Detection device and method for olefin gas

A detection device and detection method technology, applied in the direction of transmittance measurement, etc., can solve problems such as safety accidents and production losses, and achieve the effect of accurate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

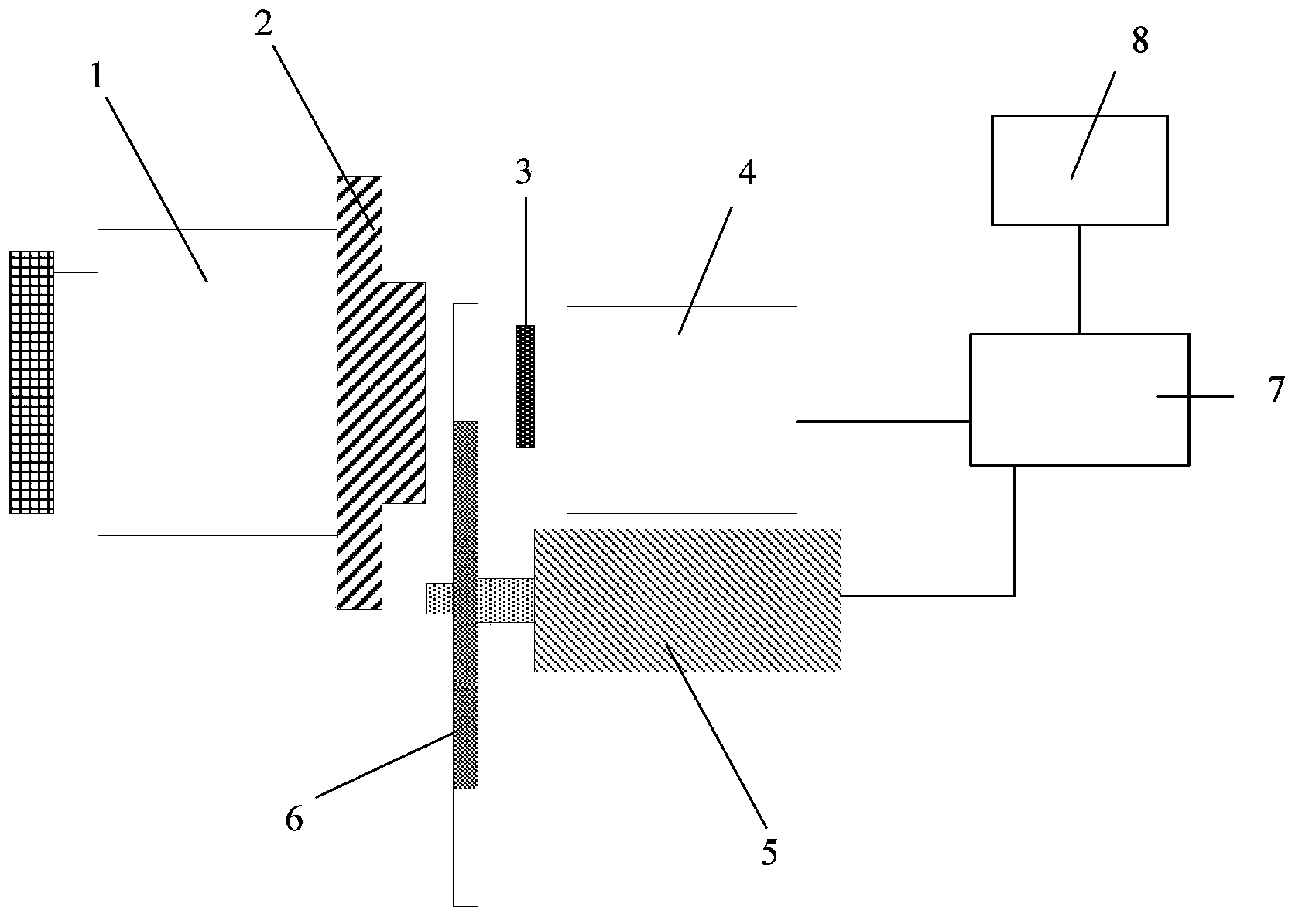

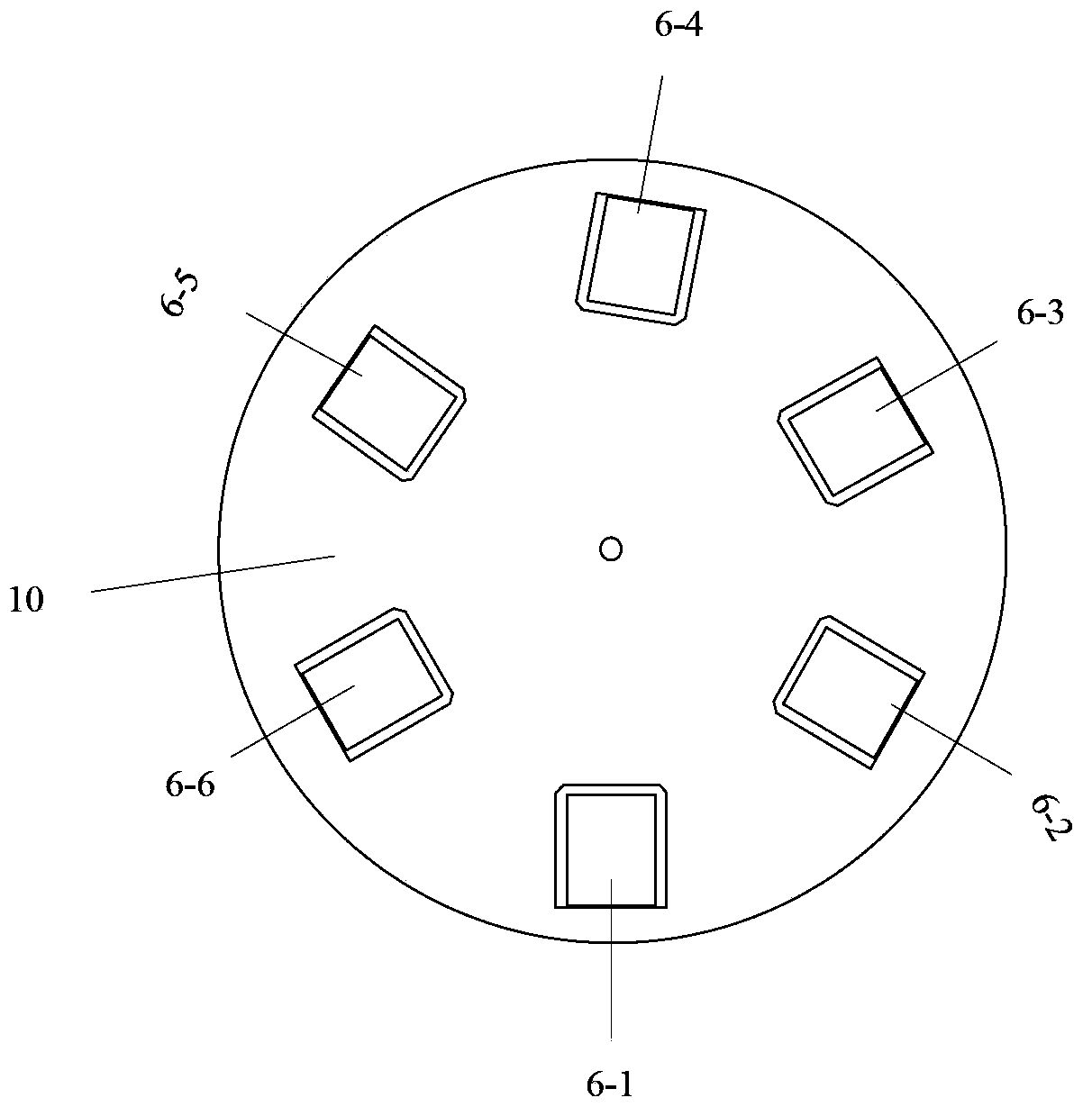

[0034] This embodiment discloses a detection device and detection method for olefin gas, figure 1 It is a schematic structural diagram of the detection device for olefin gas in this embodiment. Such as figure 1 As shown, the detection device includes an infrared lens 1 , a lens interface 2 , an olefin gas identifier 6 , an infrared detector 3 , a processing circuit 4 , an encoding motor 5 , a monitoring and analysis unit 7 , and a display 8 . The infrared lens 1 is used to focus the infrared radiation signal of the gas in the environment to be measured and the background. The olefin gas identifier is arranged between the infrared lens 1 and the infrared detector 3. The olefin gas identifier includes a turntable 10 and an Olefin bandpass filters and blackbody windows. figure 2 It is a top view structure schematic diagram of the olefin gas identifier 6 .

[0035] The turntable 10 of the olefin gas identifier 6 is provided with: a blackbody window 6-1, a first olefin bandpass...

