Blow molding machine preform variable pitch device

A technology of variable pitch and bottle blowing machine, applied in the field of variable pitch devices, can solve the problems of slow action response, asynchronous change of pitch of preforms, increase of reject rate, etc., and achieve the effect of avoiding sticking, changing pitch synchronously, and improving the yield of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific examples.

[0025] The upstream and downstream described in this embodiment are determined by the running direction of the preform 6, as figure 1 As mentioned above, the left side of the diagram is downstream, and the right side is upstream.

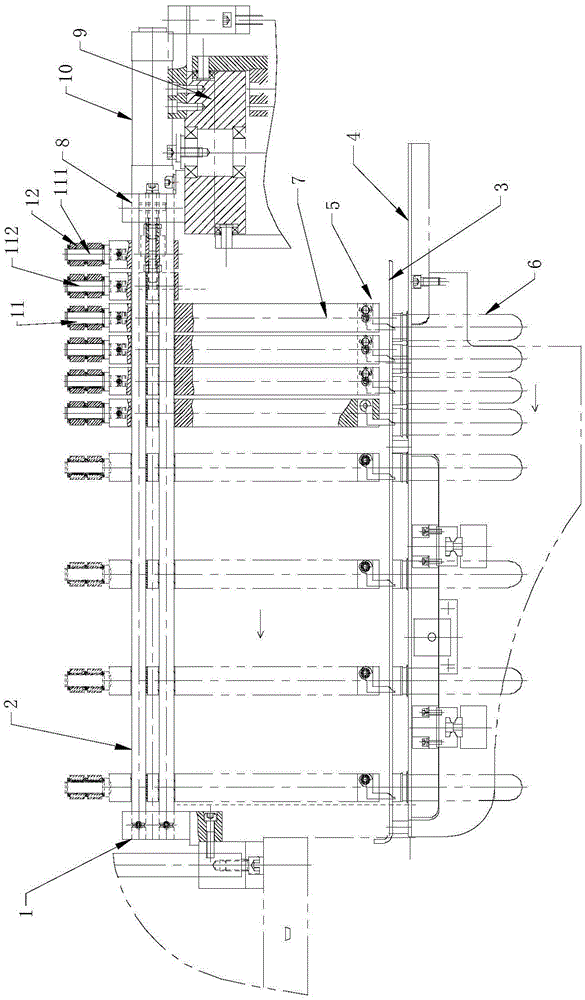

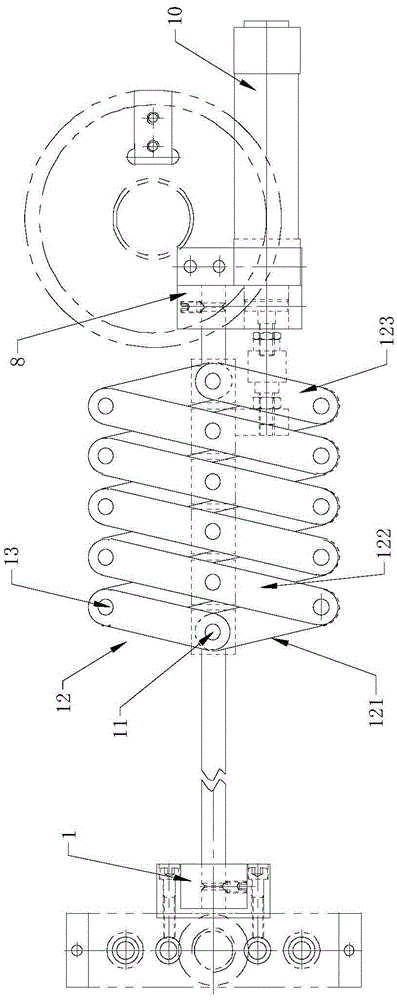

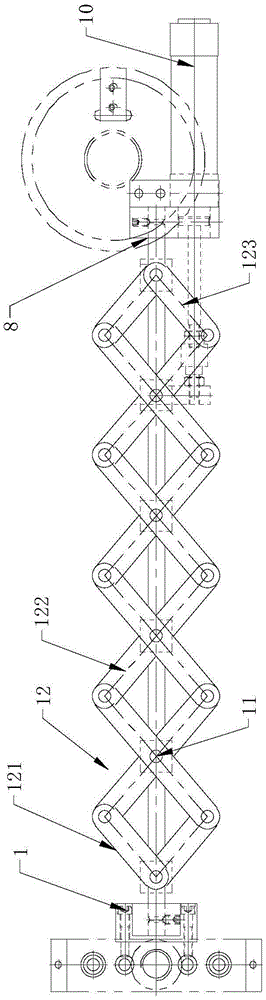

[0026] Such as figure 1 , 2 , 3 and 6, a bottle blank variable pitch device for bottle blowing machine, the variable pitch device is installed between the outlet of the heating device of the bottle blowing machine and the blowing mold, the variable pitch device includes guide rods 2, several Connecting rod 12, several push rods 7, several sets of preform clamping mechanisms 5, linear drive device 10. After the preform 6 is heated in the heating box, it will be led out through the guide plate 4. The guide plate 4 is provided with a guide groove to facilitate the sliding of the preform 6. The preform 6 is in the guide groove and the annular convex ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com