Efficient oilfield reinjection water processing system and method

A technology of oilfield reinjection water and treatment system, which is applied in the field of oilfield reinjection water treatment system, can solve the problems that affect the oilfield production progress, including sewage treatment effect, poor separation effect, long settlement time, etc., to achieve ingenious design, low production cost, and filtration good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

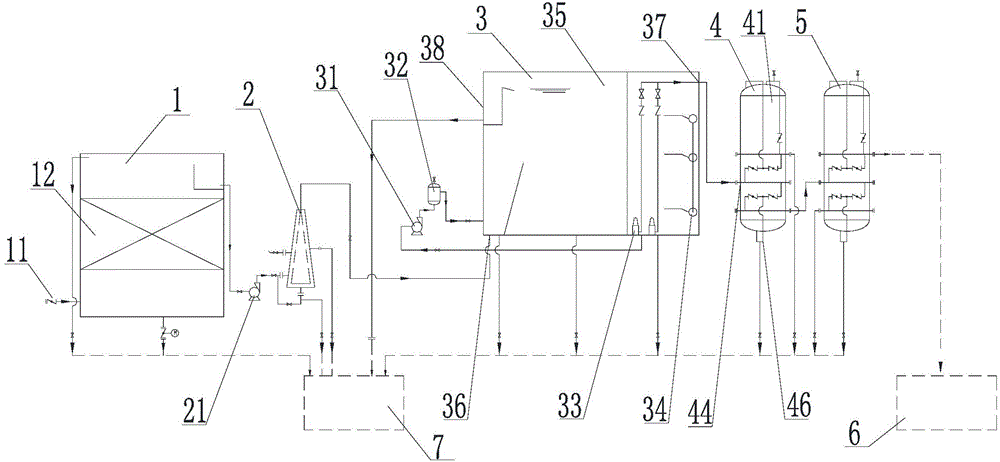

[0036] The present invention as Figure 1-7 As shown, it includes a coalescer 1 communicated with a water inlet valve 11, and the coalescer 1 is sequentially connected to a cyclone 2, an air flotation machine 3, a coarse filter tank 4 and a membrane tank 5, wherein the coalescer 1 , cyclone 2, air flotation machine 3, coarse filter tank 4 and membrane tank 5 are all connected to the dirty oil pool 7, so that the oil stain obtained after each process is processed can be uniformly processed;

