Patents

Literature

43results about How to "Has a toughening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High wear resistance surfacing alloy material containing multiphase metal ceramics

ActiveCN101879670AImprove performanceInhibit growthWelding/cutting media/materialsSoldering mediaHigh carbonRare earth

The invention relates to a high wear resistance surfacing alloy material containing multiphase metal ceramics and belongs to the technical field of the material. The high wear resistance surfacing alloy material comprises the following ingredients in percentage by weight: 25 to 50 percent of ferrochrome, 1 to 10 percent of ferrotitanium, 1 to 10 percent of ferrovanadium, 0.1 to 5 percent of rare earth material, 1 to 7 percent of ferroboron, 0.4 to 8 percent of ferromolybdenum, 0.5 to 5 percent of aluminium powder, 0.4 to 7 percent of ferronickel, 0.1 to 10 percent of powder material, 8 to 15 percent of sodium potassium silicate, 0.1 to 5 percent of carbon black and the balance of ferrum, wherein the granularity is between 70 and 140 meshes. When the high wear resistance surfacing alloy material containing the multiphase metal ceramics of the invention is adopted to carry out carbon arc surfacing or plasma surfacing, the operation method is simple and the cost is low. Compared with a manual wear-resistance surfacing electrode, the high wear resistance surfacing alloy material is easy to obtain a surfacing layer with high carbon content, high hardness and high wear resistance and has the advantages of firm combination of hard phases and a matrix, high performance of resisting abrasive wear and wide application range.

Owner:LIAONING TECHNICAL UNIVERSITY +1

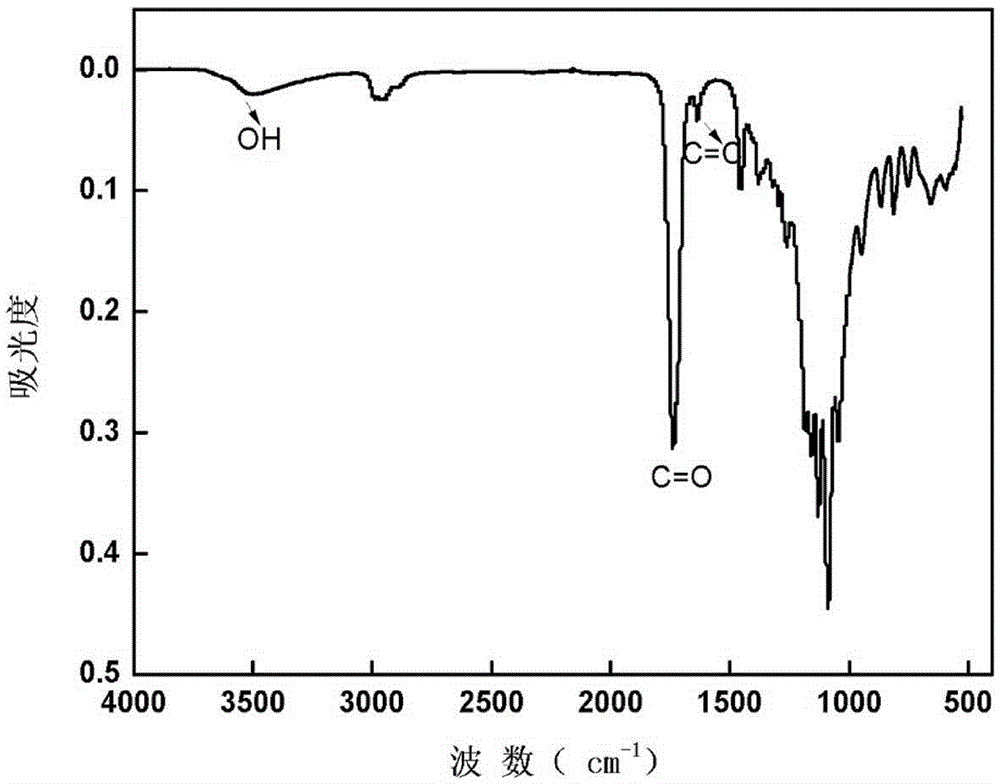

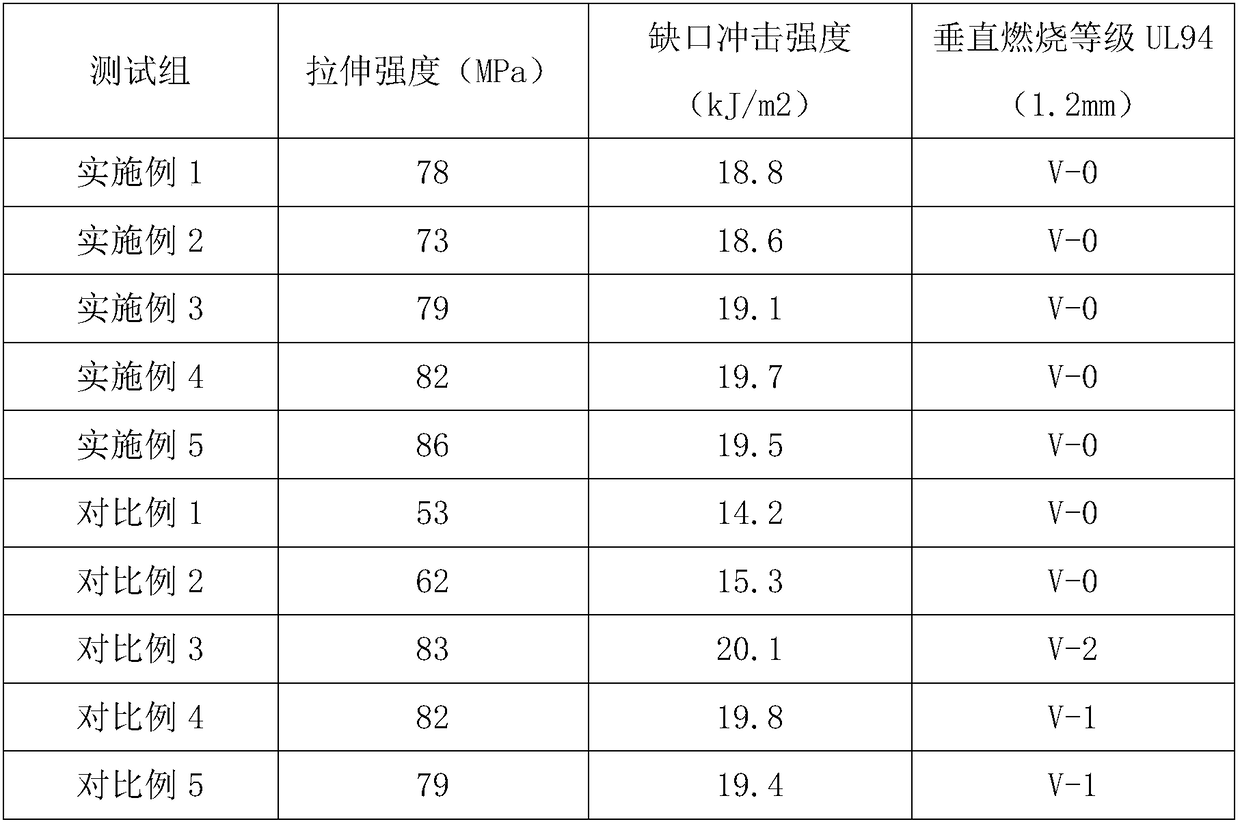

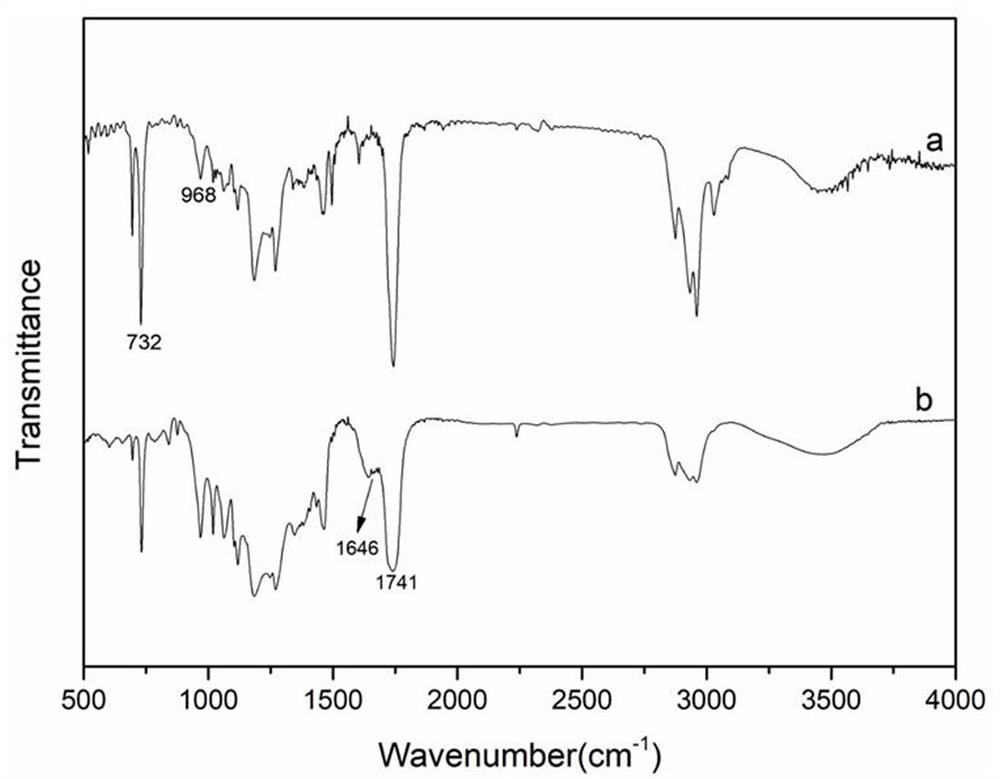

Method for preparing branching type water-based epoxy curing agent

The invention discloses a branched waterborne epoxy curing agent and a preparation method thereof: monoepoxy compound is firstly used for carrying out the end-blocking reaction of one end of aliphatic polyamine or aromatic polyamine or the aliphatic polyamine or the aromatic polyamine which undergoes the chain extension by polyether alcohol diglycidyl ether or polyether epoxy resin, and primary amine hydrogen at the other end of the polyamine is simultaneously maintained. Then, novolac epoxy resin or novolac epoxy resin solution is dipped in the solution of the intermediate product of the reaction for carrying out the branching reaction; after that, distilled water solution of monoatomic organic acid is dripped in adduct after the branching for carrying out the salt forming dispersion reaction; and the branched waterborne epoxy curing agent is finally prepared. When in use of the branched waterborne epoxy curing agent of the invention and waterborne epoxy resin component, the branched waterborne epoxy curing agent has the advantages of low viscosity and long application period; and the cured product can overcome the shortcoming of brittle performance of the ordinary epoxy resin material on the premise of keeping good heat resistance.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

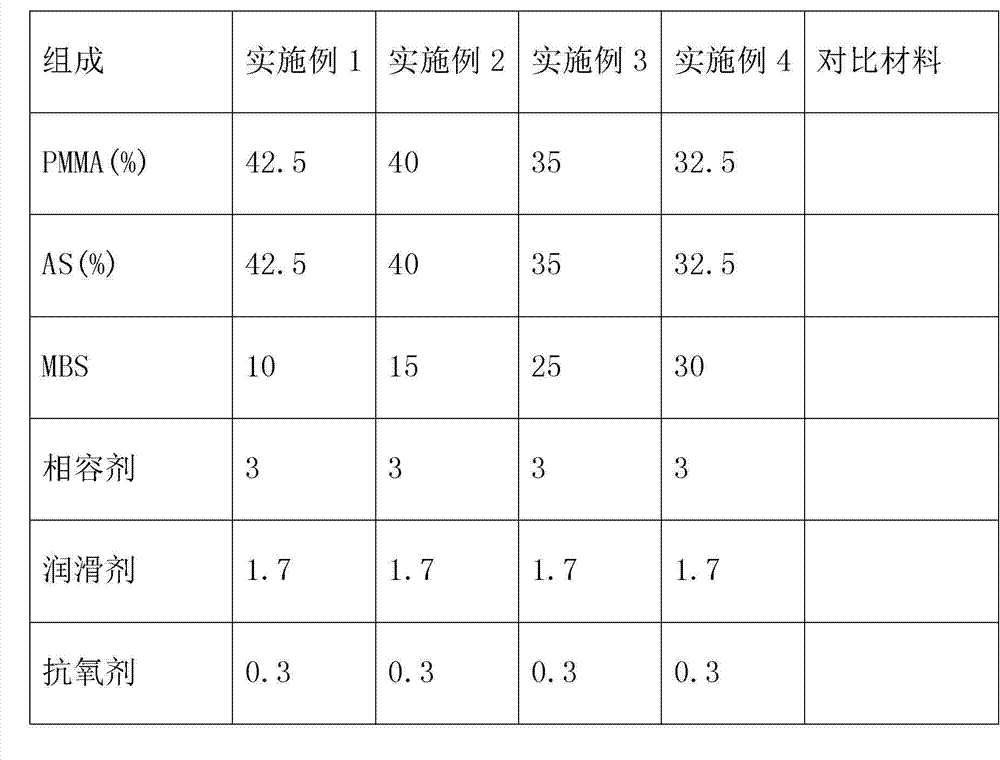

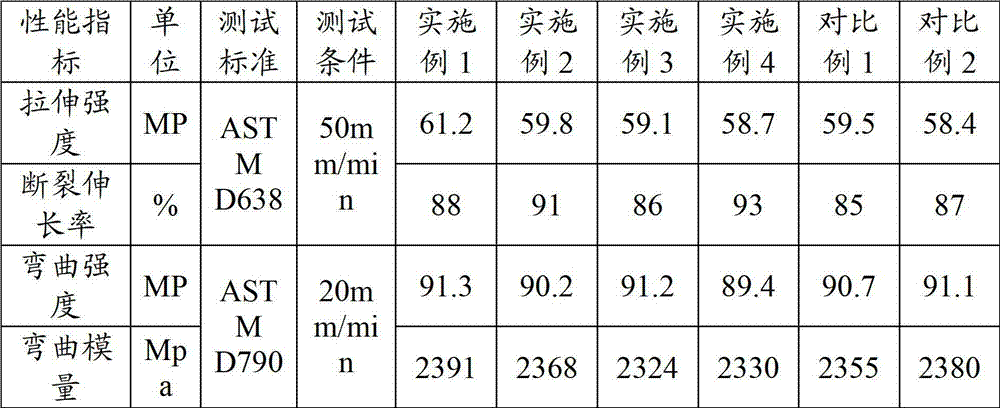

Spraying-free high-transparent high-glossy acrylonitrile butadiene styrene (ABS) material and preparation method thereof

ActiveCN102766306AHigh impact strengthImprove physical and mechanical propertiesAntioxidantPolymethyl methacrylate

The invention discloses a spraying-free high-transparent high-glossy acrylonitrile butadiene styrene (ABS) alloy material and a preparation method thereof. The ABS alloy material comprises, by weight, 30-45% of polymethyl methacrylate (PMMA), 30-45% of acrylonitrile styrene (AS), 10-30% of flexibilizer, 1-5% of compatilizer, 0.3% of antioxidant and 0.7-2% of lubricant. The material has good transparency and high impact strength, modulus, surface glossy and surface scraping resistance, retains good processability and toughness of the ABS alloy material, and simultaneously has the advantages of good weather resistance, surface hardness, chemical resistance and glossy and the like of the PMMA and AS resin. The spraying-free high-transparent high-glossy ABS alloy material and the preparation method expand an application range of the ABS material in transparent materials. The preparation method includes the following steps: mixing raw materials according to the ratio, adding mixed resin into a plastic extruding machine, controlling the temperature to be 190-225 DEG C and granulating to obtain the spraying-free high glossy transparent ABS alloy material.

