A kind of bar automatic packing chain device

An automatic, bar technology, applied in the field of steel rolling, can solve the problems of affecting the production rhythm of the bar production line, increasing the transfer time of the finished bar, and affecting the production efficiency of the bar, so as to save manpower, eliminate potential safety hazards and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

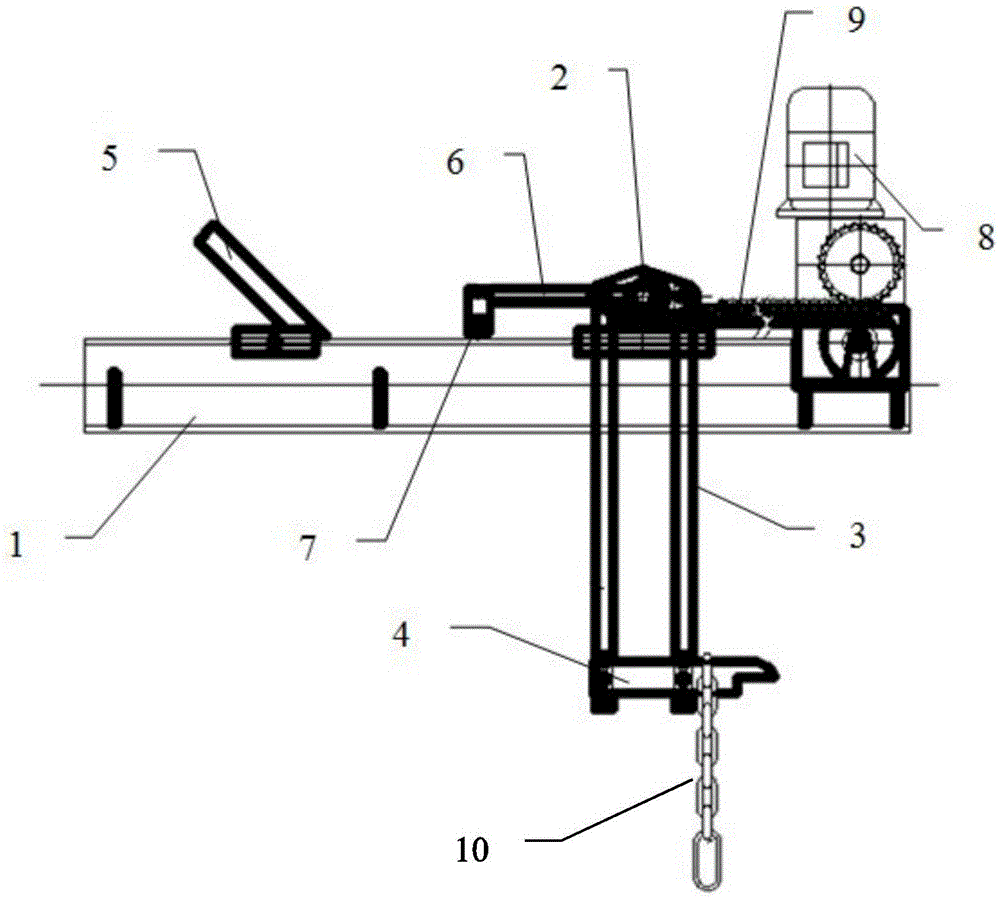

[0021] Such as figure 1 As shown, a kind of bar material automatic packing sleeve chain device described in the present invention comprises:

[0022] The support mechanism includes a bracket and a beam 1, the beam 1 is connected to the bracket and supported by it to a certain height from the ground, the upper part of the beam 1 is provided with a guide rail; in actual use, the bracket is arranged in a U-shaped collection tank Above, the height of the beam 1 from the U-shaped collection tank is adjustable, generally 1-5 meters away from the finished bars to be transferred in the U-shaped collection tank, and deviates from a certain angle directly above the U-shaped collection tank, so as not to affect the finished bars lifting.

[0023] Sliding mechanism, which include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com