a chicken shed

A technology for a greenhouse and a shed body is applied in the field of chicken-raising greenhouses, which can solve the problems of low quality, small eggs, and low egg production rate of chickens, so as to reduce the use of chemical fertilizers, prolong the service life, and improve the egg production rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

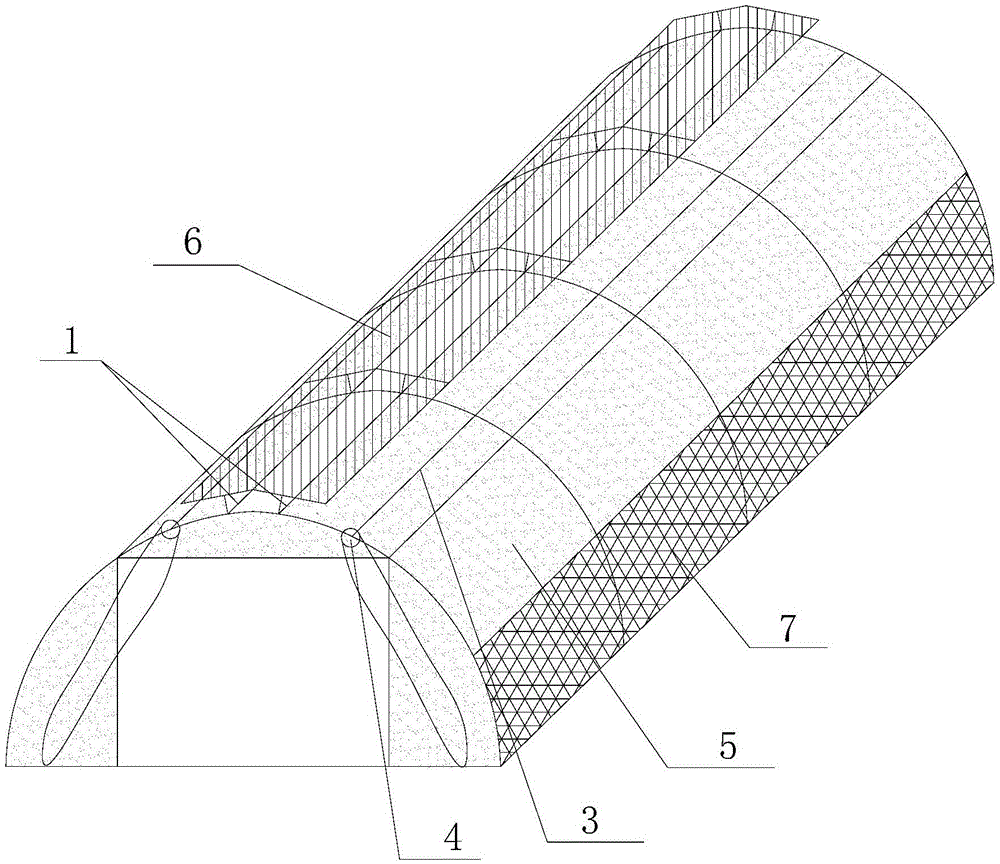

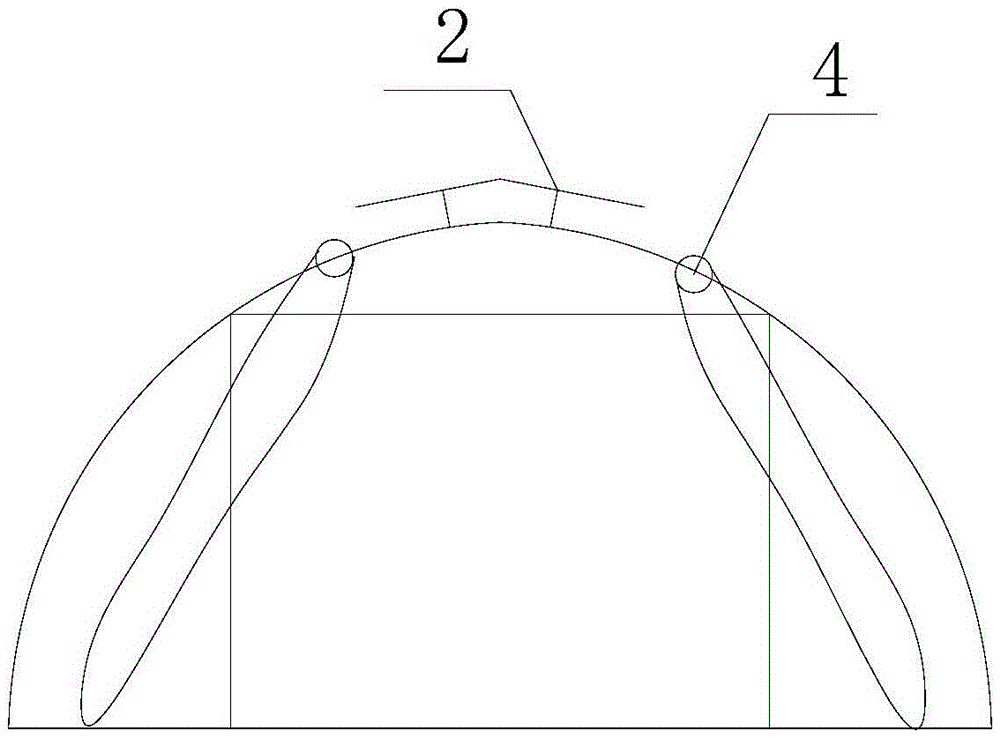

[0019] Embodiment 1: as figure 1 and figure 2 As shown, a chicken shed includes a shed body, and the shed body includes two first horizontal frames 1 and a plurality of arch frames arranged in front and rear order, and the two first horizontal frames 1 are respectively arranged on both sides of the top of the shed body; Two supports vertically connected to the shed body are installed on the top of the shed body, and a triangular top 2 is arranged on the two supports; a rotating shaft 3 is arranged on the shed body and under each first horizontal frame 1, The rotating shaft 3 is arranged along the length direction of the shed body, and one end of each rotating shaft 3 is connected with a rotating device 4; the distance between the two first horizontal frames 1 is smaller than the distance between the bottom of the two hypotenuses of the triangular top 2; Barbed wire 7 is installed on the bottom of both sides of the body, and the first plastic film 5 is covered between the upp...

Embodiment 2