Owner:LONGJAR SHANGHAI IND

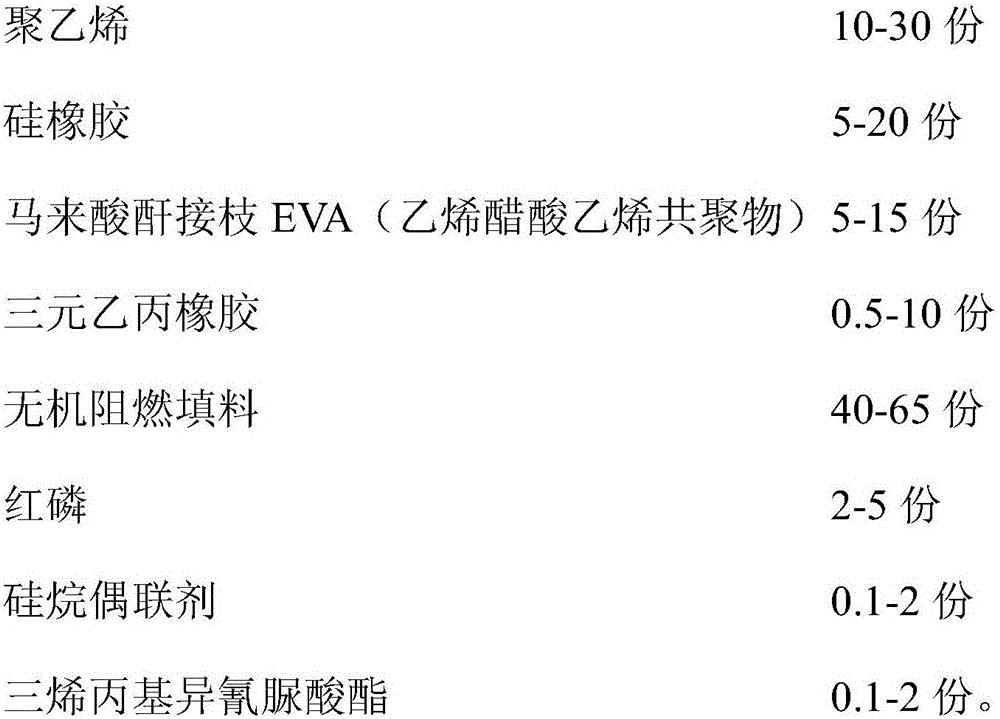

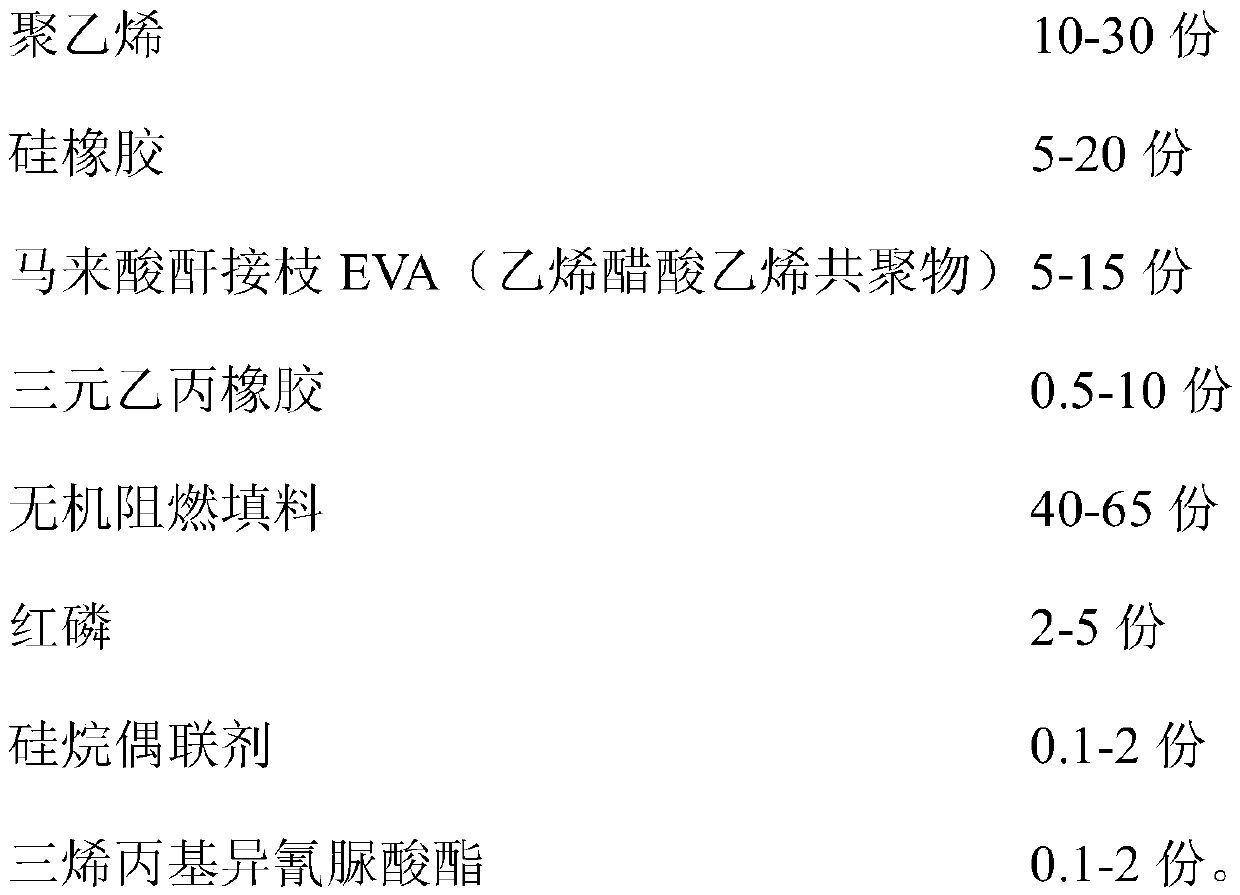

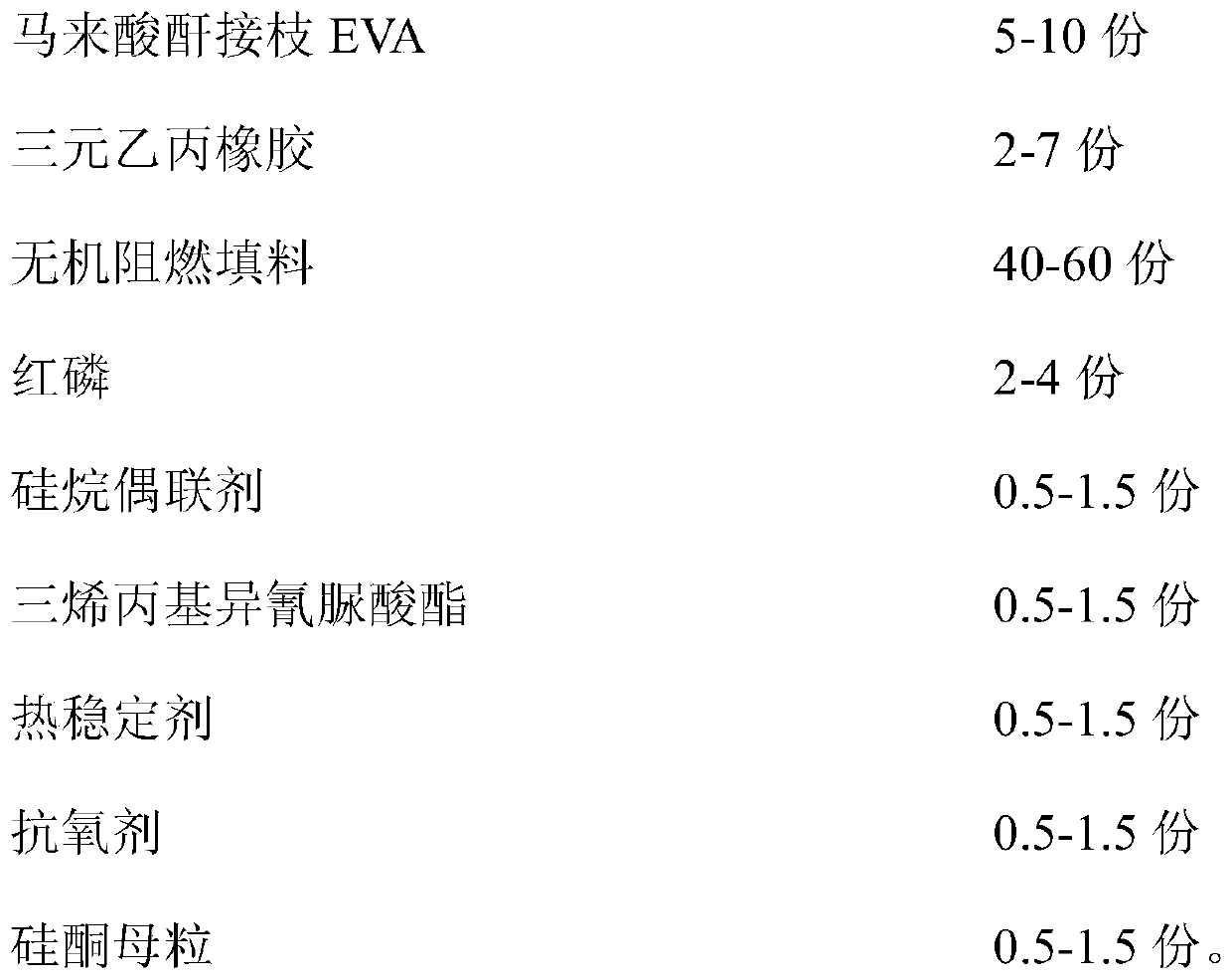

Cable material, and preparation method and application thereof

ActiveCN106380861ASuitable processing performanceGood compatibilityInsulated cablesInsulated conductorsPolymer sciencePliability

The invention provides a cable material, and a preparation method and application thereof. The cable material is prepared from the following raw materials in parts by weight: 10-30 parts of polyethylene, 5-20 parts of silicone rubber, 5-15 parts of maleic anhydride graft EVA (ethylene-vinyl acetate), 0.5-10 parts of ethylene propylene diene monomer rubber, 40-65 parts of flame retardant, 2-5 parts of red phosphorus, 0.1-2 parts of silane coupling agent and 0.1-2 parts of triallyl isocyanurate. The preparation method comprises the following steps: banburying, extrusion and irradiation crosslinking. The cable material provided by the invention has the advantages of high flexibility, favorable insulativity, favorable flame retardancy, favorable oil resistance and favorable cold resistance, and is applicable to automobile wire insulating materials.

Owner:JIANGSU DASHENG POLYMER

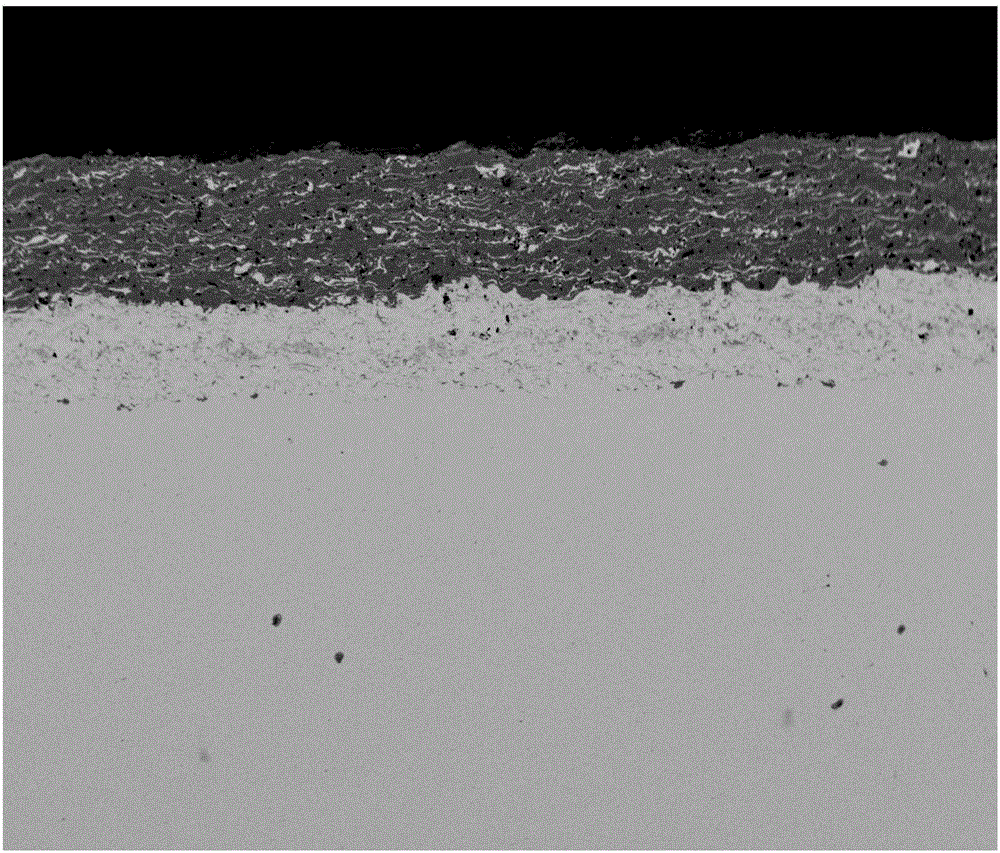

Coating for improving abrasion resistance of ship gas turbine compressor drum and preparation method of coating

InactiveCN106756713ASimple and practicalHas a toughening effectMolten spray coatingFiberCeramic composite

The invention provides a coating for improving abrasion resistance of a ship gas turbine compressor drum and a preparation method of the coating. A gas turbine compressor drum alloy matrix is pretreated; ceramic fiber is pretreated, then, 18%-80% of YSZ powder, 18%-80% of Al2O3 powder and 2%-20% of the ceramic fiber are mixed proportionally by mass to obtain a mixture, and the mixture is subjected to ball milling treatment, so that ceramic composite powder is obtained; a bonding layer is sprayed to the surface of the gas turbine compressor drum alloy matrix through a plasma spraying method; and a ceramic composite working layer continues to be sprayed to the bonding layer through plasma spraying. According to the coating and the preparation method of the coating, the problem that a ceramic coating is high in brittleness and poor in toughness is solved by adding the ceramic short fiber, fiber tightening is achieved in the plasma ceramic coating, the rupture work of the composite coating in the friction and abrasion processes is increased, brittle lamellar type peeling of the ceramic coating is relieved, and the purpose of improving the abrasion resistance is achieved.

