Intelligent hydraulic cross-linked suspension system

A cross-linked suspension system, hydraulic technology, applied in the direction of fluid pressure actuators, springs, shock absorbers, etc., can solve the problem of being unable to take into account various complex driving conditions, intelligently change the cross-linking mode, and cannot adapt to driving conditions and other problems, to achieve the effect of low processing and installation accuracy, simple structure, and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

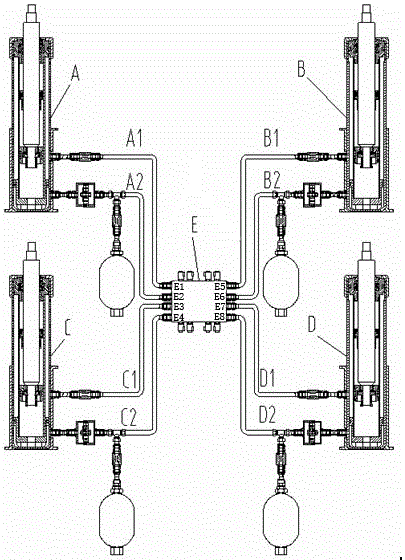

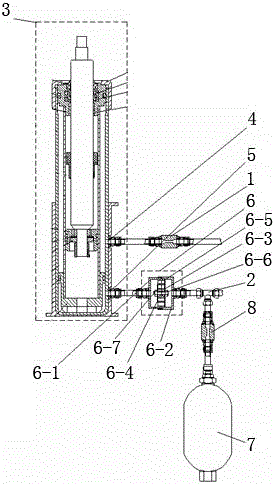

[0020] Such as Figure 5 , 6 As shown, the first cross-linking mode of the intelligent hydraulic cross-linking suspension system: A1 is connected to C1, B2, and D2, and A2 is connected to C2, B1, and D1. This is the default connection mode of the intelligent hydraulic cross-linking suspension system. In this cross-linking mode, when the vehicle moves vertically, the oil flow through the throttle valve 8 on the pipeline of the accumulator 7 is discharged from the area of the piston rod, and the flow is small, so the vertical damping force generated is very small ; When the vehicle is doing roll motion, due to the left and right cross connections, the oil flow through the throttle valve 8 on the pipeline of the accumulator 7 is discharged by the sum of the area of the rodless cavity and the area of the rod cavity, and the flow is very large, so it will Produces very large roll angle damping, suppressing excessive body roll motion. When the vehicle passes through a rough ...

Embodiment 2

[0022] Such as Figure 7 , 8 Shown: The second cross-linking method of the intelligent hydraulic cross-linking suspension system: A1 is connected to D2, A2 is connected to D1, B1 is connected to C2, and B2 is connected to C1. This cross-linking method is equivalent to the vehicle having two pairs of left and right Cross and two pairs of front and rear cross shock absorber groups, the roll and pitch motion of the body will produce a large dip angle damping, so the vehicle has high roll and pitch stability, which can prevent the vehicle from accelerating, braking or Excessive body inclination is generated when steering, which improves the posture stability and ride comfort of the body. The use of this cross-linking method when the vehicle starts and brakes can reduce the phenomenon of starting and braking nodding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com