Special humic acid-urea coated rhizobium fertilizer for soybean and preparation method thereof

A technology of coating root nodules and humic acid, which is applied in urea compound fertilizers, layered/coated fertilizers, applications, etc., to achieve the effects of reducing substances, reducing energy consumption, and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

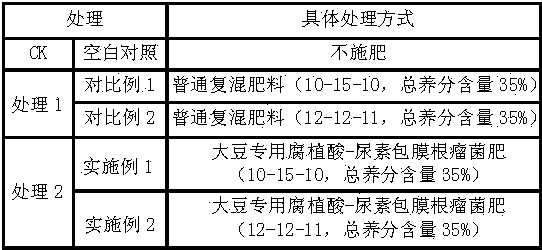

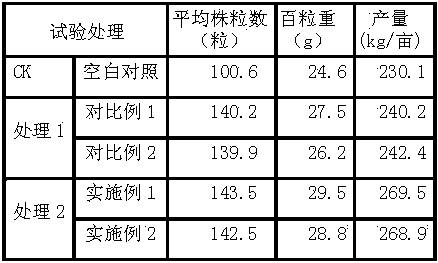

Examples

Embodiment 1

[0048] Humic acid-urea coated rhizobia fertilizer for soybeans of the present invention has the following raw material components, all in parts by weight:

[0049] 100 parts of humic acid-urea coated rhizobia agent composition, 280 parts of humic acid coated urea, 320 parts of double superphosphate, 200 parts of potassium sulfate, and 100 parts of calcium magnesium phosphate fertilizer.

[0050] The prepared soybean-specific humic acid-urea coated rhizobia fertilizer, nitrogen, phosphorus and potassium (N-P 2 o 5 -K 2 O) contents are 10%, 15%, 10% respectively, and the total nutrient is 35%, both are mass percentages.

[0051] Preparation process steps:

[0052] 1. The preparation method of the humic acid-urea coated rhizobia agent composition:

[0053] Adopt liquid ventilation fermentation method to carry out liquid fermentation according to prior art, prepare soybean rhizobia fermented liquid, then obtain rhizobia agent with the described fermented liquid of turf soil ad...

Embodiment 2

[0065] Humic acid-urea coated rhizobia fertilizer for soybeans of the present invention has the following raw material components, all in parts by weight:

[0066] Humic acid-urea coated rhizobia agent composition 120 parts, 5% humic acid coated urea 330 parts, double superphosphate 280 parts, potassium sulfate 220 parts, calcium magnesium phosphate fertilizer 50 parts.

[0067] The preparation process is the same as in Example 1.

[0068] The prepared soybean-specific humic acid-urea coated rhizobia fertilizer contained 12%, 12%, and 11% of nitrogen, phosphorus, and potassium (N-P2O5-K2O) contents, and 35% of total nutrients, both in mass percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com