A kind of cable material and its preparation method and application

A cable material and wire technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem that the flexibility of the cable material does not meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

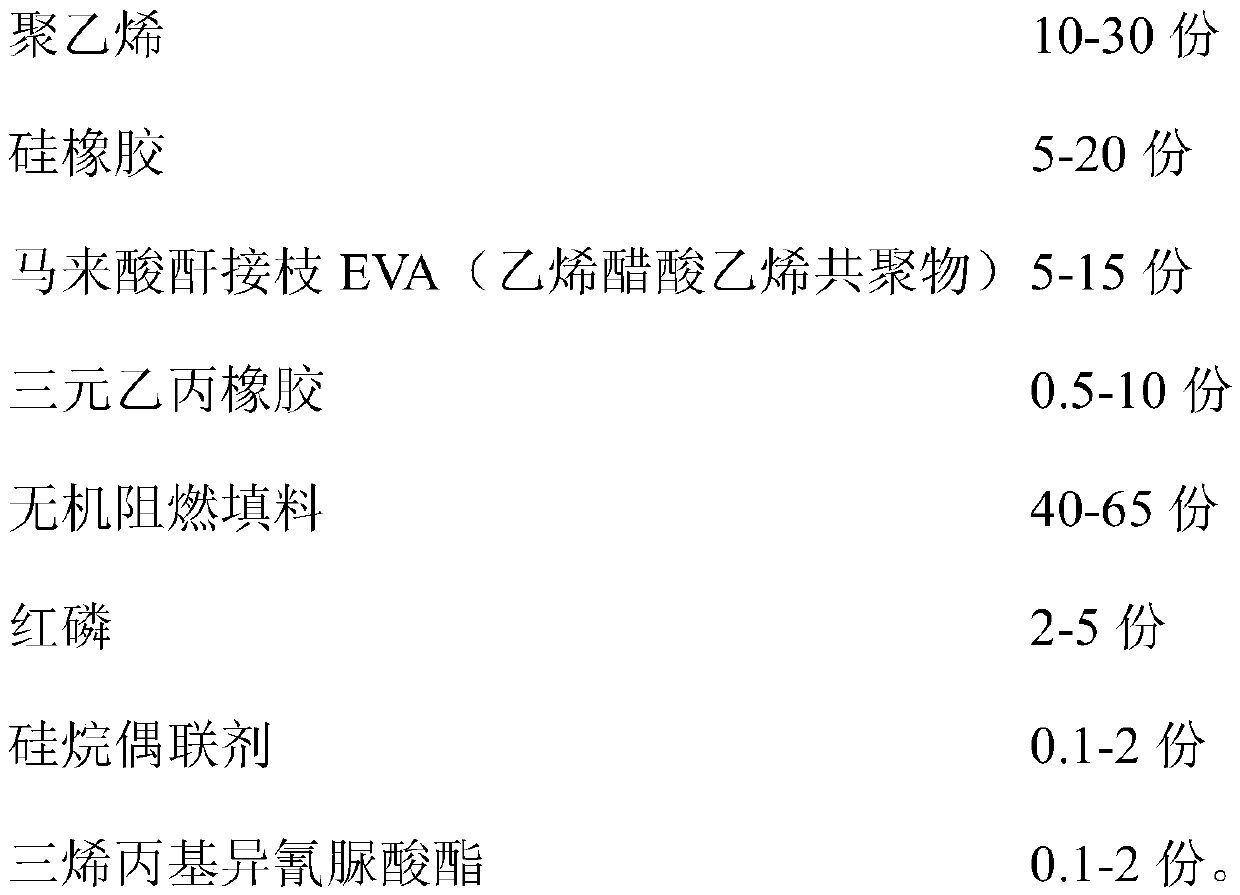

[0080] In this embodiment, the cable material is prepared from the following raw materials in parts by weight:

[0081]

[0082] Among them, the polyethylene is linear low-density polyethylene, the molecular weight is 100,000, and the melt index is 2g / 10min; the silicone rubber is methyl vinyl silicone rubber; the grafting rate of maleic anhydride grafted EVA is 1.5%, and the The mass percentage is 30%; the molecular weight of the EPDM rubber is 50,000, the Mooney viscosity is 30, and the Shore A hardness is 20; the inorganic flame-retardant filler is aluminum hydroxide.

[0083] The preparation method is as follows:

[0084] (1) Add the above-mentioned raw materials into the internal mixer for internal mixing. After the temperature of the internal mixer reaches 125°C, turn over the materials. Before the internal mixing stops, clean the silo and the feeding port. The time is 25 minutes, and the dough is obtained;

[0085] (2) Extrude and granulate the dough obtained in st...

Embodiment 2

[0089] In this embodiment, the cable material is prepared from the following raw materials in parts by weight:

[0090]

[0091] Among them, polyethylene is high-density polyethylene with a melt index of 3g / 10min; the silicone rubber is a mixture of methyl vinyl silicone rubber and methyl phenyl vinyl silicone rubber; the grafting rate of maleic anhydride grafted EVA is 1 %, the mass percentage of VA is 32%; the molecular weight of EPDM rubber is 100,000, the Mooney viscosity is 40, and the Shore A hardness is 30; the inorganic flame retardant filler is magnesium hydroxide.