[0029] It is basically the same as Embodiment 1, except that the fermented product includes the following components in parts by weight: 60 parts of vinegar grains, 20 parts of rice husk, 20 parts of bran, 10 parts of laying hen compound premix, fermentation bed strain 10 parts, 5 parts of soybean meal, 8 parts of rapeseed cake, 3 parts of minced garlic. During preparation, weigh according to the amount of each component, then firstly mix vinegar grains, bran, rice husk and fermentation bed strains evenly, and then spread them on the ground with a thickness of 10 cm to obtain a fermentation layer; Turn the pile once a day, and turn the pile 3 times in total; after the pile is finished, mix the laying hen compound premix, soybean meal, rapeseed cake and minced garlic evenly and spread it on the fermentation layer; continue to turn the pile until the material is warm After no further changes, mix all materials evenly every 12 days.

Embodiment 3

[0031] It is basically the same as Embodiment 1, except that the fermented product includes the following components in parts by weight: 70 parts of vinegar grains, 30 parts of rice husk, 30 parts of bran, 20 parts of laying hen compound premix, fermentation bed strain 15 parts, 10 parts of soybean meal, 12 parts of rapeseed cake, 5 parts of minced garlic. When preparing, weigh according to the amount of each component, then firstly mix the vinegar grains, bran, rice husk and fermentation bed strains evenly, and then spread them on the ground. The thickness of the laying is 12cm to obtain a fermentation layer; Turn the pile once every 2 days, and turn the pile 4 times in total; after the pile is finished, mix the laying hen compound premix, soybean meal, rapeseed cake and minced garlic evenly and spread it on the fermentation layer; continue to turn the pile until the material is warm After no further changes, mix all materials evenly every 15 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com