Owner:HARBIN ENG UNIV

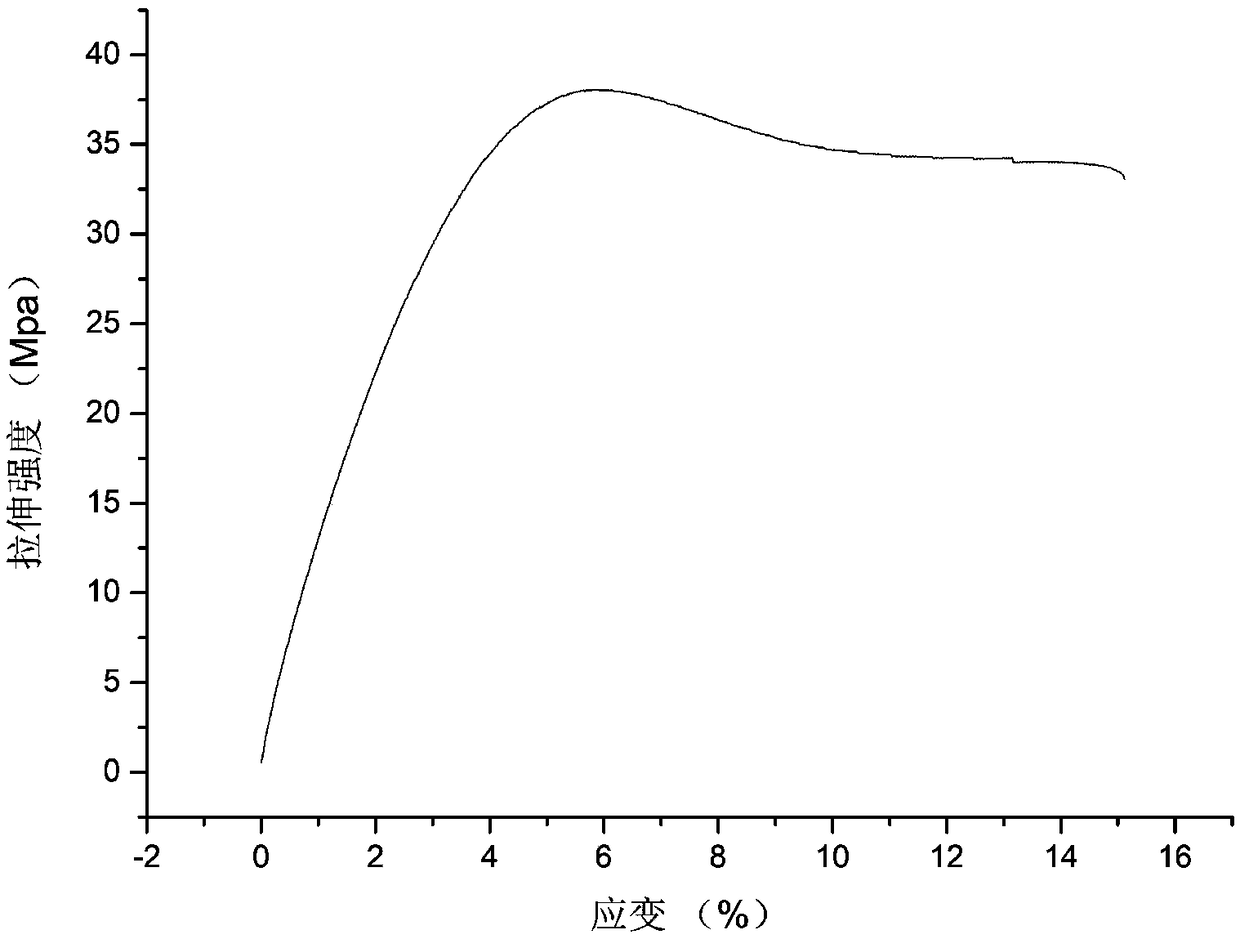

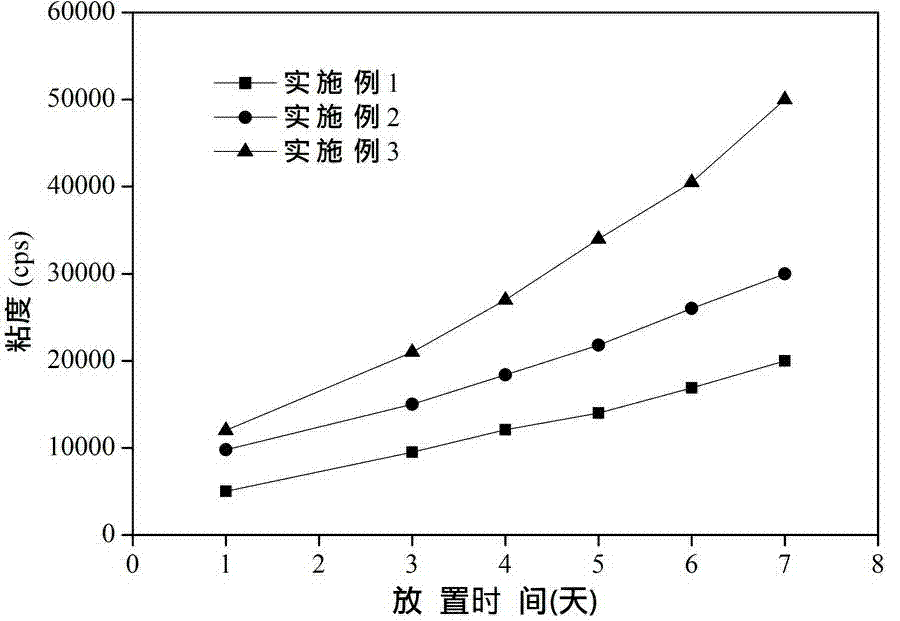

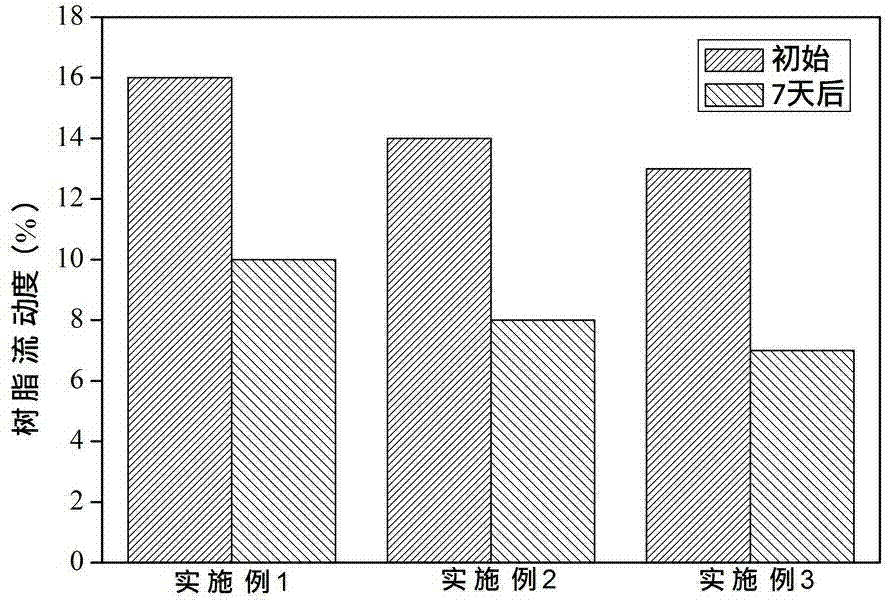

Preparation method of epoxy resin system for prepregs, and prepreg preparation method

The present invention provides a preparation method of an epoxy resin system for prepregs. The preparation method comprises: stirring an epoxy resin matrix at a temperature of 50-100 DEG C to form a component A; mixing a room temperature reactive curing agent and a latent curing agent to form a component B; and carrying out a mixing reaction on the component A and the component B according to a mass ratio of 100:10-20 to obtain the epoxy resin system for prepregs. The present invention further provides a prepreg preparation method. According to the present invention, when the epoxy resin system is used for preparing the glue forming film, the viscosity of the epoxy resin system is low so as to ensure the infiltration enhancement of the fibers or each fiber of the fabric, and due to the addition of the room temperature reactive curing agent having the flexible segment, the epoxy resin system can continuously react during the subsequent placing so as to improve the viscosity of the epoxy resin system and reduce the resin fluidity of the prepreg, wherein the flexible segment can toughen the composite material.

