Laser cutting mechanism used for clothes cutting equipment

A laser machine base and laser technology, applied in the field of clothing machinery, can solve the problems of slow smoke exhaust speed, fixed area, poor heat dissipation effect, etc., and achieve the effects of high automation, fast smoke exhaust speed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

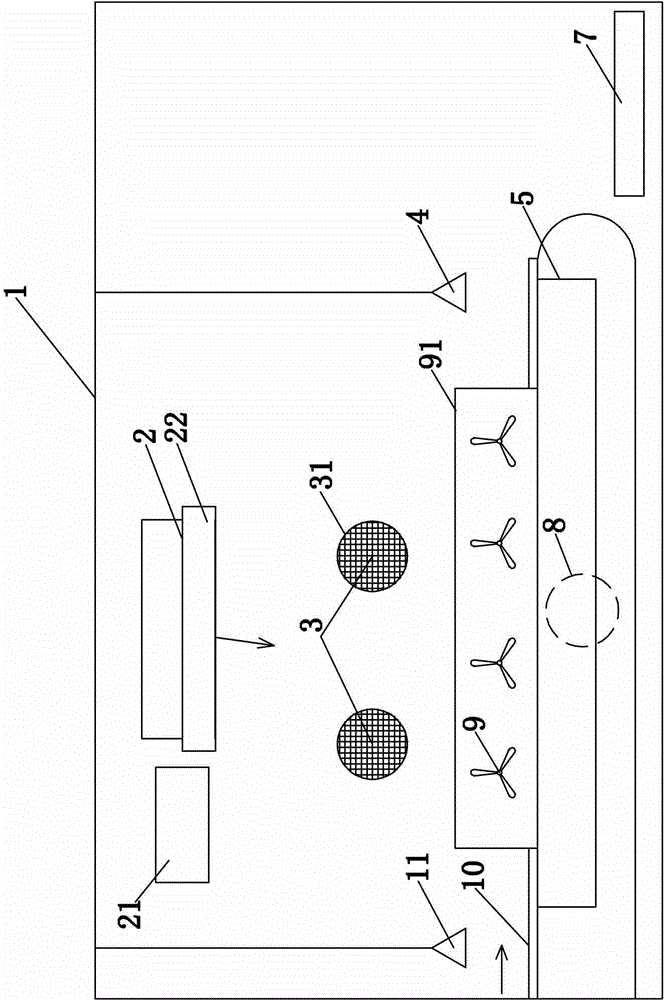

[0016] Example 1, such as figure 1 As shown, a kind of clothing cutting equipment comprises laser cutting mechanism, and this laser cutting mechanism comprises studio 1, laser generator 2 and conveying network chain 10, and the top and bottom of described conveying network chain 10 are respectively provided with smoking port 3 and The air exhaust port 8, the corresponding smoke outlet 3 on the conveying network chain 10 is provided with an air blower 9, the laser frame 22 is arranged on the top of the conveying network chain 10, the laser generator 2 is installed on the laser frame 22, the The feed end of conveying network chain 10 is provided with tailing sensor 11, and the discharging end of described conveying network chain 10 is provided with stop sensor 4, and the below of the discharging end of described conveying network chain 10 is provided with the conveyer belt that is used for picking up and sending cloth. 7. The smoke outlet 3 and the air outlet 8 are connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com