Juice extractor

A juicer and lower seat technology, which is applied in the field of juicer, can solve the problems of high production cost, wear and tear of connectors, etc., and achieve the effects of prolonging the service life, improving the heat dissipation effect, and improving the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

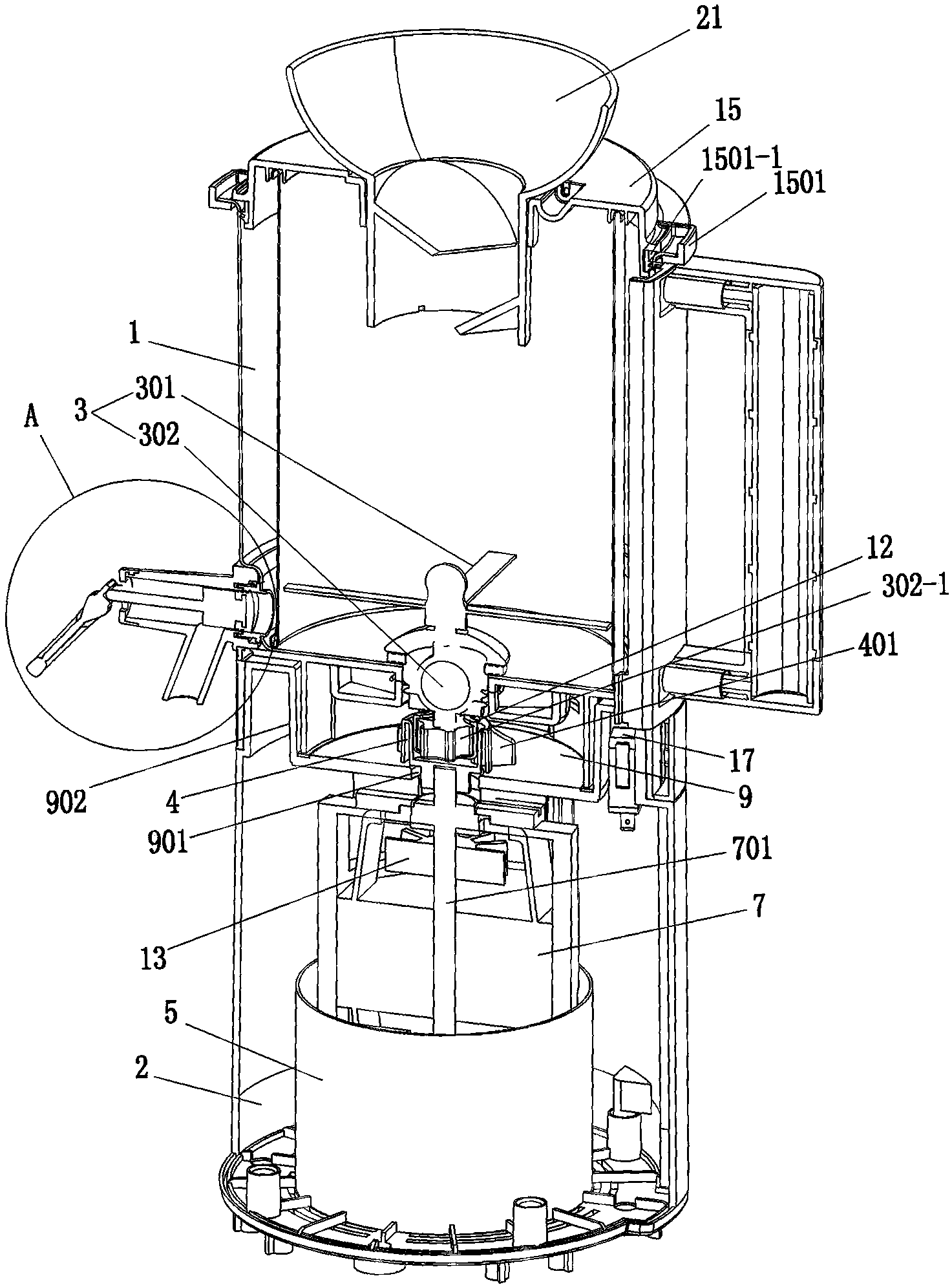

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

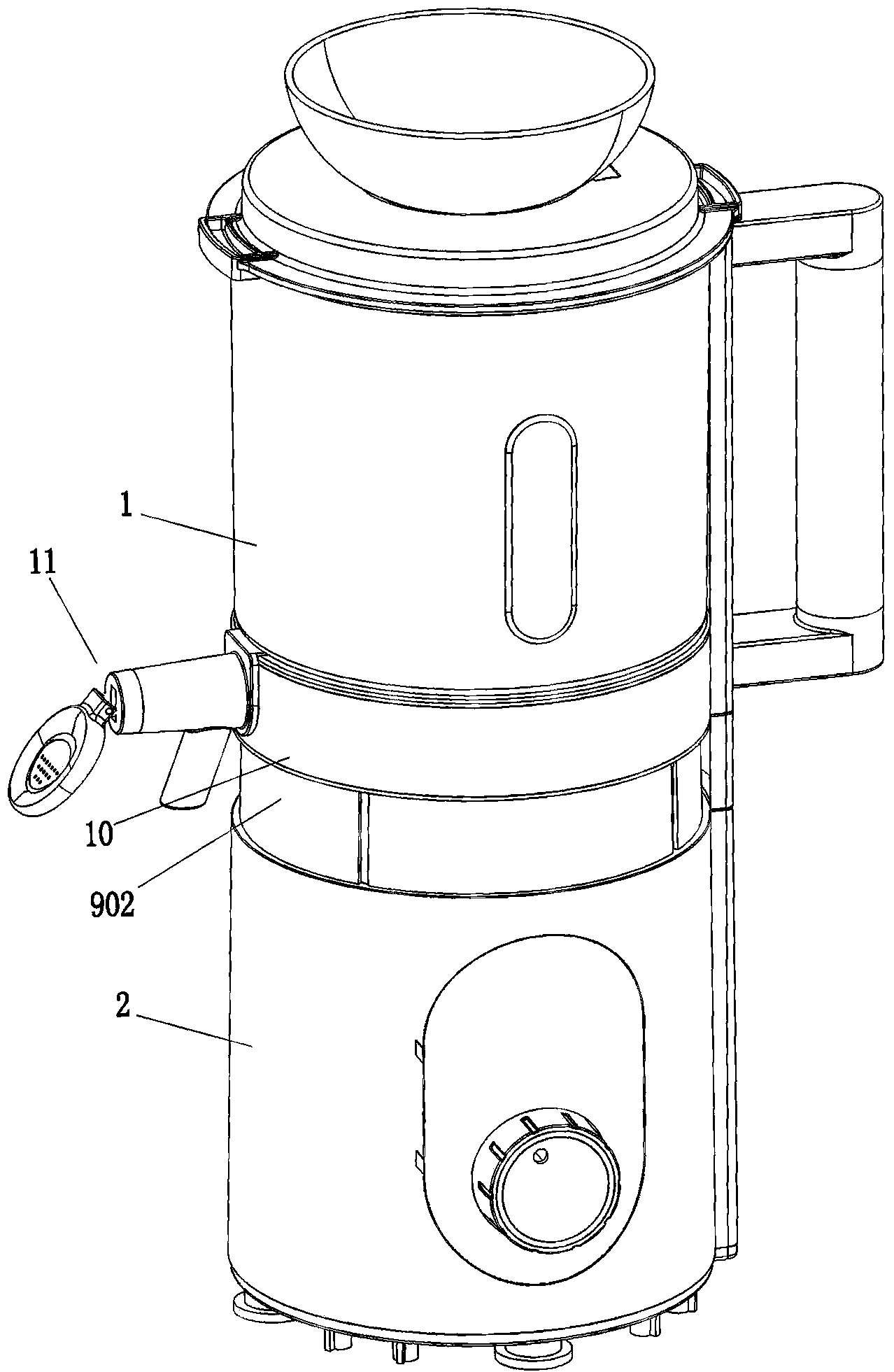