Owner:CHINA PETROLEUM & CHEM CORP +1

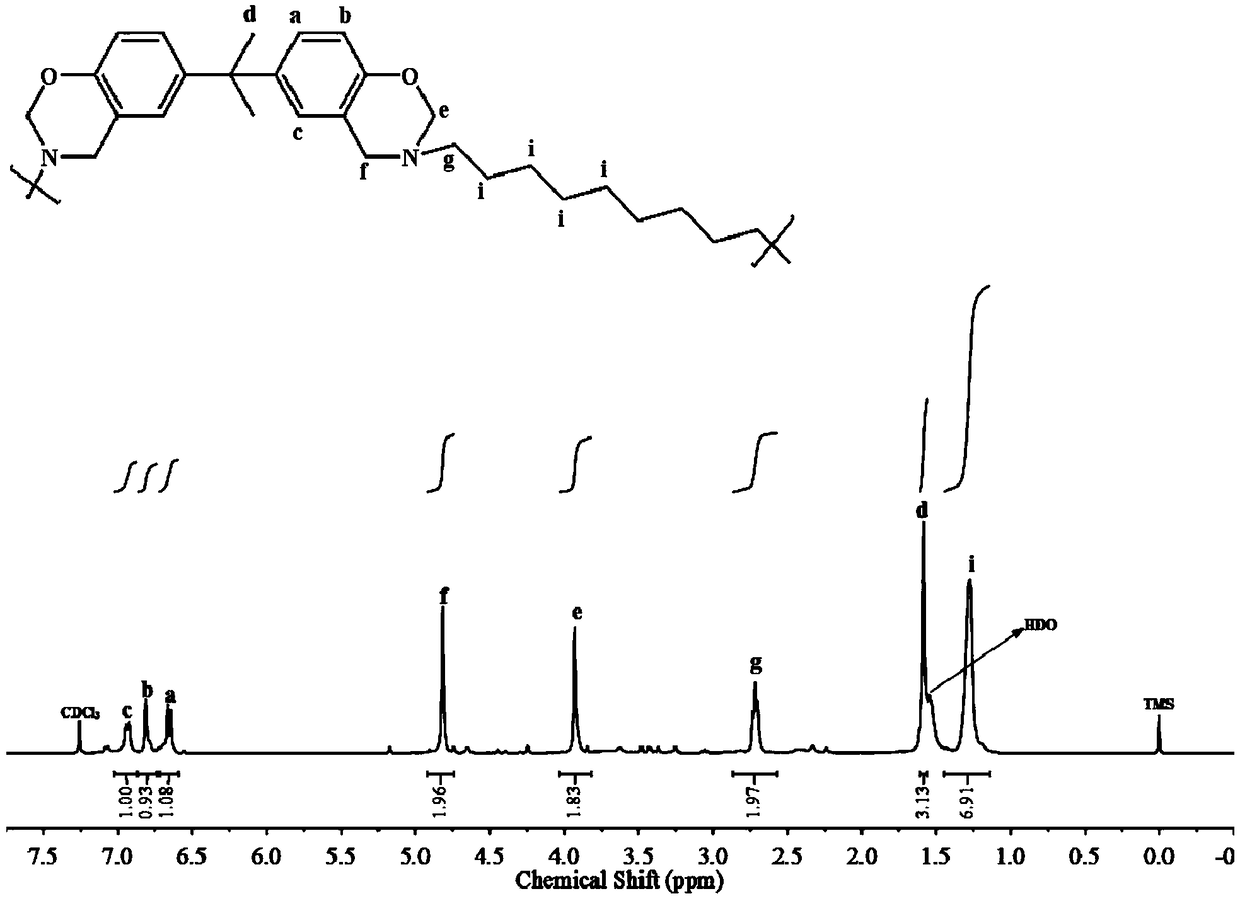

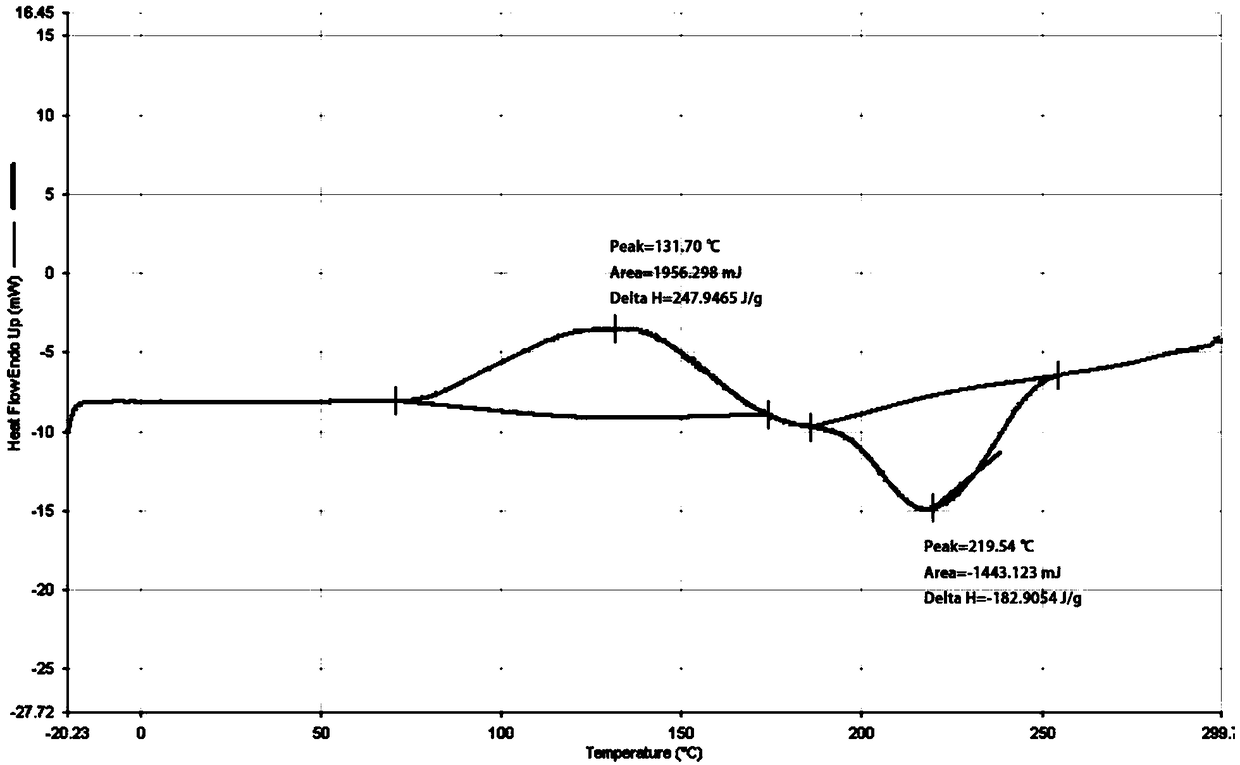

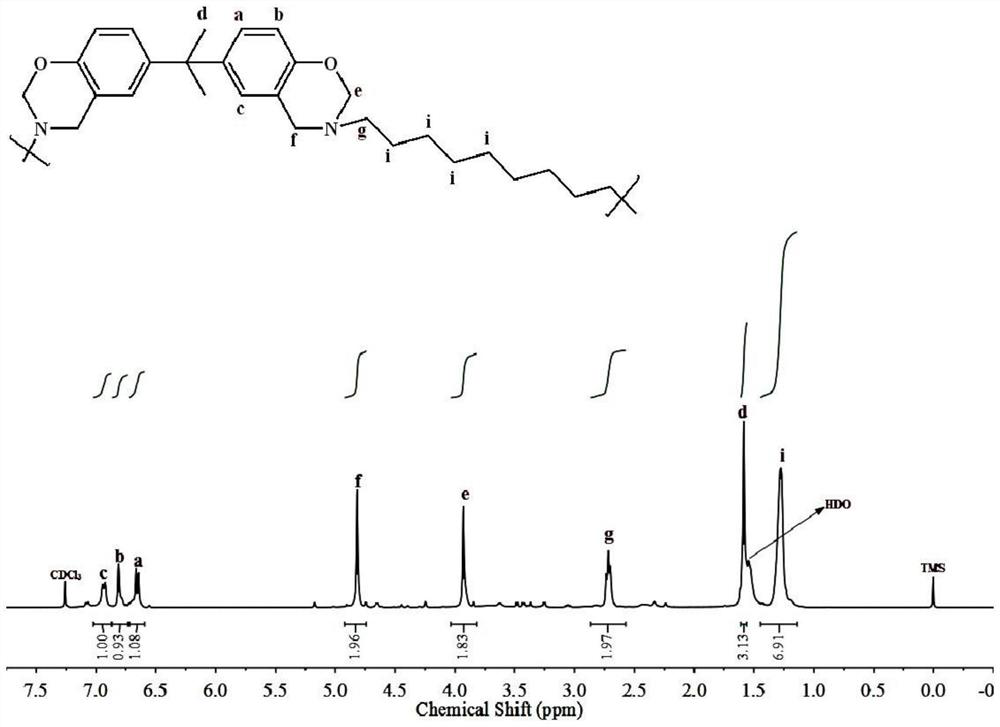

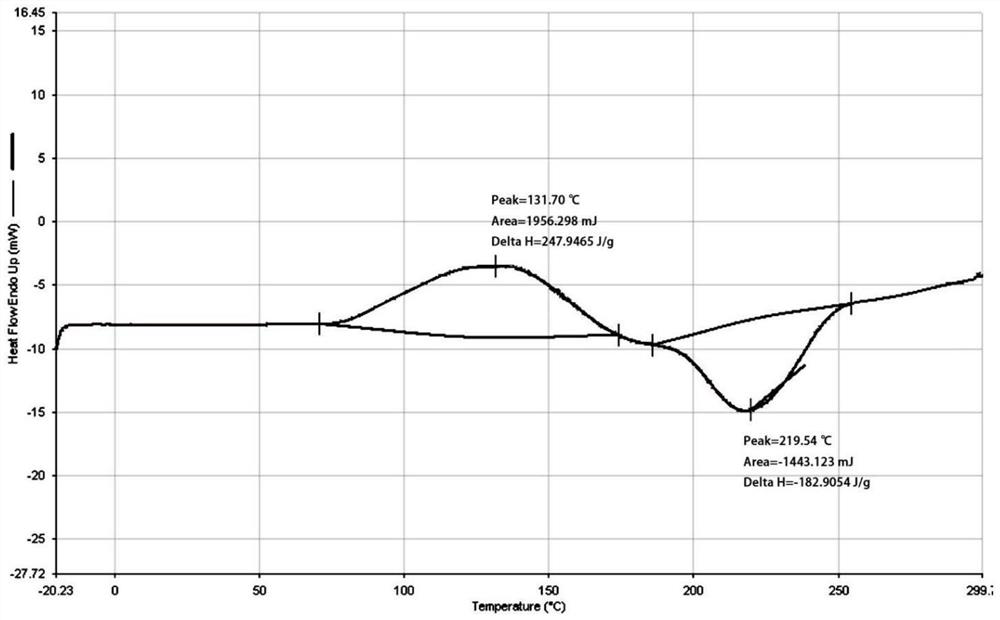

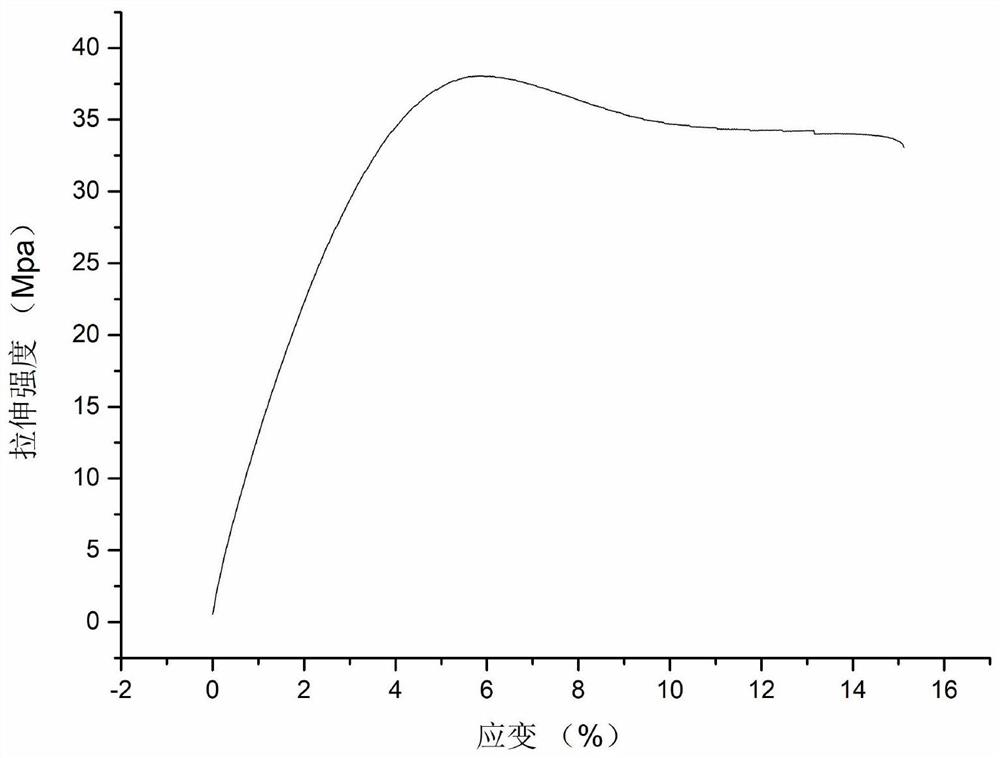

Self-toughened benzoxazine thermosetting resin and method for preparing same

The invention provides self-toughened benzoxazine thermosetting resin with structures shown as a formula I. The self-toughened benzoxazine thermosetting resin has the advantages that long alkyl chainsare led into chemical structures of benzoxazine, accordingly, toughening effects can be realized, and the self-toughened benzoxazine thermosetting resin has self-toughened characteristics; the long alkyl chains are led into the chemical structures of the benzoxazine in chemical bond forms, and accordingly the problem that the traditional added toughening agents are dissolved out due to poor compatibility can be effectively solved; the long alkyl chains are added into the self-toughened benzoxazine thermosetting resin, the concentration of oxazine rings can be diluted, and accordingly the curing temperature of the self-toughened benzoxazine thermosetting resin can be obviously lowered; the long alkyl chains are led into the structures of the benzoxazine, good internal plasticization effects can be realized, and accordingly the toughness of self-toughened benzoxazine thermosetting resin cured substances can be greatly improved.

Owner:GUIZHOU INST OF TECH +1

Method for preparing prepreg through regulating and controlling viscosity of epoxy resin system and fluidity of prepreg by chemorheology

The invention provides a method for preparing a prepreg through regulating and controlling viscosity of an epoxy resin system and fluidity of the prepreg by chemorheology. According to the method, a mixed curing agent of a room temperature reactive curing agent and a latent curing agent is adopted, and the epoxy resin system with low viscosity for the prepreg is prepared through the initial chemical reaction of the mixed curing agent and the epoxy resin component; adhesive films are prepared from the resin system by a film forming machine, then the adhesive films and reinforced fibers or fabric are compounded through a compound machine, and the prepreg with excellent dipping characteristic is prepared; the prepreg is placed at room temperature so that the fluidity of the prepreg is regulated and controlled, and the prepreg with good technological operation property and joint property is obtained. Compared with traditional manufacture technique of the prepreg, the method can guarantee that the reinforced fibers can be dipped in the epoxy resin with low viscosity, and every single monofilament can be dipped completely; and through following-up chemical reaction at room temperature, the grease fluidity of the prepared prepreg can be lowered, so that the technological requirements of composite material forming can be met.

Owner:BEIJING UNIV OF CHEM TECH

High-light-shielding high-impact-resistance PC/PBT alloy material and preparation method thereof

InactiveCN109880335AImprove mechanical propertiesGood shading effectPolytetramethylene terephthalateOptical property

The invention provides a high-light-shielding high-impact-resistance PC / PBT alloy material and a preparation method thereof. The alloy material comprises the following components in parts by weight: 30-40 parts of polycarbonate, 15-25 parts of polybutylene terephthalate, 10-15 parts of an inorganic filler, 5-10 parts of a compatilizer, 1-5 parts of an ester exchange inhibitor, 1-5 parts of an antioxidant, 1-5 parts of a light stabilizer and 1-5 parts of a coupling agent. The alloy material has the advantages of high light shielding property, high toughness, good solvent resistance, dimensionalstability, high strength, easiness in forming and the like, and the material cost is reduced on the premise that the optical property and the notch impact strength are greatly improved.

Owner:太仓市华鼎塑料有限公司

Insulating water-based epoxy self-adhesive paint and preparation method thereof

ActiveCN112724793AImprove high temperature resistanceLight weightFireproof paintsAnti-corrosive paintsPolymer scienceFirming agent

The invention relates to the technical field of epoxy self-adhesive paint, in particular to insulating waterborne epoxy self-adhesive paint and a preparation method thereof. The insulating water-based epoxy self-adhesive paint is prepared from the following raw materials: epoxy resin, a cosolvent, spherical organic silicon resin, a water-based coupling agent, an emulsifier, water, a latent curing agent, a leveling agent, a wetting agent and an antifoaming agent. The self-adhesive paint has the excellent effects of high temperature resistance, smoothness, low specific gravity, water resistance, salt spray resistance and insulation. The preparation method comprises the following steps: adding the spherical organic silicon resin and the coupling agent into water, heating, and carrying out heat preservation reaction to obtain a modifier; dissolving epoxy resin in a cosolvent, heating, adding the modifier and the emulsifier, uniformly stirring, and dropwise adding residual water until the viscosity is reduced in a cliff manner; finally, adding a latent curing agent, a leveling agent, a wetting agent and an antifoaming agent, keeping the temperature, and performing uniform dispersing to obtain a finished product. The preparation method is simple to operate and convenient for batch production.

Owner:ZHEJIANG RONGTAI TECH ENTERPRISE

Conducive polyacrylonitrile fiber and preparation method thereof

InactiveCN108588886AImprove conductivityImprove surface activityElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentAcrylonitrileDibenzoyl Peroxide

The invention discloses conducive polyacrylonitrile fiber, which is prepared from the following raw materials in parts by weight: 110 to 130 parts of acrylonitrile, 4 to 6 parts of dibenzoyl peroxide,2 to 3 parts of acetylene black, 17 to 20 parts of alkenyl succinic anhydride, 0.1 to 0.2 part of polysorbate, 0.7 to 1 part of calcium stearate, 0.4 to 1 part of diphenyl imidazoline, 3 to 4 parts of pentaerythritol and 0.5 to 0.6 part of ammonium persulfate. The acrylonitrile is used as monomers to be polymerized under the effect of initiators, so that the carbon black doped polyacrylonitrile is obtained. The conduction performance of the finished product fiber can be effectively improved; the toughening effect is also achieved.

Owner:芜湖天科生物科技有限公司

PC composite material, as well as preparation method and application thereof

The invention is applicable in the field of engineering plastics and provides a PC composite material, as well as a preparation method and application thereof. The PC composite material comprises polycarbonate and PMMA-PBA core-shell copolymer. According to the PC composite material provided by the invention, by virtue of the PMMA-PBA core-shell copolymer as light dispersion agent, the light dispersion effect and the toughness are improved. The PC composite material provided by the invention has a simple preparation method, is simple to operate, has a low cost and is very suitable for industrial production. Owing to the PMMA-PBA core-shell copolymer as light dispersion agent, the prepared PC composite material is excellent in light dispersion effect and toughening effect.

Owner:ANHUI KEJU NEW MATERIALS

Manufacture method of writing brush

The invention belongs to the field of writing brush processing, and in particular relates to a production method of a writing brush, comprising the following steps: 1) modifying nylon hair to obtain modified nylon hair; 2) washing rabbit hair, duck hair and pig hair with soap respectively Soak in water for 50-75 minutes, then soak in starch solution for 20-35 minutes, take it out and soak in acetic acid for 3-5 minutes; 3) Use the treated rabbit hair, duck hair, pig hair and modified nylon hair The combing machine mixes evenly in proportion, and picks a bunch of the mixed pen core hair when making the pen core, spreads the bunch of hair on a flat plate, after grooming, and then rolls up from one end to form a conical pen tip. Put the tied nib on the pen tube and connect it with glue. Through the improved nylon hair technology, this brush is more elastic, more durable, and has a long storage time; coupled with the elasticity of animal hair itself, this brush is vigorous and powerful in use, soft and hard, and suitable for a wide range of people.

