quantum dots and colorless and transparent silicone resin, wherein nano-fluorescent powder and nano quantum dots are uniformly dispersed in colorless and transparent silicone resin, the silicone resin composite material is in a cured structure, nano-fluorescent powder and nano quantum dots are the luminescent material and the silicone resin is a first packaging material. The invention also discloses a manufacturing method of the silicone resin composite material, a lighting device comprising the silicone resin composite material, and an application of the silicone resin composite material as the lighting device. The silicone resin composite material disclosed by the invention has the beneficial effects that by virtue of mixing the nanoscale fluorescent powder with nanoscale quantum dots, the silicone resin composite material prepared by the invention has an improved mixing uniformity and good luminescence property and is suitable for a photoelectric device or an LED solid lighting device and the packaging of the photoelectric device or LED solid lighting device.

Description

technical field [0001] The invention relates to a silicone resin composite material, a manufacturing method of the silicone resin composite material, a lighting device containing the silicone resin composite material, and an application of the silicone resin composite material as a lighting device, belonging to the fields of lighting and lighting. Background technique [0002] With the global energy crisis and the gradual enhancement of people's awareness of energy conservation and environmental protection, a large amount of energy-saving and environmentally friendly green energy has entered our lives. Light-emitting diodes (LEDs) are gradually replacing traditional lighting materials and becoming a new generation of lighting sources due to their advantages such as low energy consumption, low heat generation, and long life. [0003] However, with the continuous improvement of brightness and power, fluorescent materials and packaging materials have become one of the key techn...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L83/04C08L63/00C08K3/30C08K3/22H01L33/56

Inventor 张汝志葛广路

Owner FLORY OPTOELECTRONICS MATERIALS SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com