A linear polyurethane elastomer toughening agent for toughening biological polyester pha and its preparation method and application

A polyurethane elastomer and bio-polyester technology, which is applied in the field of toughened biodegradable polyester, can solve the problems of complicated procedures and lower mechanical properties of polyurethane, and achieve the effects of simple raw materials, improved mechanical properties, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

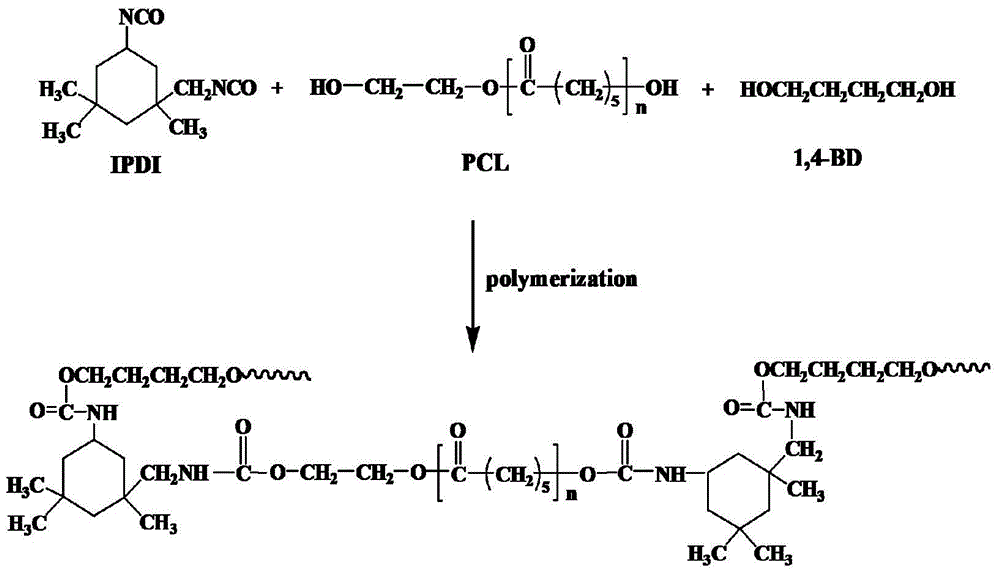

[0045] A method for preparing a linear polyurethane elastomer toughening agent for toughening biopolyester PHA, comprising the following steps: the hard segment content of the linear polyurethane elastomer toughening agent for synthesizing toughened biopolyester PHA is scheduled to be 35%, According to the formula calculation formula, accurately measure 10g of polycaprolactone diol (PCL, molecular weight 1000) after drying, 0.9129g of 1,4-butanediol (BD), and 4.4718g of isophorone diisocyanate (IPDI) Put it into a three-necked flask, use a vacuum method to isolate the air, heat it to 80℃ with oil bath heating, magnetically stir, and react for 2h, then transfer the reaction solution into a mold, put it in a vacuum oven and expand at 125℃. Chaining, deaeration, and after curing for 12 hours, take it out to obtain a linear polyurethane elastomer toughening agent with a hard segment content of 35%; the formula calculation formula is as follows:

[0046] W IPDI / M IPDI =W PCL / M PCL...

Embodiment 2

[0061] A preparation method of a linear polyurethane elastomer toughening agent for toughening biopolyester PHA, comprising the following steps: the hard segment content of the linear polyurethane elastomer toughening agent for synthesizing toughened biopolyester PHA is scheduled to be 45%, According to the formula calculation formula, accurately measure the dried polycaprolactone diol (PCL, molecular weight 2000) 10g, 1,4-butanediol (BD) 1.7198g and isophorone diisocyanate (IPDI) 6.4622g together Put it into a three-necked flask, isolate the air by vacuuming, heat to 60℃ with oil bath heating, stir magnetically, and react for 3h, then transfer the reaction liquid into a mold, put it in a vacuum oven at 100℃ for expansion Chaining, deaeration, and curing for 24h, take it out to obtain a linear polyurethane elastomer toughening agent with a hard segment content of 45%; the formula calculation formula is as follows:

[0062] W IPDI / M IPDI =W PCL / M PCL +W BD / M BD ,

[0063]

...

Embodiment 3

[0078] A method for preparing a linear polyurethane elastomer toughening agent for toughening biopolyester PHA, comprising the following steps: the hard segment content of the linear polyurethane elastomer toughening agent for synthesizing toughened biopolyester PHA is 60%, According to the formula calculation formula, accurately measure 10g of polycaprolactone diol (PCL, molecular weight 3000) after drying, 3.6858g of 1,4-butanediol (BD) and 11.3142g of isophorone diisocyanate (IPDI) Put it into a three-necked flask and use N 2 Isolate the air, heat to 70℃ with oil bath heating method, magnetically stir, and react for 2.5h, then transfer the reaction liquid into the mold, put it in a vacuum oven at 110℃ for chain extension and degassing, after curing for 18h Take it out to obtain a linear polyurethane elastomer toughening agent with a hard segment content of 60%; the formula calculation formula is as follows:

[0079] W IPDI / M IPDI =W PCL / M PCL +W BD / M BD ,

[0080]

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

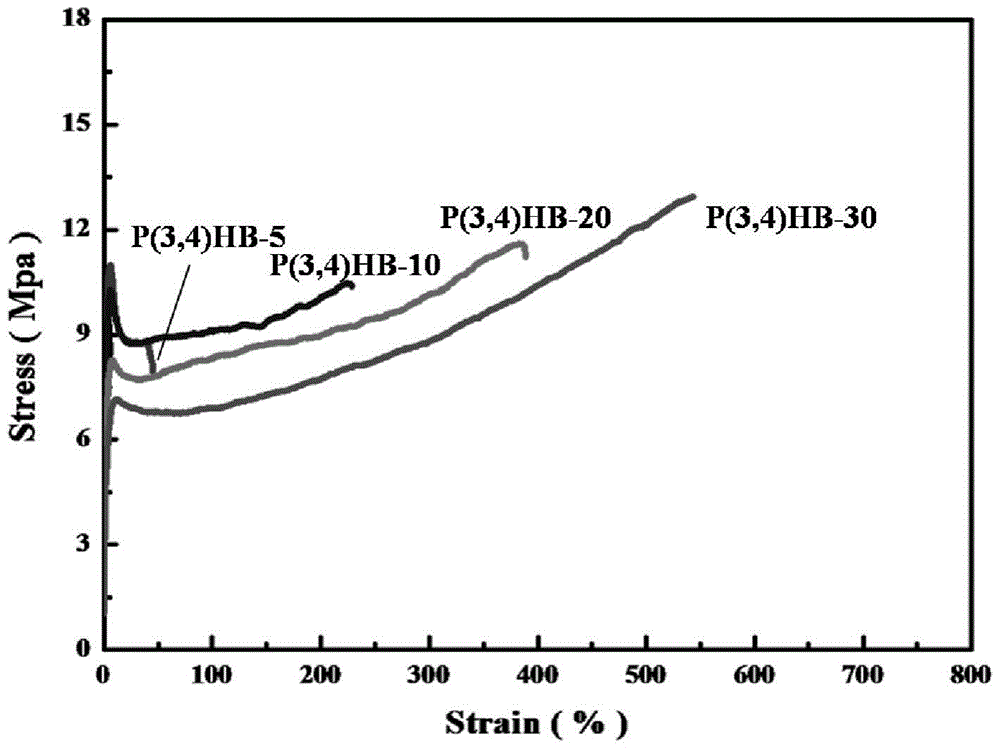

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com