Owner:广安市广安区长乐小学校

Modified phenolic resin material and preparation method thereof

InactiveCN111454536ALow content of free formaldehydeIncrease the relative molecular massFiberPolymer science

The invention provides a modified phenolic resin material and a preparation method thereof, and relates to the technical field of polymer materials. The modified phenolic resin material is prepared from the following raw materials in parts by weight: 100 parts of cashew nut shell oil modified phenolic resin, 10 to 20 parts of hydroxyl-terminated liquid polybutadiene rubber, 3 to 8 parts of SiO2 coated carbon fibers, 1 to 3 parts of an inorganic filler, 0.5 to 0.8 part of a silane coupling agent, 5 to 9 parts of a foaming agent, 0.3 to 0.6 part of an antioxidant and 3 to 6 parts of a curing agent. The modified phenolic resin material is high in toughness, high in strength, excellent in heat resistance and flame retardance, good in heat insulation effect and extremely low in free formaldehyde content.

Owner:郭芳芳

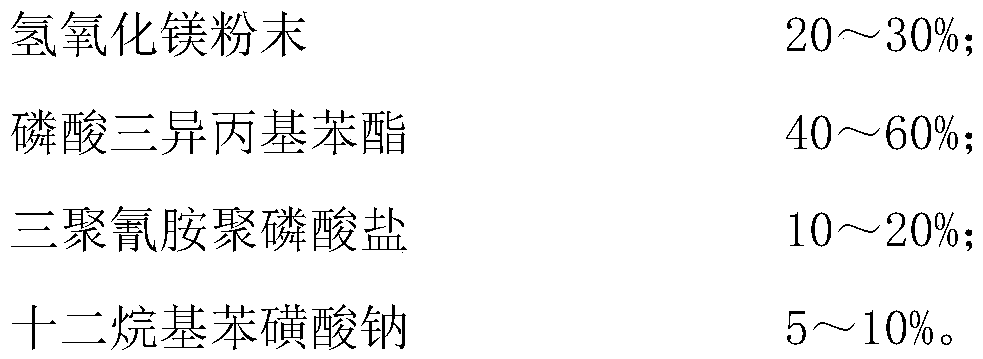

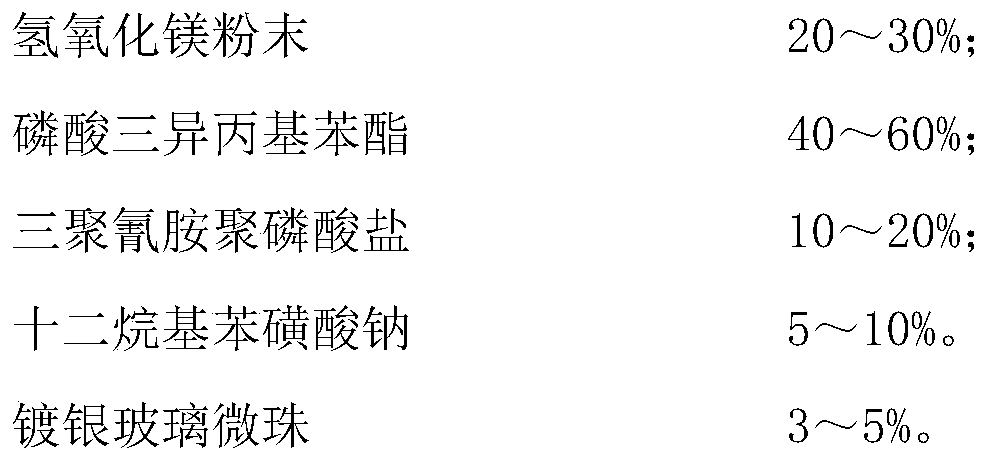

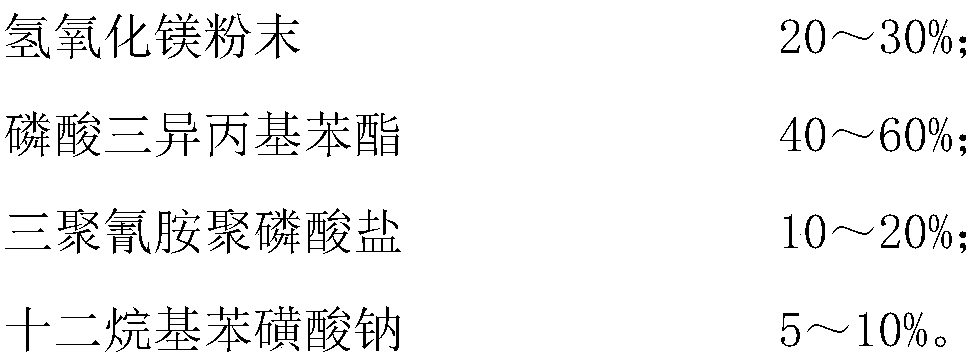

Production process for flame-retardant color masterbatches

InactiveCN110938277AImprove flame retardant performanceHas a toughening effectMasterbatchPolymer science

The invention discloses a production process for flame-retardant color masterbatches, and relates to the technical field of color masterbatches. The production process comprises the following processsteps: S1, batching: a step of weighing the following raw materials in parts by weight: 40-60 parts of carrier resin, 10-20 parts of a pigment and 1-3 parts of a dispersing agent, wherein the carrierresin comprises, in percentages by weight, 50-60% of ABS resin and 40-50% of a flame-retardant filling material; S2, mixing: a step of crushing the carrier resin, then adding the dispersing agent, carrying out stirring for 40-50 min, adding the pigment, and carrying out stirring for 30-40 min; and S3, extrusion: a step of adding the raw materials mixed in the step S2 into a twin-screw extruder, and carrying out extrusion and granulation. The flame-retardant color masterbatch product is obtained by adopting the above-mentioned three steps. The preparation method provided by the invention has the advantage of improving the flame retardance of the color masterbatches.

Owner:绍兴市上虞鸿越塑业有限公司

Special heat-resisting and flame-retarding epoxy resin adhesive for stone material

InactiveCN106753127AImprove flame retardant performanceImprove heat resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyHexagonal boron nitride

The invention discloses a special heat-resisting and flame-retarding epoxy resin adhesive for a stone material. The special heat-resisting and flame-retarding epoxy resin adhesive is prepared from the following raw materials in parts by weight: 70 to 85 parts of modified epoxy resin, 5 to 20 parts of polyamide acid, 3 to 15 parts of 2,6-dimethyl-1,4-phenylate, 5 to 12 parts of an acrylonitrile-styrene-acrylate copolymer, 5 to 20 parts of polyethersulfone, 2 to 10 parts of hydroxyl-terminated liquid nitrile butadiene rubber, 2 to 12 parts of dicyandiamide, 3 to 12 parts of benzoxazine, 2 to 10 parts of linear phenol-formaldehyde resin, 1 to 5 parts of liquid methyl tetrahydrophthalic anhydride, 1 to 5 parts of a curing accelerant, 2 to 10 parts of nano aluminum hydroxide, 2 to 5 parts of silicon micro-powder, 5 to 15 parts of ferroferric oxide, 2 to 8 parts of nano titanium dioxide and 2 to 11 parts of hexagonal boron nitride. The special heat-resisting and flame-retarding epoxy resin adhesive for the stone material, provided by the invention, has long storage time, high binding performance on a cured material, good impacting toughness, excellent anti-stripping effect and excellent heat-resisting performance and flame-retarding performance.

Owner:安徽艾蒂贝生物股份有限公司

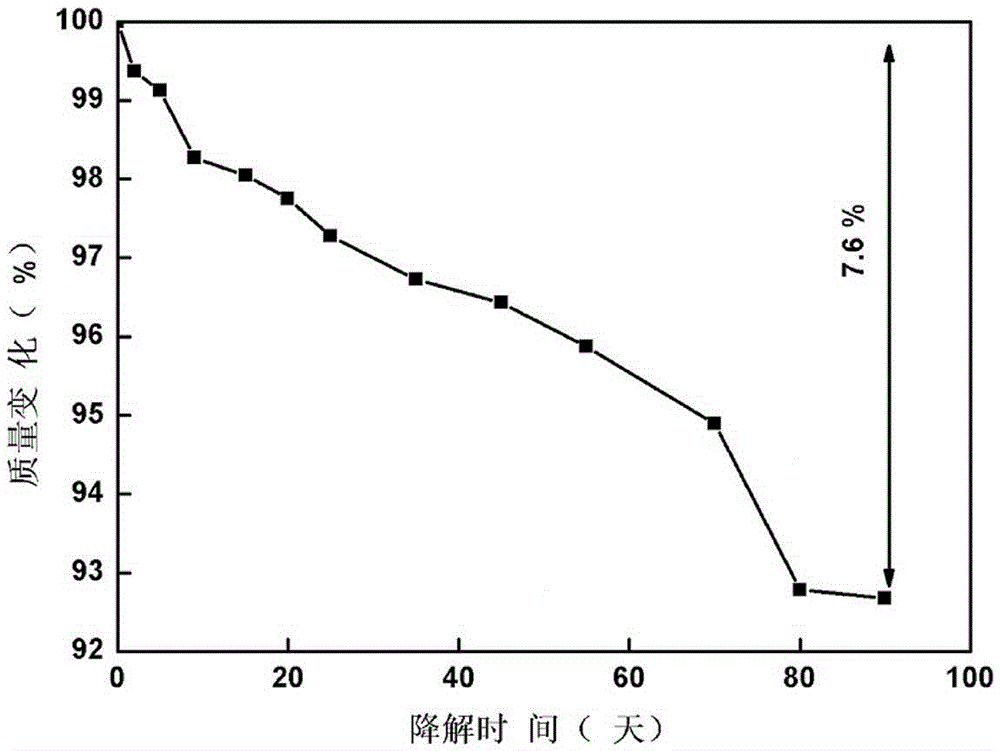

Renewable bio-based vinyl ester resin and preparation method thereof

The invention discloses renewable bio-based vinyl ester resin and a preparation method thereof. The resin is prepared by the following steps: carrying out reduced polymerization on polybasic acid, polybasic anhydride and lactic acid to obtain a block oligomer; further reacting the block oligomer and a reactive monomer to obtain the bio-based vinyl ester resin; and dissolving the bio-based vinyl ester resin into a reactive diluent, so as to obtain the renewable bio-based vinyl ester resin. With lactic acid, the polybasic anhydride and derivatives thereof as basic materials, the novel renewable bio-based vinyl ester resin is provided; the resin disclosed by the invention has the advantages of good mechanical property, relatively low shrinkage rate, low VOC emission and the like after being cured; and particularly, the resin disclosed by the invention has renewable performance and has excellent application and development prospects.

Owner:HENGSHUI XINGUANG CHEM

Recycling process of waste polycarbonate

The invention discloses a recycling process of waste polycarbonate, and relates to the field of polycarbonate recycling. The recycling process comprises the following steps: (1) pulverization and cleaning of waste polycarbonate; (2) primary melt processing and extrusion of polycarbonate; (3) secondary melt processing and extrusion of polycarbonate; (4) third melt processing and extrusion of polycarbonate; and (5) injection molding. Through multiple melt processing and extrusion and with the synergistic effect of additives, toughness of comprehensive mechanical properties of the reclaimed materials can be effectively enhanced, and the processed polycarbonate recycled materials have good flame retardancy and mechanical properties and have a wide application range.

Owner:HEFEI LONGYANG AGRI TECH CO LTD

Manufacturing method for bamboo filament brush pen

InactiveCN107718931AStable inkingInk evenlyWood treatment detailsReed/straw treatmentAcetic acidRetention time

The invention belongs to the field of writing brush processing, and in particular relates to a method for making a bamboo silk writing brush, comprising the following steps: 1) modifying nylon hair to obtain modified nylon hair; 2) separately making rabbit hair, duck hair and pig hair Soak in soapy water for 45-60 minutes, then soak in starch solution for 20-35 minutes, take it out and soak in acetic acid for 3-5 minutes; Soak in water for 4-5 hours, take it out and steam it for 1-2 hours, take it out and make bamboo silk; 4) Mix the treated rabbit hair, duck hair, pig hair, modified nylon hair and bamboo silk in proportion with a carding machine , Pick a bundle of mixed refill hair when making a refill, spread this bundle of hair on a flat plate, after grooming, and then roll it up from one end to make a conical pen tip, and put the tied pen tip into To the pen barrel, add glue to connect. The brush made by the invention is elastic, more durable and has a long storage time.

Owner:广安市广安区长乐小学校

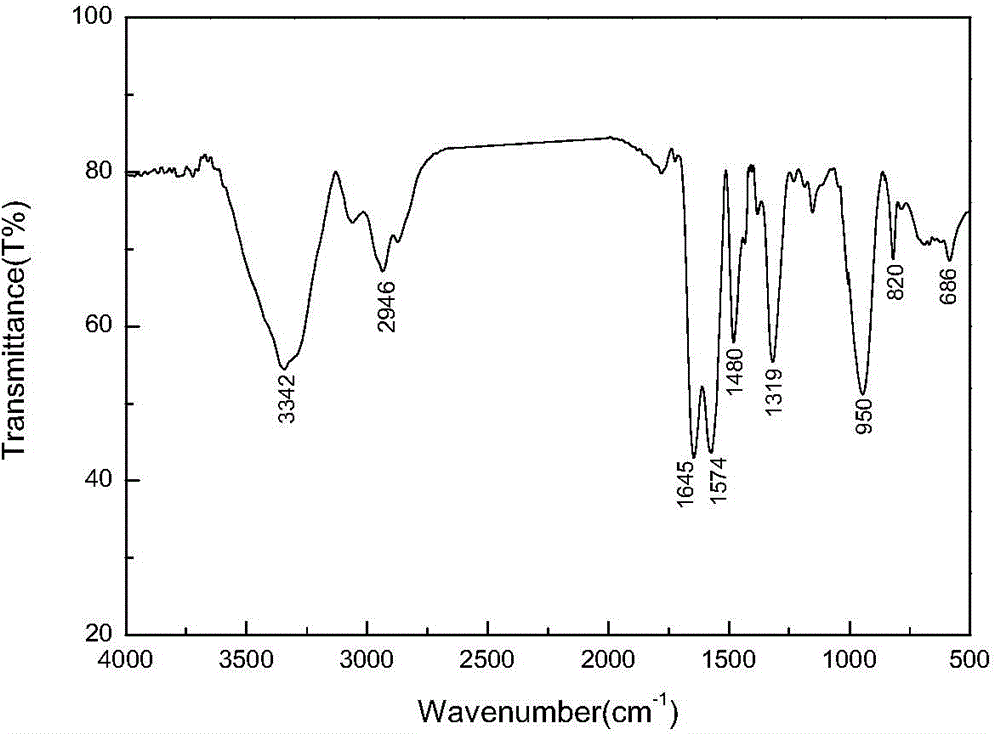

Preparation method of modified cyanate ester resin with low volatility

The invention discloses a preparation method of a modified cyanate ester resin with low volatility, and belongs to the technical field of preparation of high polymer materials. In the prior art, the condensable volatile matter loss and the mass loss of the existing epoxy resin toughened and modified cyanate ester resin in a space high-vacuum environment are high so as to highly affect a satelliteimaging system, and the heat resistance of the epoxy resin toughened and modified cyanate ester resin can be reduced. A purpose of the invention is to solve the problems in the prior art. According tothe invention, phenolphthalein polyethersulfone containing a benzene ring structure and a polyimide thermoplastic resin with a high glass transition temperature are selected to modify a cyanate esterresin to obtain the modified cyanate ester resin with low volatility, and the heat resistance of the resin is equivalent to the heat resistance of the cyanate ester resin body; and the modified cyanate ester obtained by the preparation method has the characteristics of good processing technology, excellent heat resistance, low volatility and the like, can meet the actual requirements of use of asatellite optical imaging system in an extreme environment, and can be widely applied to a light shield and an optical machine structural member of a satellite optical remote sensing system.

