Multiway LED constant current controller and control method

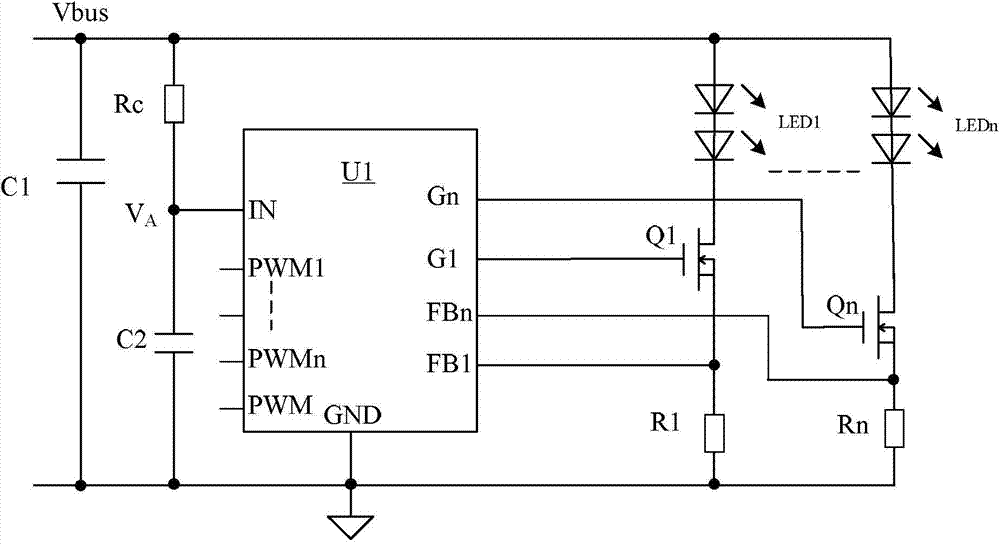

A current controller and constant current control technology, which is applied in the direction of lamp circuit layout, electrical components, electroluminescence light source, etc., can solve the load state change, the influence of constant current control accuracy and efficiency, and the loop response speed cannot adapt to the load state To improve the transient response speed and speed up the loop response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

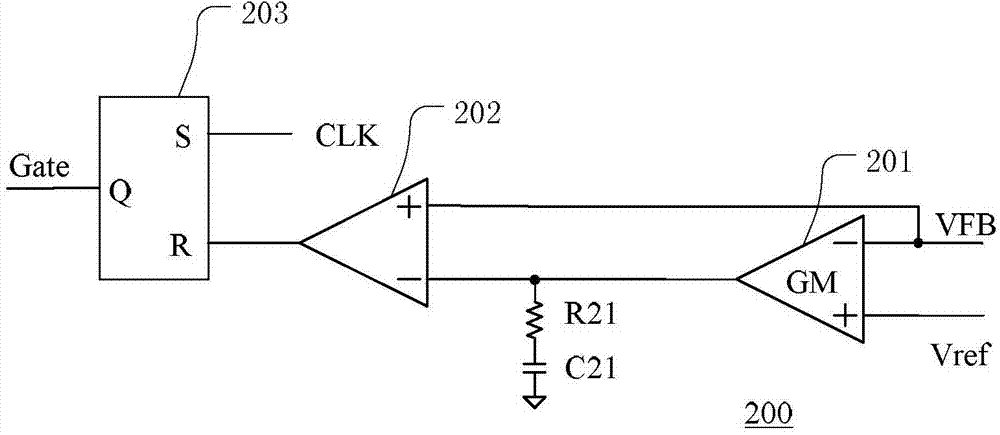

[0046] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

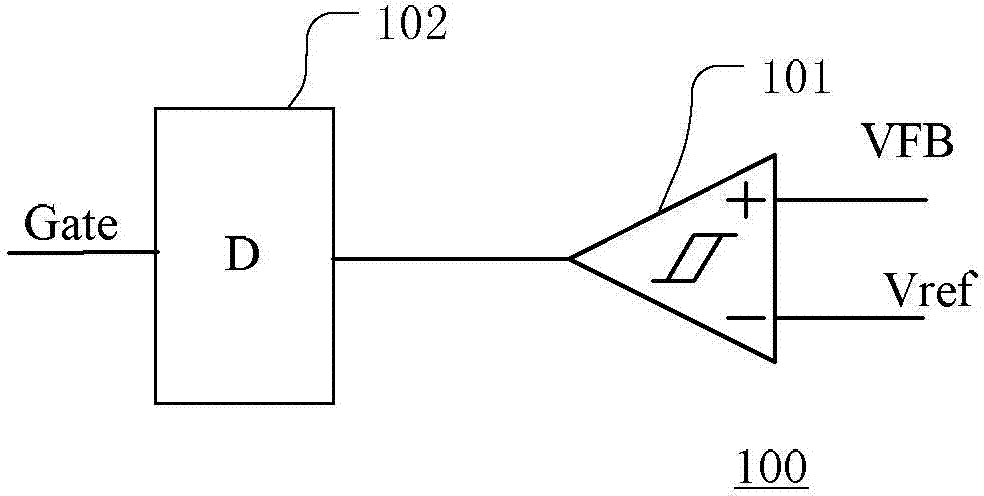

[0047] refer to figure 2 , which shows a schematic circuit diagram of an LED constant current controller 100 using a hysteresis control method according to the prior art. The LED constant current controller 100 includes a hysteresis comparator 101 and a flip-flop 102 . The non-inverting terminal of the hysteresis comparator 101 is connected to an external current sampling unit (such as a sampling resistor) to receive a current feedback signal VFB, and the inverting terminal receives a reference voltage Vref. The output terminal of the hysteresis comparator 101 is connected to a flip-flop 102 . The output end of the flip-flop 102 is connected to an external power sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com