Epoxy adhesive for preparing assembled prefabricated wallboard mold and preparation method of epoxy adhesive

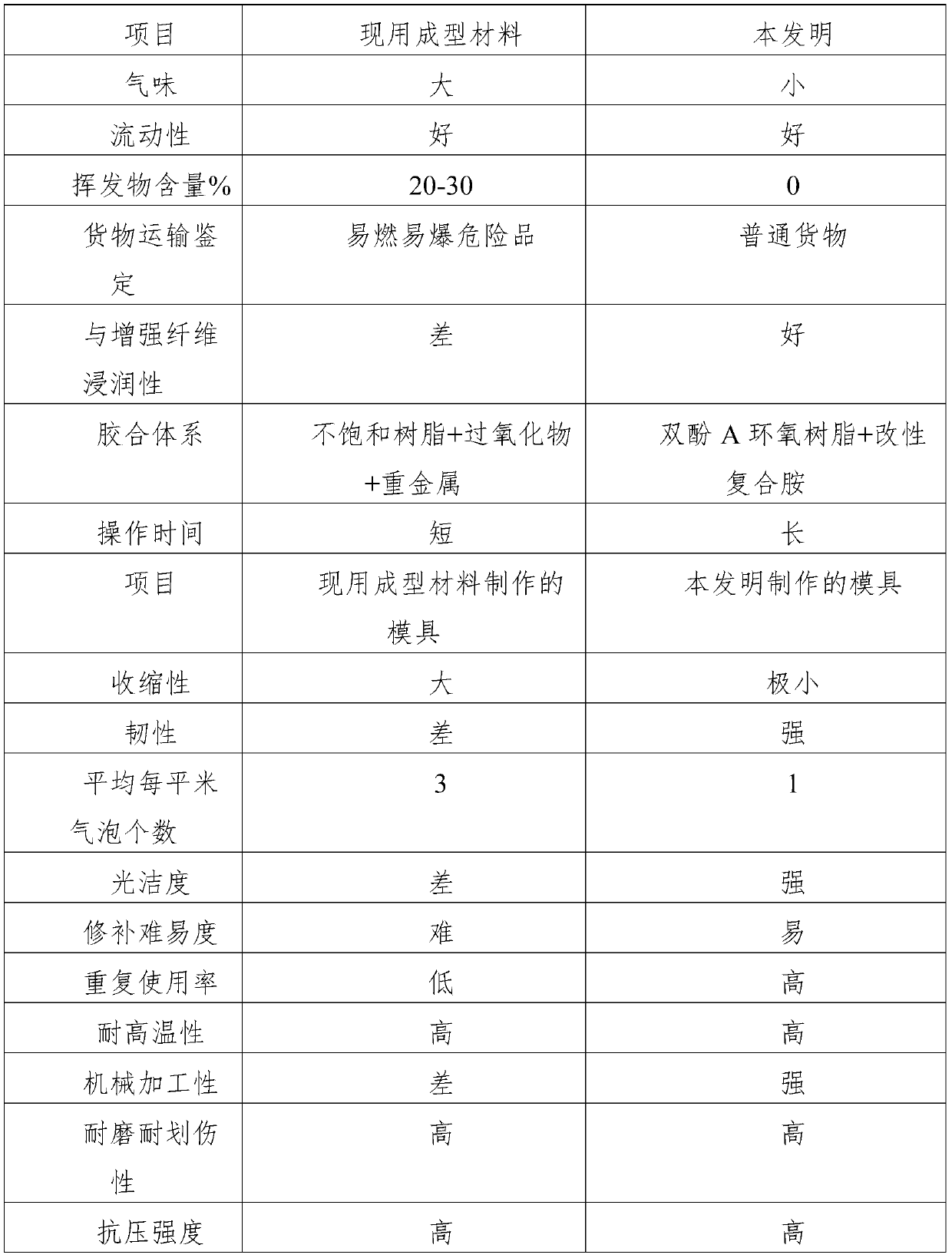

A prefabricated wallboard, epoxy glue technology, applied in the direction of epoxy glue, adhesive, adhesive type, etc., can solve the problems of increasing the risk factor, high brittleness, high odor, etc., to achieve strong wear resistance, anti- High compressive strength and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An epoxy adhesive for preparing an assembled prefabricated wallboard mold, the composition of the epoxy adhesive includes the following raw materials in parts by weight: 35 parts of bisphenol A epoxy resin E51, 10 parts of glycidyl ether, defoamer 0.1 parts, 0.3 parts of coupling agent, 50 parts of active silica powder, 10 parts of aluminum hydroxide, 30 parts of 4' diaminodiphenylmethane, 30 parts of propylene carbonate, 10 parts of Mannisamine, 40 parts of polyamide, dilaurel 0.1 part of dibutyltin acid and 0.5 part of thixotropic agent.

[0026] The preparation method of the epoxy adhesive for the preparation of the assembled prefabricated wallboard mold comprises the following steps:

[0027] (1) Weigh the raw materials of component A according to the number of parts by mass: bisphenol A epoxy resin E51, glycidyl ether, defoamer, coupling agent, and add each component into the high-speed disperser in turn, After dispersing each component into a uniform liquid at a ...

Embodiment 2

[0031] An epoxy adhesive for preparing an assembled prefabricated wallboard mold, the composition of the epoxy adhesive includes the following raw materials in parts by weight: 40 parts of bisphenol A epoxy resin E51, 5 parts of glycidyl ether, defoamer 0.3 parts, 0.1 parts of coupling agent, 60 parts of active silica powder, 5 parts of aluminum hydroxide, 40 parts of 4' diaminodiphenylmethane, 20 parts of propylene carbonate, 20 parts of Mannisamine, 10 parts of polyamide, dilaurel 0.1 part of dibutyltin acid and 0.5 part of thixotropic agent.

[0032] The preparation method of the epoxy adhesive for the preparation of the assembled prefabricated wallboard mold comprises the following steps:

[0033] (1) Weigh the raw materials of component A in sequence according to the number of parts by mass: bisphenol A epoxy resin E51, glycidyl ether, defoamer, coupling agent, and add each component into the high-speed disperser in turn, at 800r After dispersing each component into a un...

Embodiment 3

[0037] An epoxy adhesive for preparing an assembled prefabricated wallboard mold, the composition of the epoxy adhesive includes the following raw materials in parts by weight: 37 parts of bisphenol A epoxy resin E51, 10 parts of glycidyl ether, defoamer 0.1 parts, 0.2 parts of coupling agent, 55 parts of active silica powder, 10 parts of aluminum hydroxide, 35 parts of 4' diaminodiphenylmethane, 30 parts of propylene carbonate, 10 parts of mannisamine, 30 parts of polyamide, dilaurel 0.1 part of dibutyltin acid and 0.5 part of thixotropic agent.

[0038] The preparation method of the epoxy adhesive for the preparation of the assembled prefabricated wallboard mold comprises the following steps:

[0039] (1) Weigh the raw materials of component A in sequence according to the number of parts by mass: bisphenol A epoxy resin E51, glycidyl ether, defoamer, coupling agent, and add each component into the high-speed disperser in turn, at 700r After dispersing each component into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com