Owner:HARBIN INST OF TECH

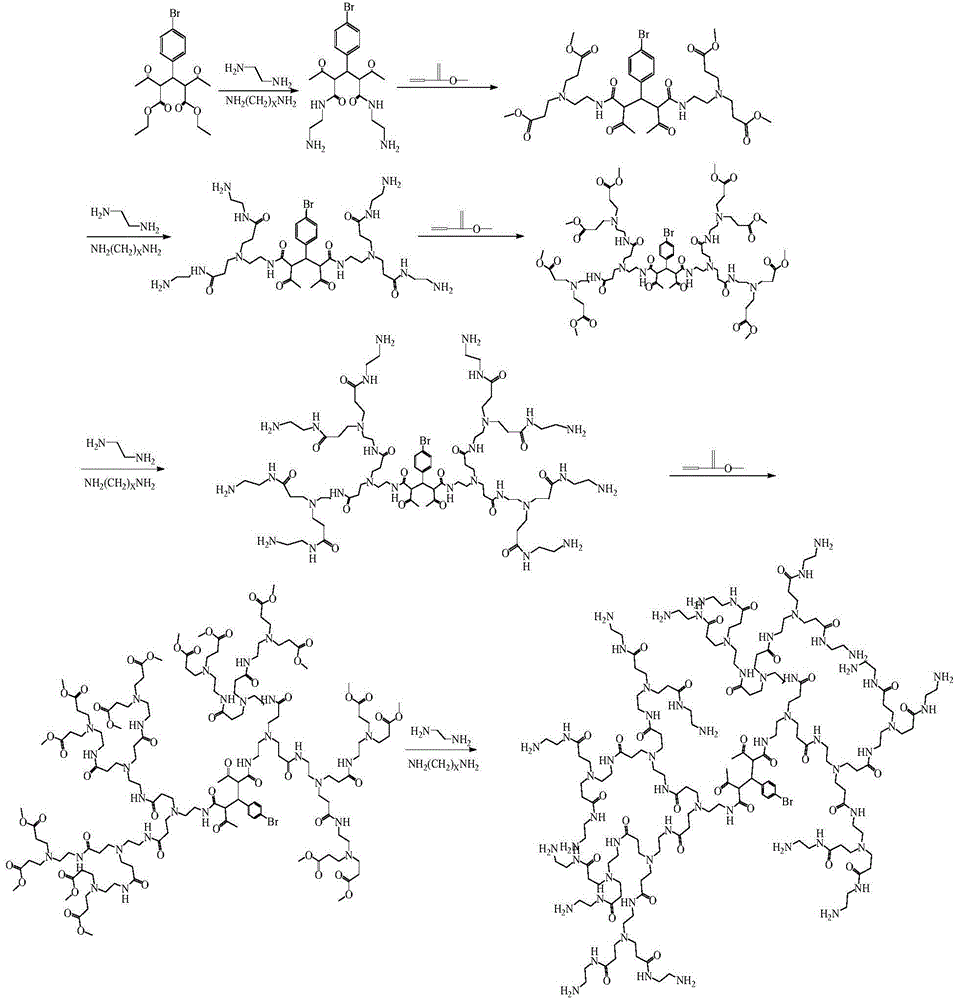

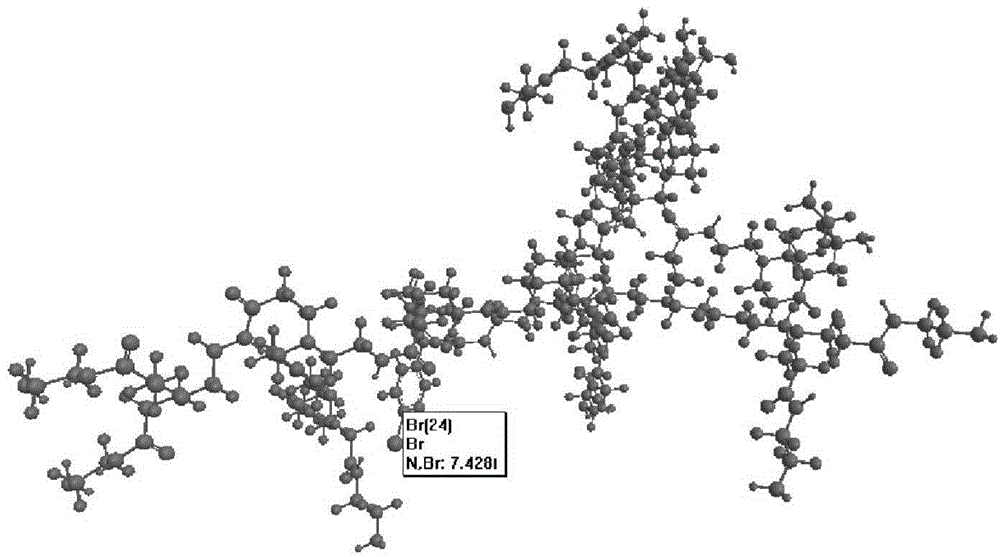

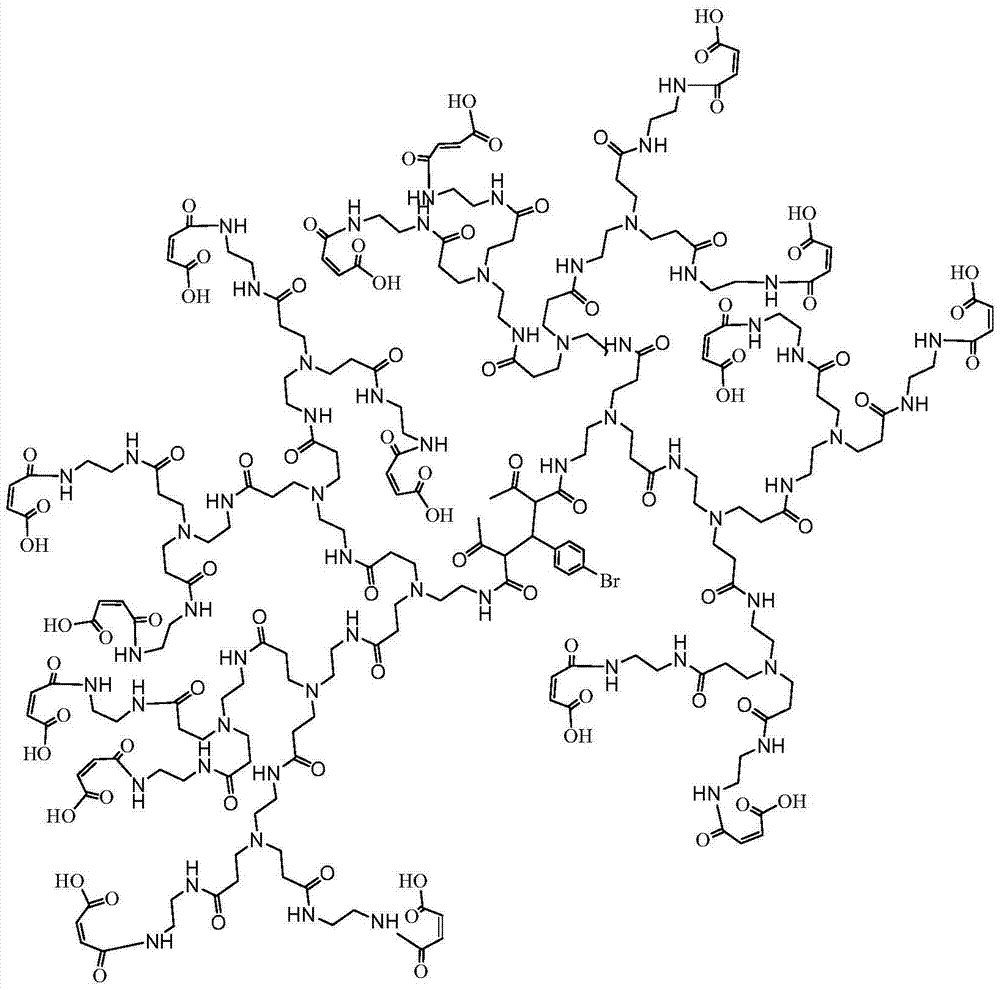

Resin framework monomer taking 2,4-diacetyl-3-(4-bromophenyl)ethyl glutarate as core as well as preparation method and application of resin framework monomer

InactiveCN104610083AImprove salt and shear resistanceHigh viscosityOrganic compound preparationCarboxylic acid amides preparationSalt resistancePolymer science

The invention provides a resin framework monomer taking 2,4-diacetyl-3-(4-bromophenyl)ethyl glutarate as a core. The molecular formula of the resin framework monomer is as shown in a formula I. The invention further provides a preparation method of the resin framework monomer, and the method comprises the following steps: mixing 2,4-diacetyl-3-(4-bromophenyl)ethyl glutarate and aliphatic diamine for modification to generate a reaction core, and performing grafting on the reaction core alternately to generate a 0.5-genreation product, a 1-genreation product, 1.5-genreation product, 2-genreation product and a 2.5-genreation product in sequence and finally generate a 3-genreation product, namely the resin framework monomer, wherein methyl acrylate is adopted as a reactant in reaction processes of half-generation preparation, and aliphatic diamine is adopted as a reactant in reaction processes of whole-generation preparation. The resin framework monomer prepared by the invention has a rigid structural main chain and thus has favorable salt resistance and thermal stability, and the effect is improved when the resin framework monomer is applied in an oilfield oil displacement polymer.

Owner:SOUTHWEST PETROLEUM UNIV

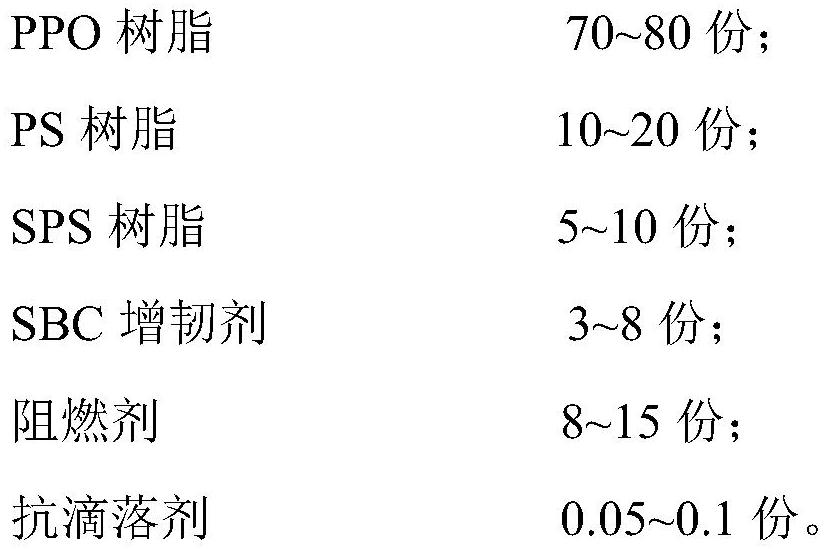

Transparent flame-retardant MPPO resin composition and preparation method thereof

The invention relates to a transparent flame-retardant MPPO resin composition. The resin composition comprises PPO resin, PS resin, SPS resin, an SBC toughening agent, a flame retardant and an anti-dripping agent. According to the invention, five components with excellent compatibility, namely PPO, PS, SPS, SBC and a phosphate flame retardant, are selected and blended to obtain a transparent matrix; sBC is adopted as a toughening agent, preferably, the content of polybutadiene is 15-30%, and due to the fact that the content of polybutadiene is low, when the polybutadiene is dispersed in a matrix, the phase domain of the polybutadiene is small enough, and therefore the transparency of the material is not affected. Meanwhile, the SPS resin is also added and is opaque crystalline resin, and when the SPS resin is blended with the PPO / PS resin, the compatibility is good enough, so that even if the crystallization behavior of the SPS is changed, the crystallinity is obviously reduced, and the transparency of the material is not influenced.

Owner:SHANGHAI KUMHOSUNNY JINSHAN PLASTICS CO LTD +1

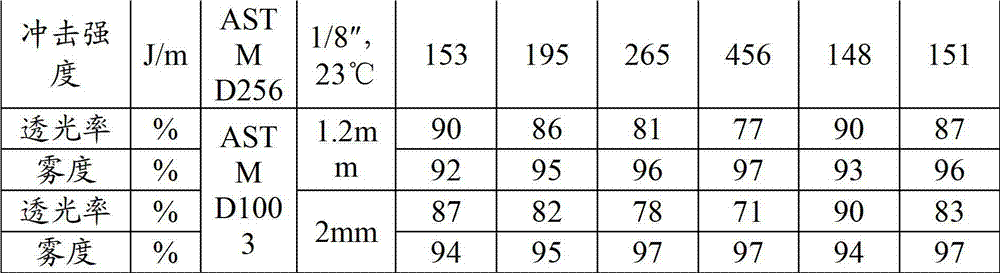

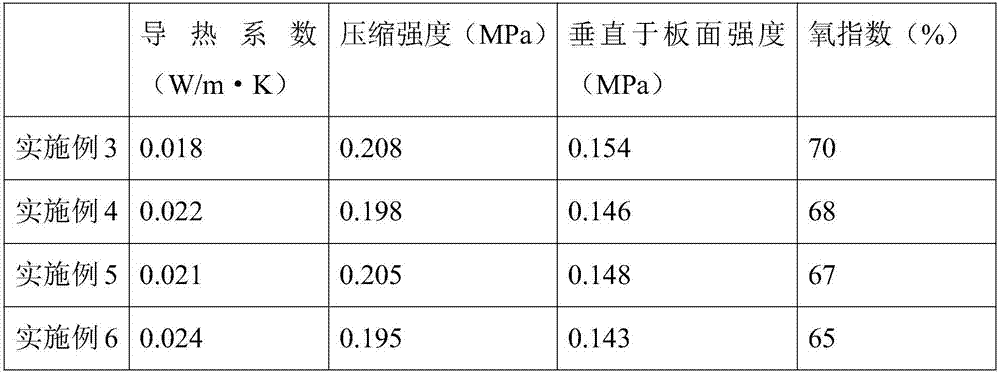

Phenolic aldehyde insulation board for external wall and preparation method of phenolic aldehyde insulation board

The invention discloses a phenolic aldehyde insulation board for an external wall and a preparation method of the phenolic aldehyde insulation board. The phenolic aldehyde insulation board contains the following raw materials in parts by weight: 65-75 parts of phenolic resin, 10-20 parts of polyether modified resin, 3-6 parts of plant fibers, 5-10 parts of defoaming agent, 10-15 parts of an acidic curing agent and 3-6 parts of a flexibilizer, wherein the defoaming agent is a mixture of diethyl ether, n-pentane and carbon dioxide, and the flexibilizer is mainly prepared from water glass, sodium metaaluminate and polyethylene glycol. The preparation method comprises the following steps: (1) uniformly mixing the phenolic resin, the acidic curing agent and the flexibilizer at 40-60 DEG C, so as to obtain a mixture A; and (2) uniformly mixing and stirring the mixture A, the polyether modified resin, the plant fibers and the defoaming agent to obtain a mixture, rapidly pouring the mixture into a preheated mold for foaming, and carrying out curing. The phenolic aldehyde insulation board is high in strength and oxygen index and low in heat conductivity coefficient.