[0092] The preparation method is as follows:

[0093] (1) Add the above-mentioned raw materials into the internal mixer for internal mixing. After the temperature of the internal mixer reaches 128°C, turn over the materials. Before the internal mixing stops, clean the silo and the feeding port. The time is 23 minutes, and the dough is obtained;

[0094] (2) The dough obtained in step (1) is extruded ...

Embodiment 3

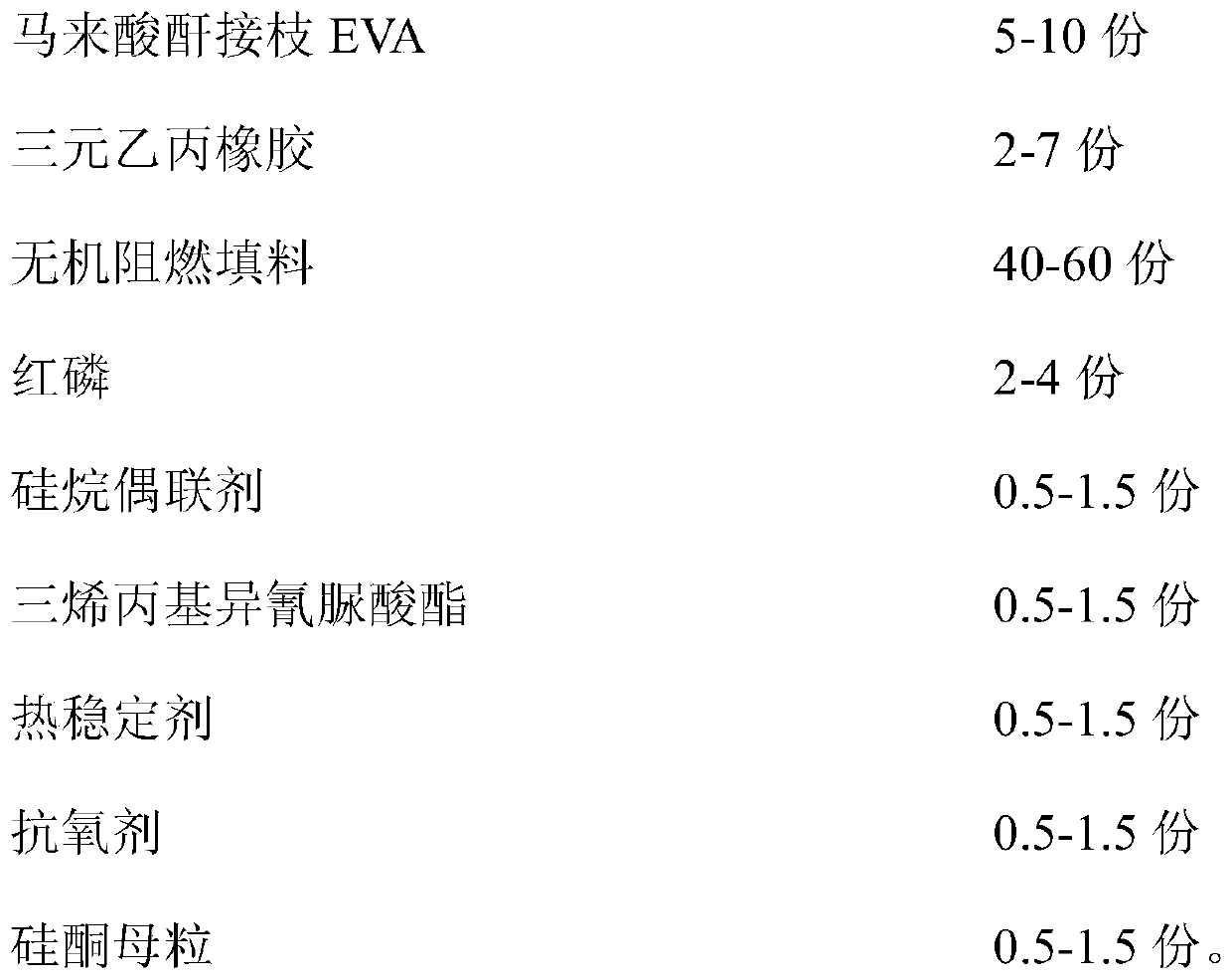

[0098] In this embodiment, the cable material is prepared from the following raw materials in parts by weight:

[0099]

[0100]

[0101]Among them, the polyethylene is linear low-density polyethylene, the molecular weight is 110,000, and the melt index is 3g / 10min; the silicone rubber is methyl vinyl silicone rubber; the grafting rate of maleic anhydride grafted EVA is 2%, and the The mass percent content is 35%; the molecular weight of EPDM rubber is 150,000, the Mooney viscosity is 70, and the Shore A hardness is 50; the inorganic flame-retardant filler is aluminum hydroxide treated with surface activation; the heat stabilizer is Zinc stearate; antioxidant tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0102] The preparation method is as follows:

[0103] (1) Add the above-mentioned raw materials into the internal mixer for internal mixing. After the temperature of the internal mixer reaches 130°C, turn over the materials. Before ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com