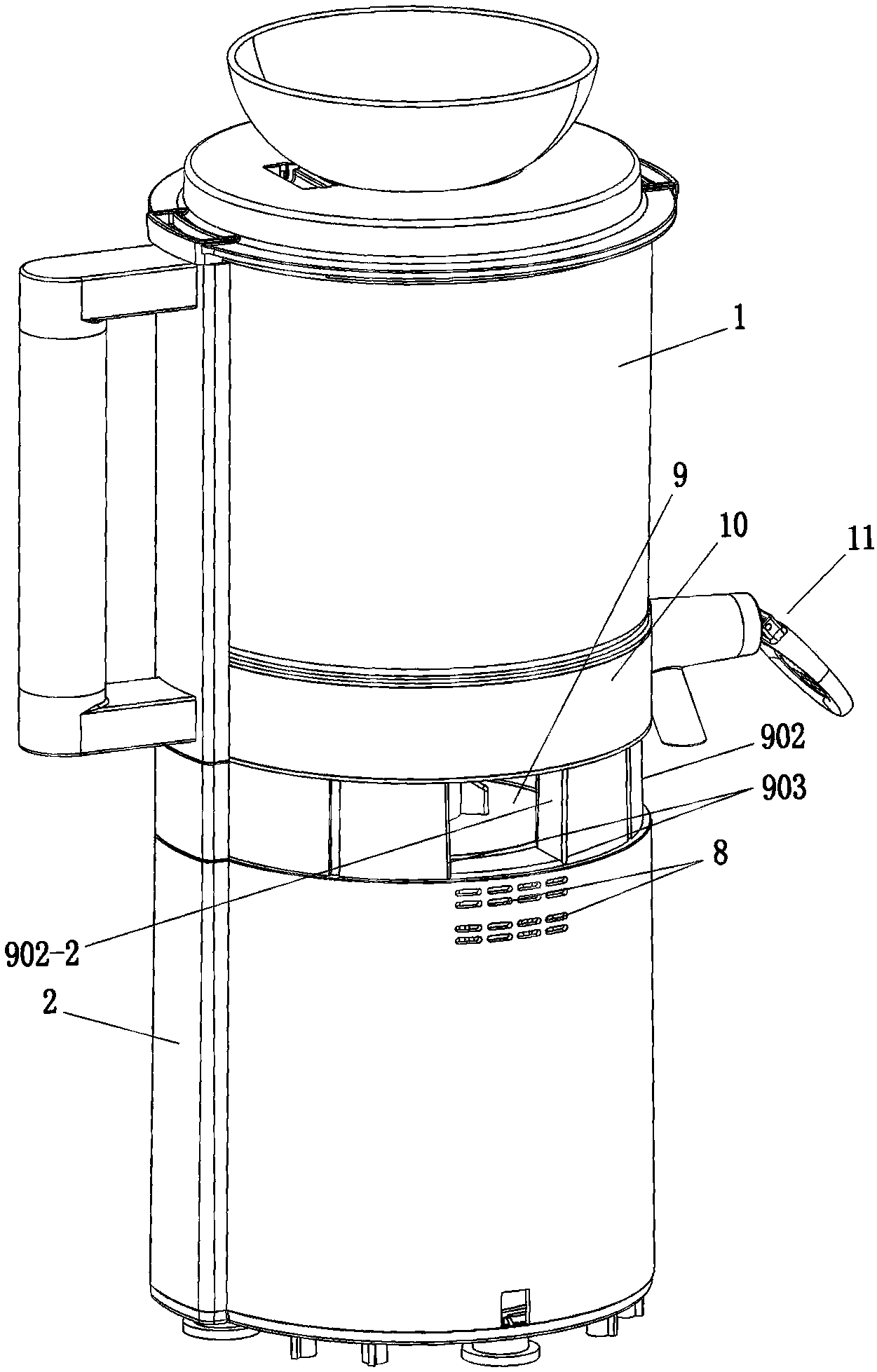

[0043] like Figure 1 to Figure 14 As shown, a juice extractor includes an upper barrel 1 and a lower seat 2 that are connected up and down in a detachable manner, a mixing knife structure 3 is installed on the bottom of the upper barrel 1, and a hinged connection with the stirring knife structure 3 is installed on the lower seat 1 The shaft sleeve 4 is characterized in that the bottom of the lower seat 2 is provided with an air guide tube 5 along the height extension direction, and the bottom of the lower seat 2 corresponding to the bottom of the air guide tube 5 is provided with a first air inlet 6, and the air guide tube 5 is installed There is a motor 7, and the side wall of the lower seat 2 is provided with a first air outlet 8 that communicates with the first air inlet 6;

[0044] The top of the lower seat 2 is provided with a heat dissipation ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com