Owner:合肥泓定科技有限公司

Building material and preparation method thereof

InactiveCN109180106AGood environmental characteristicsStrong environmental protectionFiberPolyvinyl alcohol

The invention discloses a building material. The building material comprises, by weight, 5-25 parts of triethanolamine, 6-18 parts of silicon oxide, 6-18 parts of heavy calcium carbonate, 2-18 parts of polyvinyl alcohol, 3-13 parts of expanded perlite, 3-15 parts of sodium silicate, 1-17 parts of deionized water, 3-15 parts of Portland cement, 4-18 parts of glass beads, 4-18 parts of fly ash, 4-18parts of polyacrylonitrile fiber, 4-18 parts of modified epoxy resin, 3-13 parts of 2-hydroxy-4-methoxybenzophenone, 6-18 parts of heptyl 4-hydroxybenzoate, 3-17 parts of sulfonated melamine-formaldehyde resin and 3-13 parts of brominated bisphenol A epoxy resin. The building material has the advantages of good fracture resistance, good ultraviolet radiation resistance and long service life.

Owner:孙浩

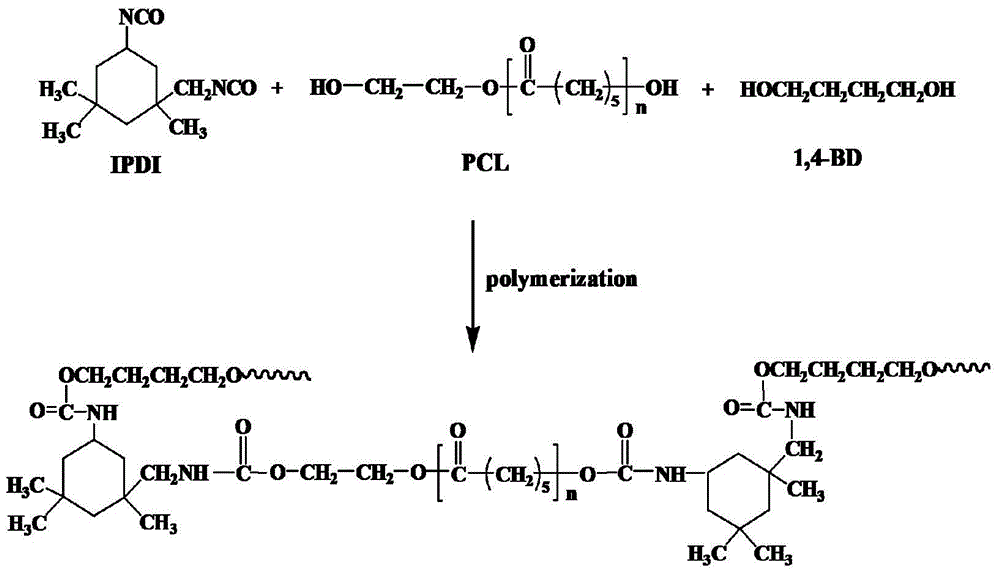

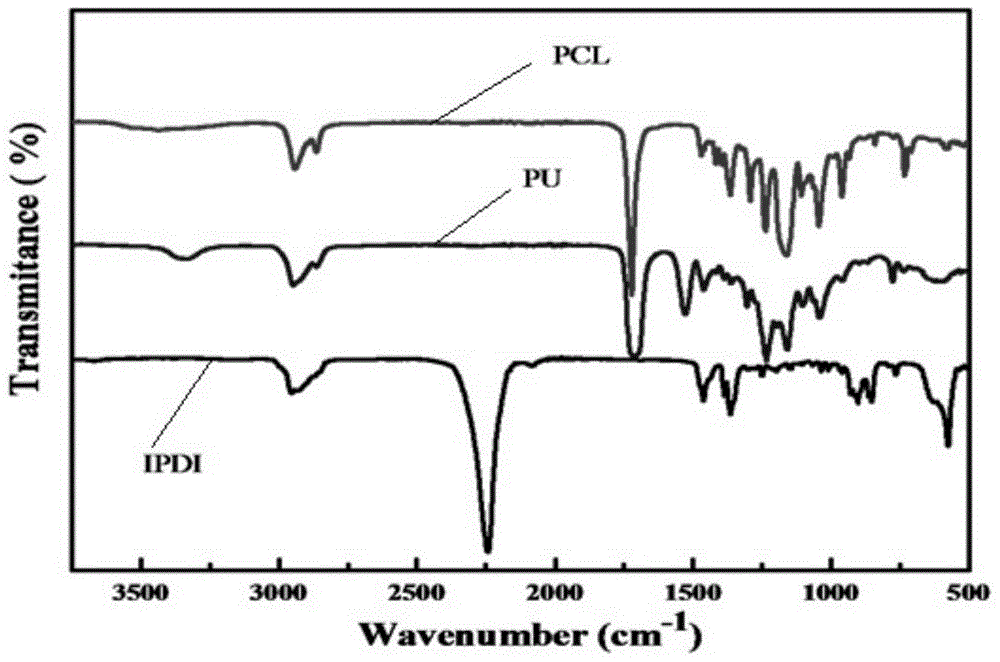

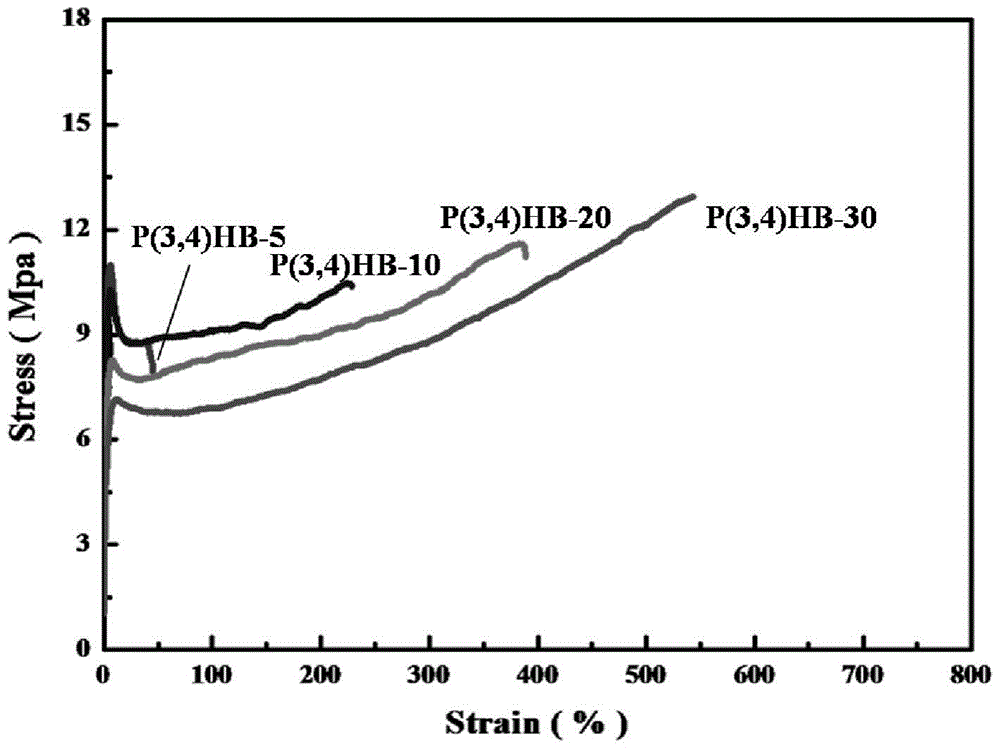

A linear polyurethane elastomer toughening agent for toughening biological polyester pha and its preparation method and application

Owner:NANJING FORESTRY UNIV

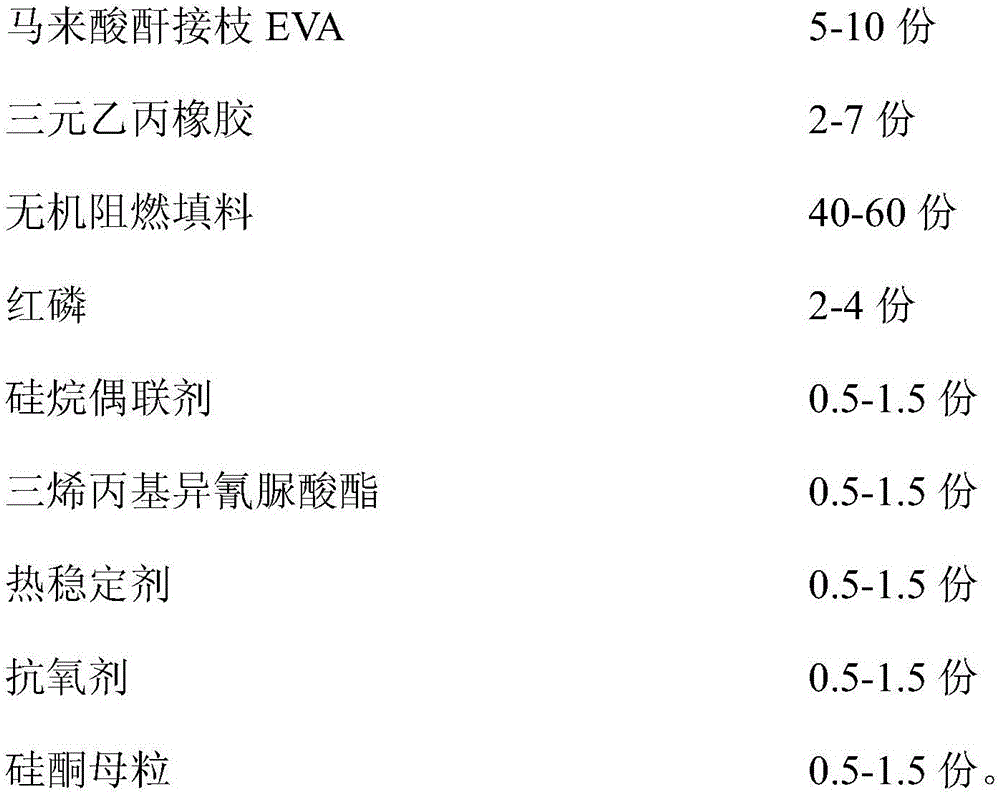

A kind of cable material and its preparation method and application

ActiveCN106380861BGood compatibilityImprove flame retardant performanceInsulated cablesInsulated conductorsPolymer scienceTriallyl isocyanurate

The invention provides a cable material, and a preparation method and application thereof. The cable material is prepared from the following raw materials in parts by weight: 10-30 parts of polyethylene, 5-20 parts of silicone rubber, 5-15 parts of maleic anhydride graft EVA (ethylene-vinyl acetate), 0.5-10 parts of ethylene propylene diene monomer rubber, 40-65 parts of flame retardant, 2-5 parts of red phosphorus, 0.1-2 parts of silane coupling agent and 0.1-2 parts of triallyl isocyanurate. The preparation method comprises the following steps: banburying, extrusion and irradiation crosslinking. The cable material provided by the invention has the advantages of high flexibility, favorable insulativity, favorable flame retardancy, favorable oil resistance and favorable cold resistance, and is applicable to automobile wire insulating materials.

Owner:JIANGSU DASHENG POLYMER

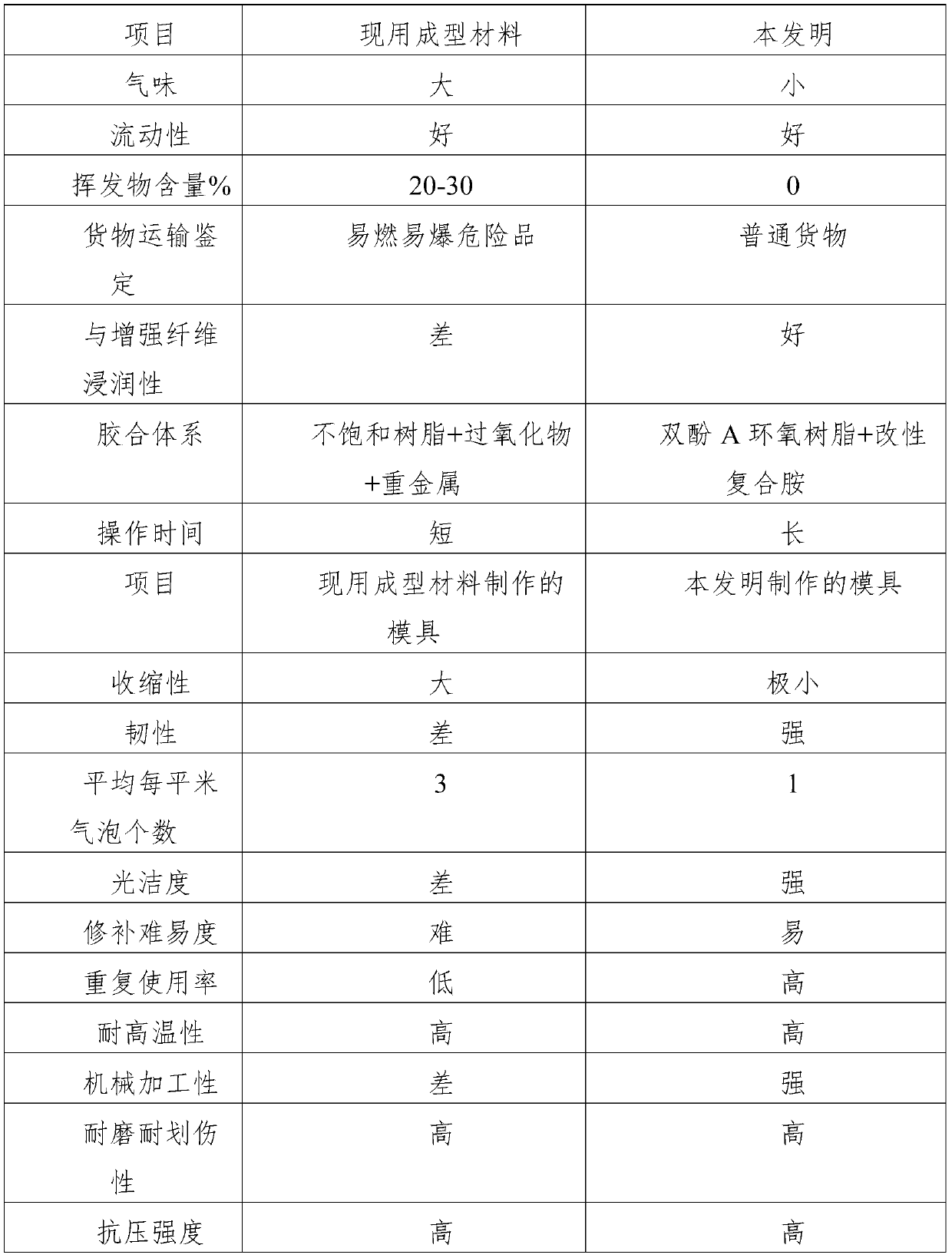

Epoxy adhesive for preparing assembled prefabricated wallboard mold and preparation method of epoxy adhesive

