A water-soluble oil displacement polymer with rigid core-shell structure and its preparation method

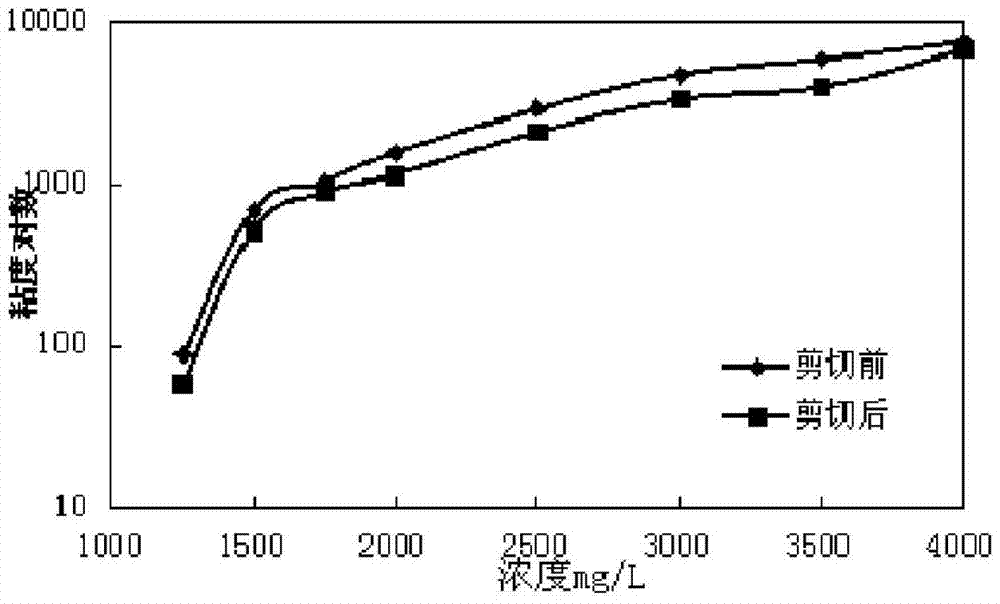

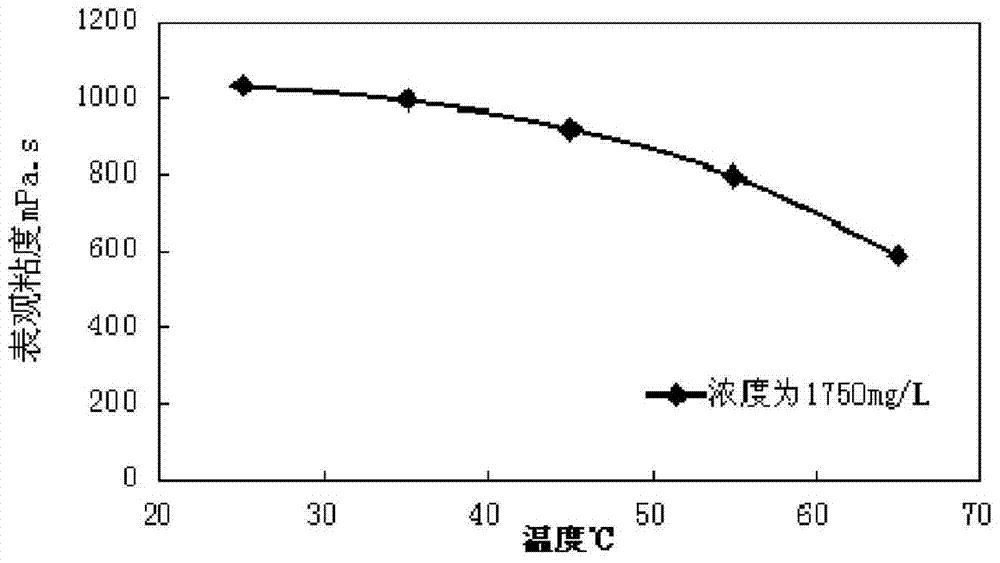

A technology of oil displacement polymer and shell structure, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of slow polymer dissolution, poor temperature resistance, poor salt resistance, etc., and achieve good anti-corrosion Shear properties, effects of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: A water-soluble oil displacement polymer with a rigid core-shell structure:

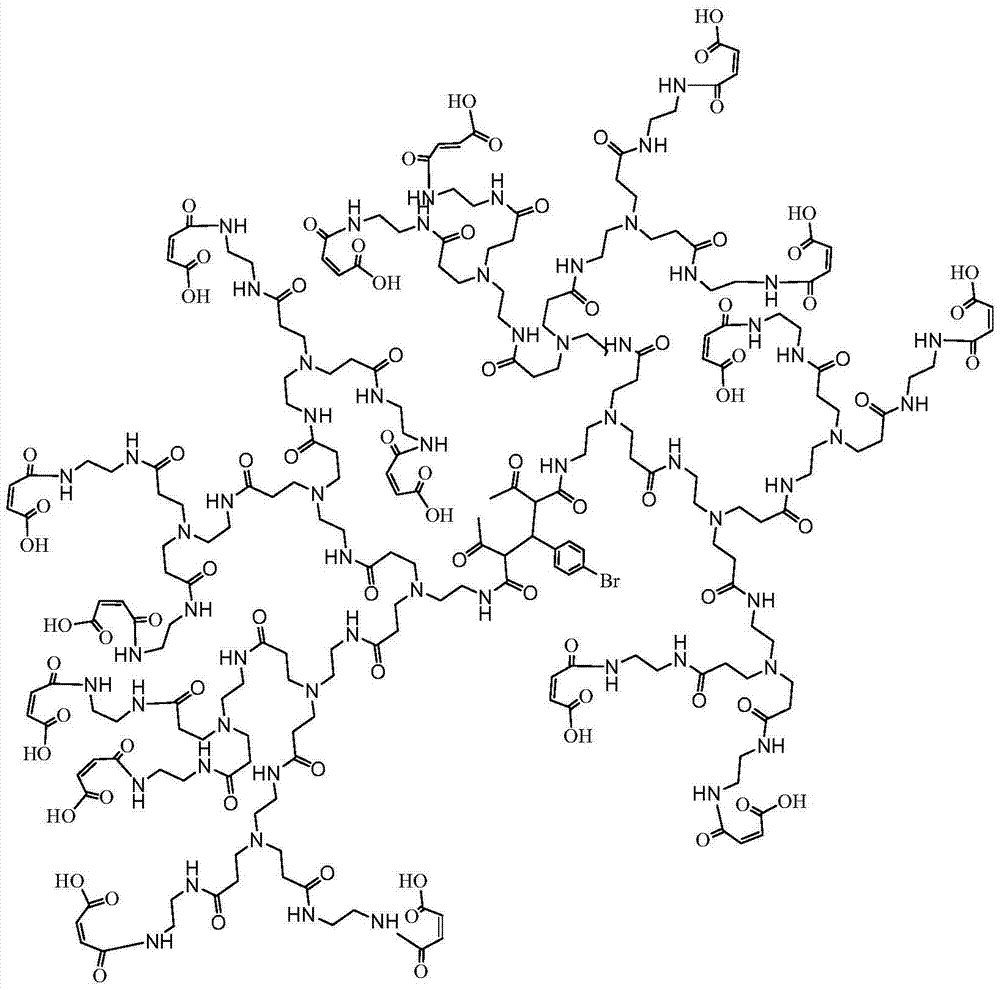

[0030] The branched polyamide-amine backbone monomer with 2,4-diacetyl-3-(4-bromophenyl)diethyl glutarate as the core and maleic anhydride in a molar ratio of 1:0.8, Dissolve in dimethyl sulfoxide respectively to prepare a skeleton monomer solution and a maleic anhydride solution with a mass concentration of 0.095%. The skeleton monomer solution is slowly added dropwise to the maleic anhydride solution. During the dripping process Blow nitrogen through, and place the reaction system in an ice-salt bath. When the color of the solution gradually changes from dark yellow to brown, test the pH at about 4.5-5.5, stop the dripping, continue stirring for 5 hours and then stop, use chloroform Repeated washing and filtering reaction product to obtain functionalized skeleton monomer; image 3 As shown, it is a macromolecule synthesized with a rigid structural group as the core, and the peripher...

Embodiment 2

[0032] Example 2: A water-soluble oil displacement polymer with a rigid core-shell structure:

[0033] The branched polyamide-amine backbone monomer with 2,4-diacetyl-3-(4-bromophenyl)diethyl glutarate as the core and maleic anhydride in a molar ratio of 1:1.9, Dissolve them in dimethyl sulfoxide to prepare a skeleton monomer solution and a maleic anhydride solution with a mass concentration of 1%. The skeleton monomer solution is slowly added dropwise to the maleic anhydride solution. During the dropping process Blow nitrogen through, and place the reaction system in an ice-salt bath. When the color of the solution gradually changes from dark yellow to brown, test the pH at about 4.5-5.5, stop the dripping, continue stirring for 4.5 hours and then stop, use chloroform Repeated washing and filtering reaction products to obtain functionalized skeleton monomers;

[0034] To synthesize a water-soluble oil displacement polymer with a rigid core-shell structure: weigh the following par...

Embodiment 3

[0035] Example 3: A water-soluble oil displacement polymer with a rigid core-shell structure:

[0036] The branched polyamide-amine backbone monomer with 2,4-diacetyl-3-(4-bromophenyl)diethyl glutarate as the core and maleic anhydride in a molar ratio of 1:1.2, Dissolve in dimethyl sulfoxide respectively to prepare a skeleton monomer solution and a maleic anhydride solution with a mass concentration of 0.098%. The skeleton monomer solution is slowly added dropwise to the maleic anhydride solution. During the process, nitrogen is blown and the reaction system is placed in an ice-salt bath. When the color of the solution gradually changes from dark yellow to brown, the test pH is about 4.5-5.5, stop the dripping, continue stirring for 4 hours and then stop. The reaction product was washed and filtered repeatedly with chloroform to obtain a functionalized skeleton monomer;

[0037] To synthesize a water-soluble oil displacement polymer with a rigid core-shell structure: weigh the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com