Embodiment 2

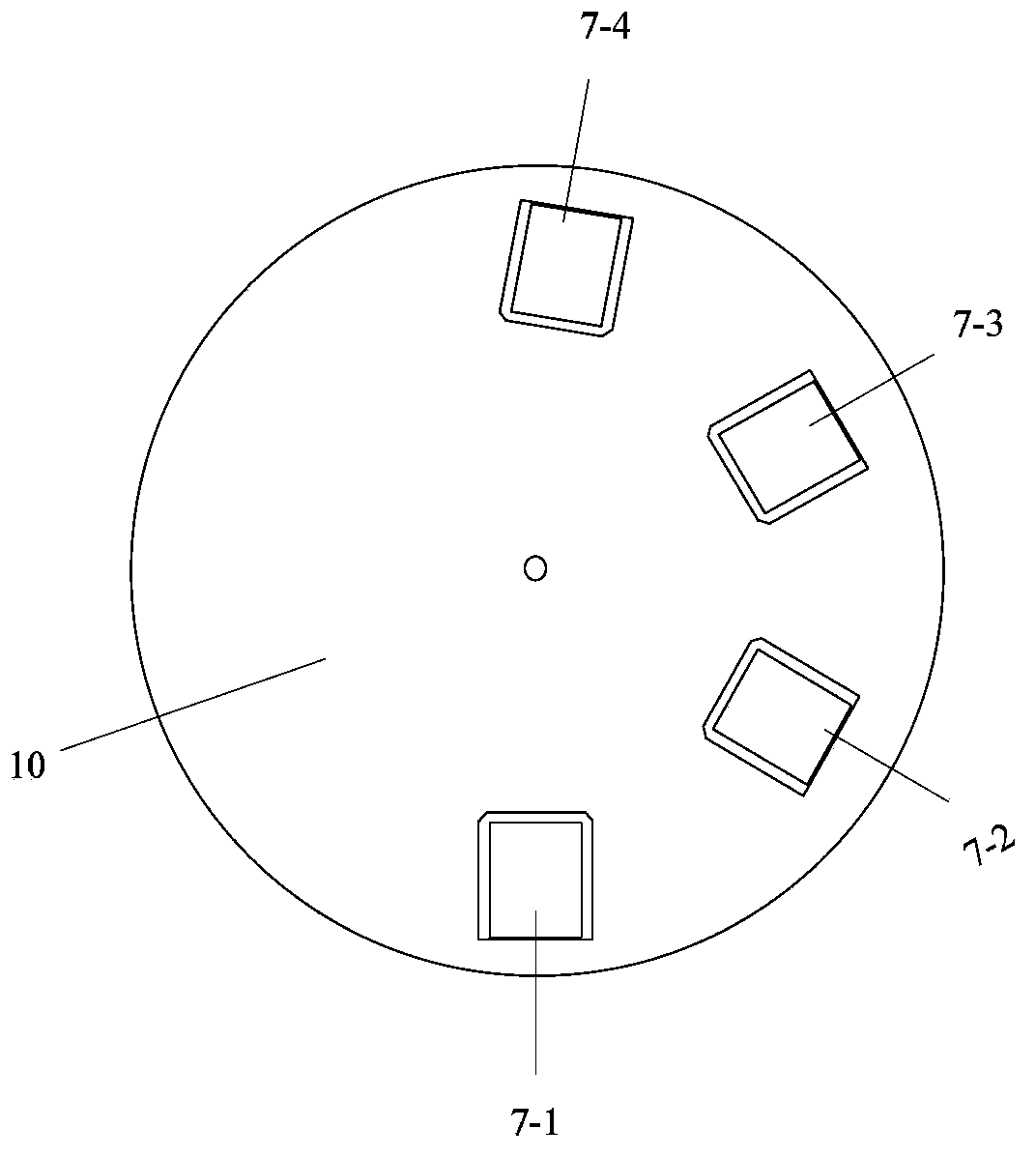

[0049] This embodiment discloses another olefin gas detection device and detection method. The detection device includes an infrared lens, a lens interface, an olefin gas identifier, an infrared detector, a processing circuit, an encoding motor, a monitoring and analysis unit, and a display. These are the same as those in the first embodiment, except that three olefin bandpass filters are arranged on the turntable of the olefin gas identifier. image 3 It is a schematic diagram of the top view structure of the olefin gas identifier.

[0050] The turntable of the olefin gas identifier includes: black body window 7-1, the first olefin bandpass filter 7-2, its center wavelength is 10.1 ± 0.020 microns, the second olefin bandpass filter 7-3, its center wavelength is 10.99±0.02 microns, and the third olefin bandpass filter 7-4 has a central wavelength of 12.28±0.02 microns. image 3 Fig. 1 schematically shows the distribution of the three olefin bandpass filters on the turntable ...

Embodiment 3

[0062] This embodiment discloses another olefin gas detection device and detection method. The detection device includes an infrared lens, a lens interface, an olefin gas identifier, an infrared detector, a processing circuit, an encoding motor, a monitoring and analysis unit, and a display. These are the same as those in the first embodiment, except that two olefin bandpass filters are arranged on the turntable of the olefin gas identifier. Figure 4 It is a schematic diagram of the top view structure of the olefin gas identifier.

[0063] The turntable of the olefin gas discriminator includes a blackbody window 8-1, a first olefin bandpass filter 8-2 with a center wavelength of 3.24 ± 0.02 microns, and a second olefin bandpass filter 8-3 with a center wavelength of 3.31 ± 0.02 microns. The passband lengths of the two olefin bandpass filters are both 100±20nm. The olefin bandpass filter selected in this embodiment is a medium-wave filter, and correspondingly, the infrared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com