InactiveCN111592846AReduce volatilityHas a toughening effectNon-macromolecular adhesive additivesEpoxy resin adhesivesPolyamideDibutyltin dilaurate

The invention provides an epoxy adhesive for preparing an assembled prefabricated wallboard mold and a preparation method of the epoxy adhesive. The epoxy adhesive is prepared from the following raw materials in parts by weight: 35 to 40 parts of bisphenol A epoxy resin E51; 5 to 10 parts of glycidyl ether; 0.1 to 0.3 part of a defoaming agent; 0.1 to 0.3 part of coupling agent, 50 to 60 parts ofactive silica powder, 5 to 10 parts of aluminum hydroxide, 30 to 40 parts of 4 '-diaminodiphenylmethane, 20 to 30 parts of propylene carbonate, 10 to 20 parts of Mannich amine, 10 to 40 parts of polyamide, 0.1 to 0.3 part of dibutyltin dilaurate and 0.1 to 0.5 part of thixotropic agent. The assembled building prefabricated wallboard mold manufactured through the scheme is high in compressive strength, high in temperature resistance, good in toughness, high in abrasion resistance, high in scratch resistance, high in surface smoothness, high in reuse rate and good in durability. The number of assembled building prefabricated wallboard molds manufactured through one mold is increased by multiple times, the manufacturing cost of each assembled building prefabricated wallboard is reduced to onefourth of the original manufacturing cost, and great economic benefits are achieved.

Owner:石家庄广科新材料有限公司

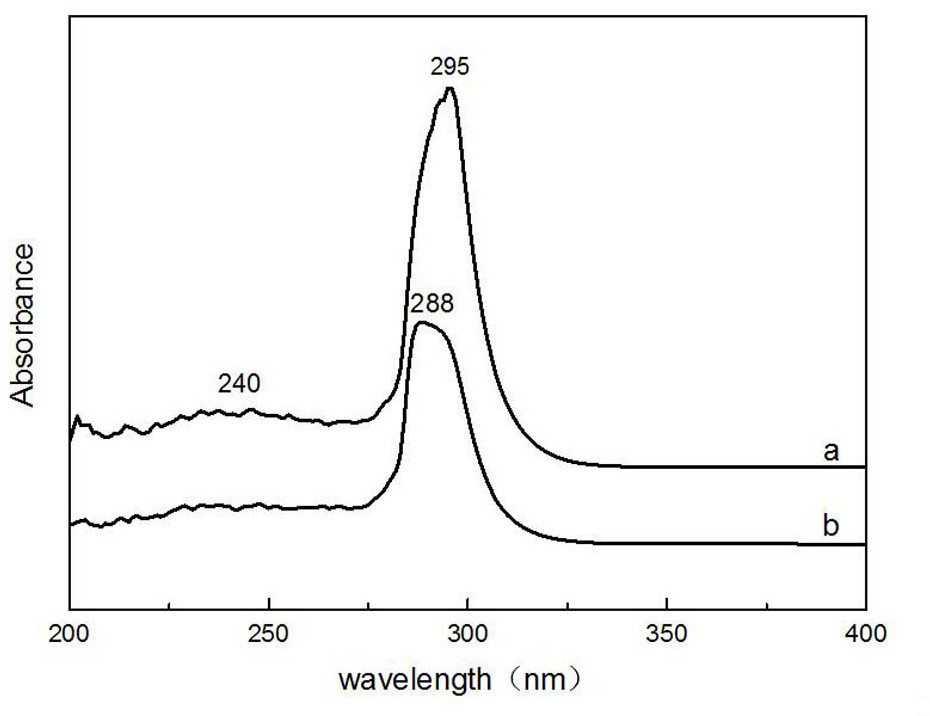

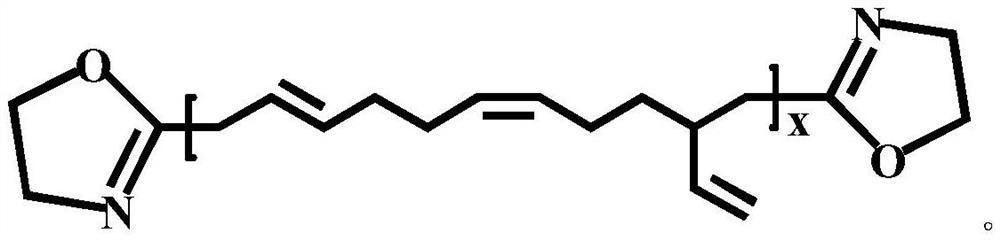

Oxazoline-terminated polybutadiene compound, and preparation method and application thereof

The invention belongs to the field of high polymer materials, and mainly relates to an oxazoline-terminated polybutadiene compound, a preparation method thereof, and an application of the compound asa chain extender in the field of waste plastic high-valued treatment. According to the oxazoline-terminated polybutadiene compound, carboxyl-terminated polybutadiene, thionyl chloride and ethanolaminereact in an organic solvent under a certain condition to prepare the oxazoline-terminated polybutadiene compound. Carboxyl-terminated polybutadiene is an elastomer, has a toughening effect, and has good compatibility with high impact polystyrene, an acrylonitrile-butadiene-styrene copolymer and polypropylene, and oxazoline groups can react with carboxyl groups generated by aging, so that molecular chain repair and reaction compatibilization are realized. The method has the characteristics of simplicity in operation, mild reaction conditions, high target product azoline-terminated polybutadiene oxazoline content, wide application range and the like, is environment-friendly, and has wide application prospects in the field of waste plastic high-valued treatment.

Owner:ZHONGBEI UNIV

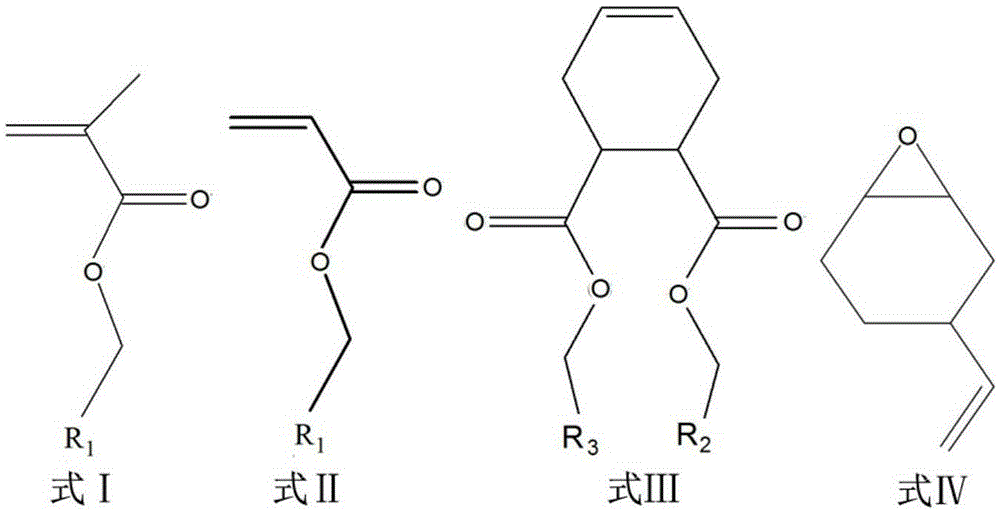

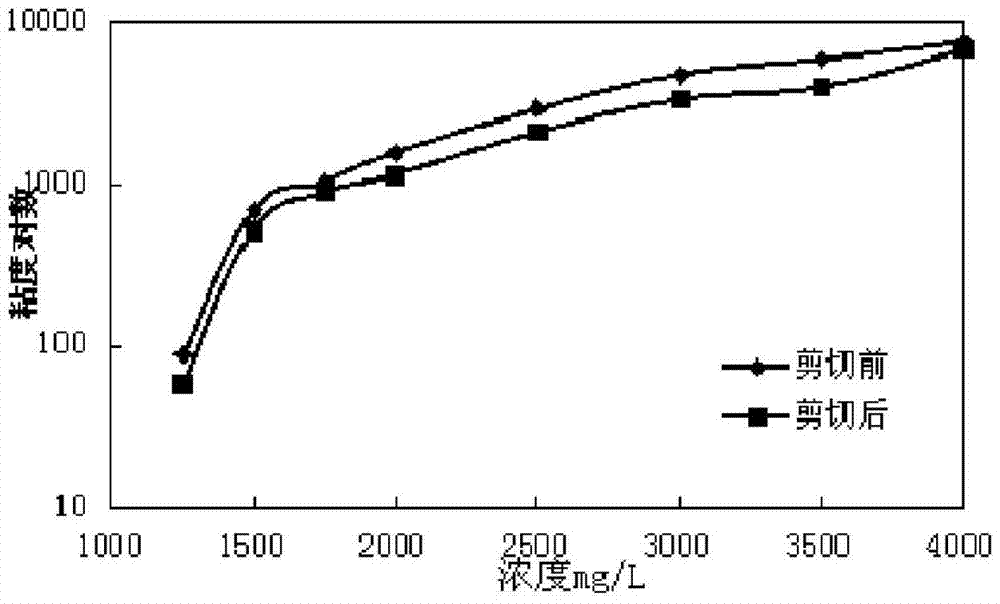

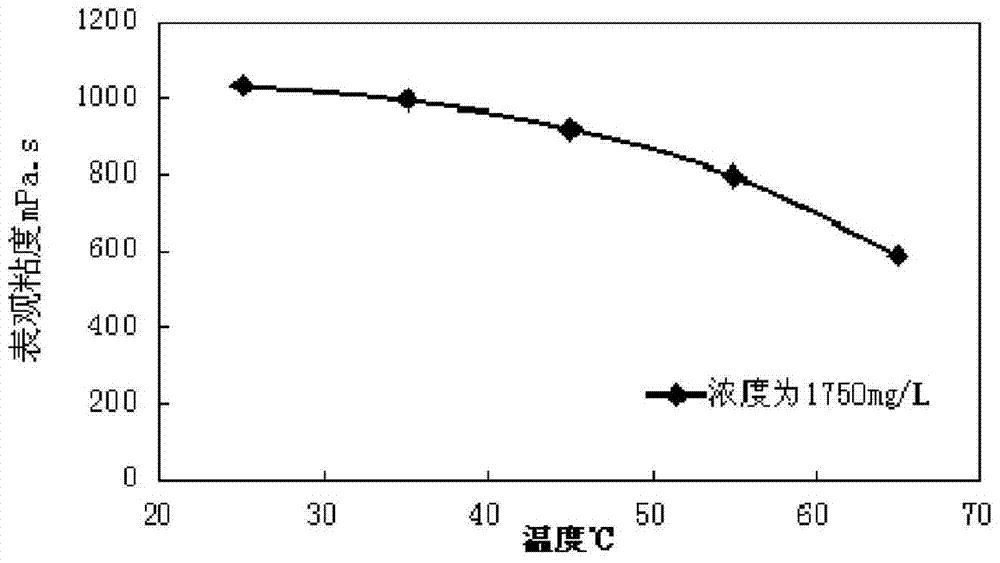

A water-soluble oil displacement polymer with rigid core-shell structure and its preparation method

InactiveCN104672408BHas a toughening effectHigh molecular weightDrilling compositionPolymer scienceReaction temperature

The invention provides a water-soluble oil-displacing polymer with a rigid core-shell structure, comprising a copolymer of acrylamide, sodium acrylate, dimethylallyl-p-alkylbenzyl ammonium chloride and functionalized backbone monomers, Average molecular weight is 7,000,000, and structure is as shown in I; Also provide above-mentioned polymer preparation method: branched polyamidoamine skeleton monomer solution is added dropwise in maleic anhydride solution, feed nitrogen simultaneously, in ice salt Reaction in the bath to obtain the functionalized skeleton monomer; then weigh the following raw materials in parts by weight: 14.3-20.5 parts of acrylic acid, 56.16-72.2 parts of acrylamide, 1.0-1.74 parts of dimethyl allyl-p-alkylbenzyl chloride Ammonium and 0.05-0.16 parts of functionalized backbone monomers, adding co-solvent, chain transfer agent and redox initiator, and reacting at 45-55°C for 5-9 hours at a constant temperature. The polymer of the invention has large molecular weight, high viscosity, good thermal stability and shear resistance.

Owner:SOUTHWEST PETROLEUM UNIV

A kind of self-toughening benzoxazine thermosetting resin and preparation method thereof

The invention provides a self-toughening benzoxazine thermosetting resin with the structure shown in formula I. The present invention introduces long alkyl chains into the chemical structure of benzoxazine, so as to play a role of toughening, so that the obtained benzoxazine thermosetting resin has the characteristic of self-toughening; at the same time, through the form of chemical bonds, the long The introduction of the alkyl chain into the chemical structure of benzoxazine effectively avoids the problem of precipitation due to poor compatibility of traditional toughening agents. In addition, in the self-toughening benzoxazine thermosetting resin provided by the present invention, due to the addition of long alkyl chains, the concentration of oxazine rings is effectively diluted, thereby also significantly reducing the concentration of the self-toughening benzoxazine. The curing temperature of a thermosetting resin. In addition, long alkyl chains are introduced into the structure of benzoxazine, which can play a good role in internal plasticization, so the toughness of the self-toughening benzoxazine thermosetting resin cured product is also greatly improved .

Owner:GUIZHOU INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com