A pump installation tooling platform

A tooling table and mounting seat technology, which is applied to workbenches, assembly machines, manufacturing tools, etc., can solve the problems of laborious and time-consuming operations, easy flipping and rolling, and a single type of compatible pump, and achieve simple, labor-saving, and supportive effects The effect of stabilizing and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

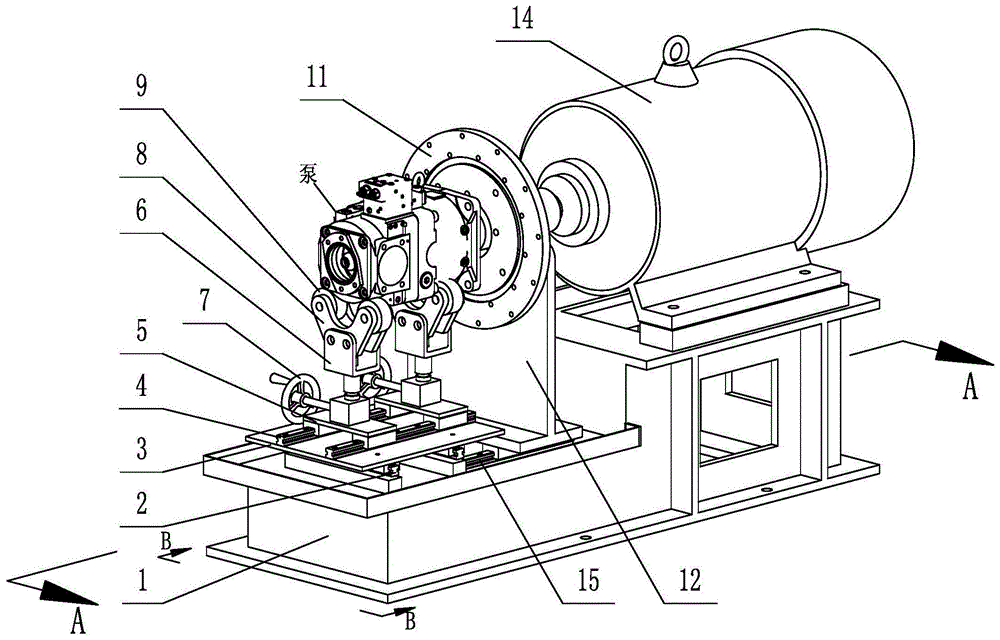

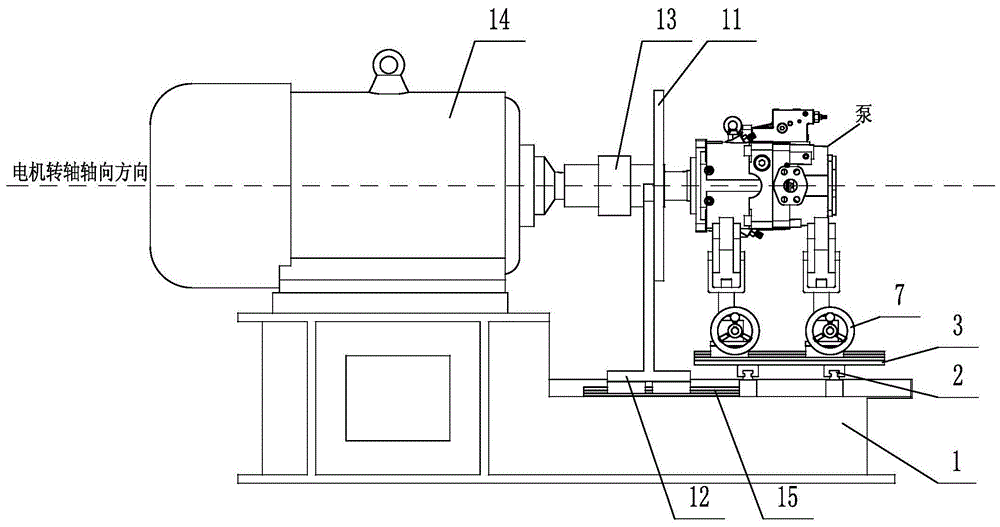

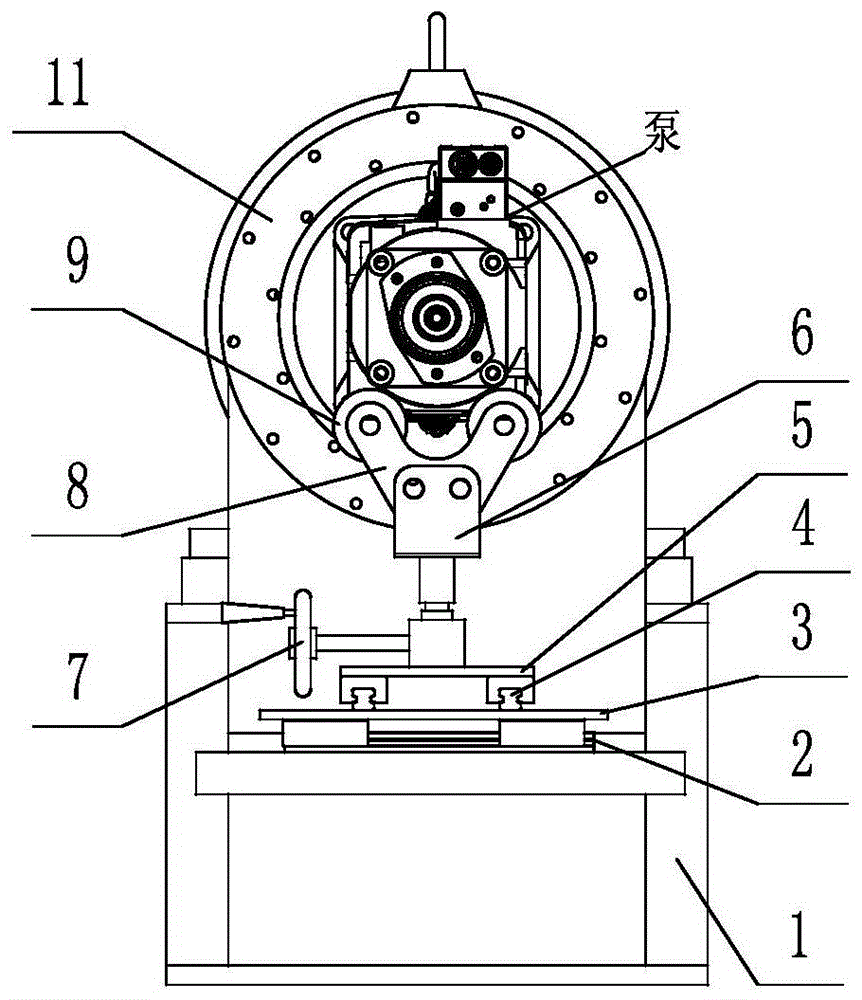

[0032] The following will further elaborate on the pump installation platform of the present invention in conjunction with the accompanying drawings and specific embodiments.

[0033] as attached Figure 1~3 As shown, the pump installation tooling platform of this embodiment includes a tooling platform base 1;

[0034] The motor 14 fixedly arranged on the base 1 of the tooling table, and the first slide rail 2 arranged in the vertical direction along the axis of the motor 14, the first slide rail 2 is composed of two parallel slide rails;

[0035] The bottom is provided with the second slide rail fixing plate 3 of the slider matched with the first slide rail 2; the second slide rail fixing plate 3 is also provided with a locking device that can prevent it from sliding along the first slide rail 2 , the locking device is specifically a nut that can be screwed against the first slide rail 2 to prevent its sliding;

[0036] The second slide rail 4 fixedly arranged on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com