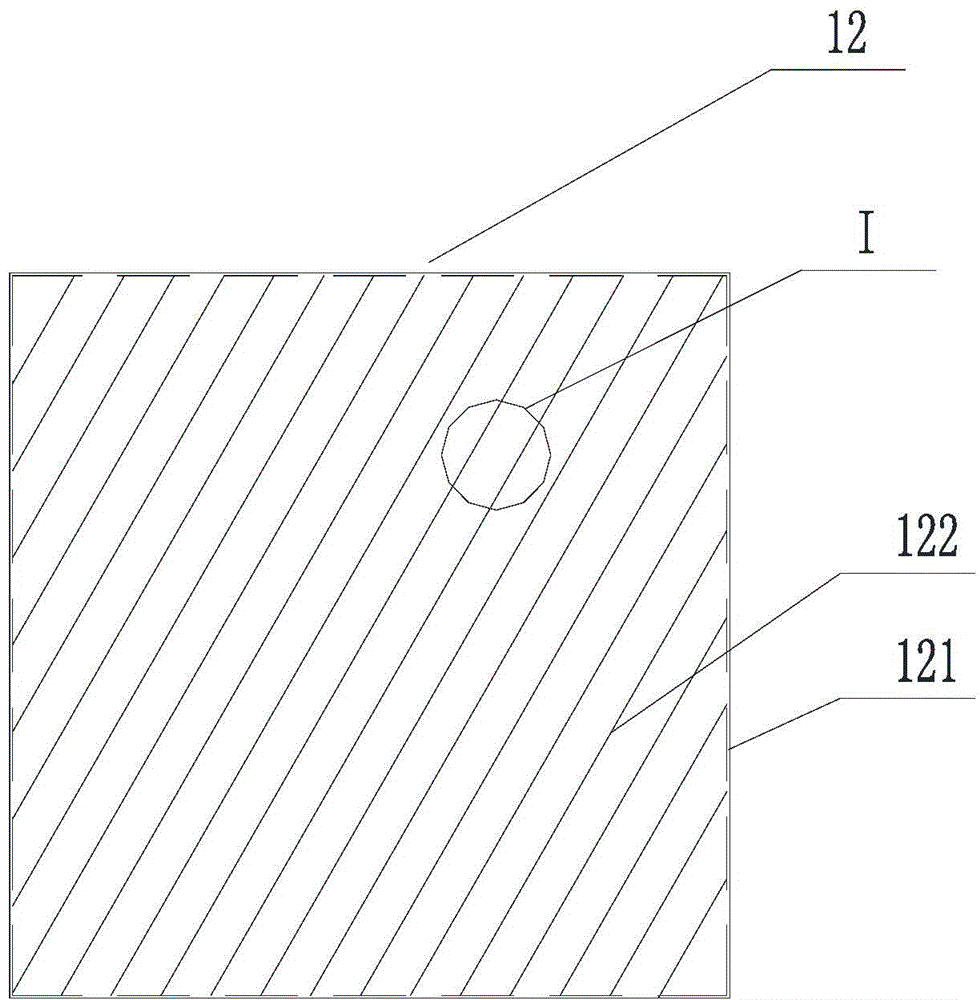

[0037] The coalescer 1 has a water inlet, an oil outlet, a water outlet and a small spacing sloping plate 12, the water inlet is arranged under the small spacing sloping plate 12, and the oil outlet and the water outlet are arranged above the small-pitch sloping plate 12 and respectively located on both sides of the small-pitch sloping plate 12;

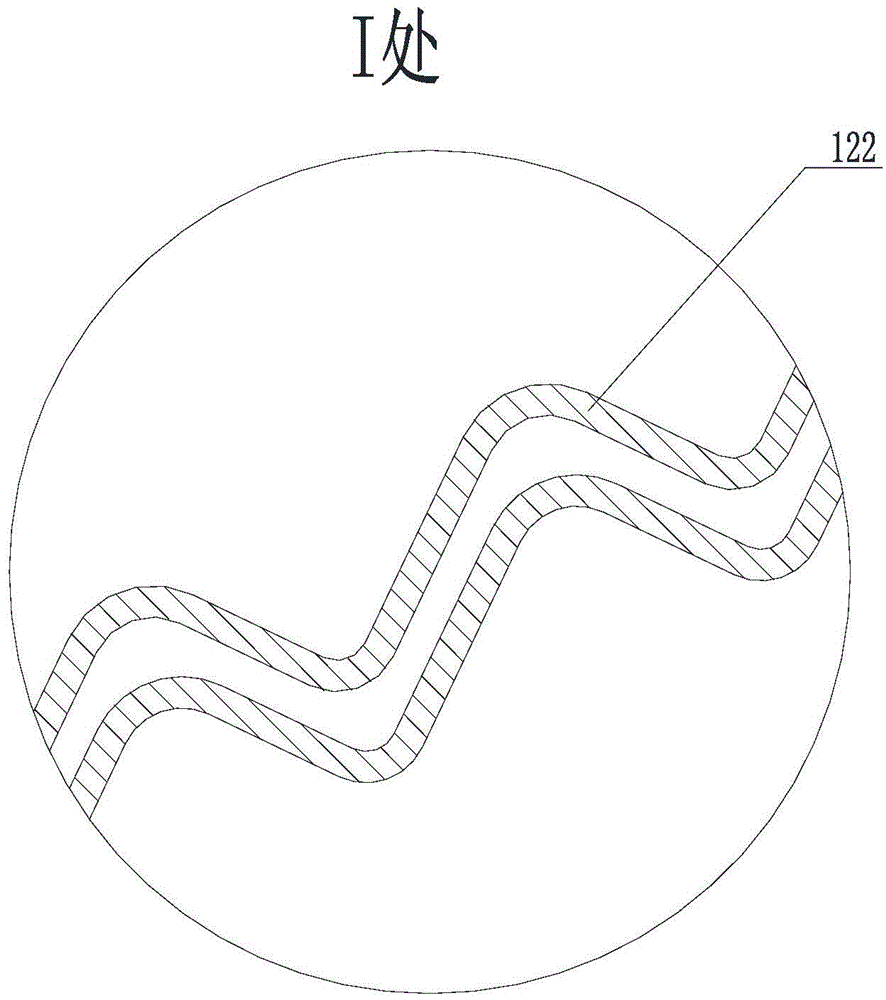

[0038] The small-pitch inclined plate 12 includes a frame 121 and several wave-shaped filter plates 122. The frame 121 is provided with several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com