Modified phenolic resin material and preparation method thereof

A technology for modification of phenolic resin, applied in the field of modified phenolic resin materials and their preparation, can solve the problems of improving the toughness of phenolic resin materials, and achieve the effects of improving toughness, improving impact strength and heat resistance, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

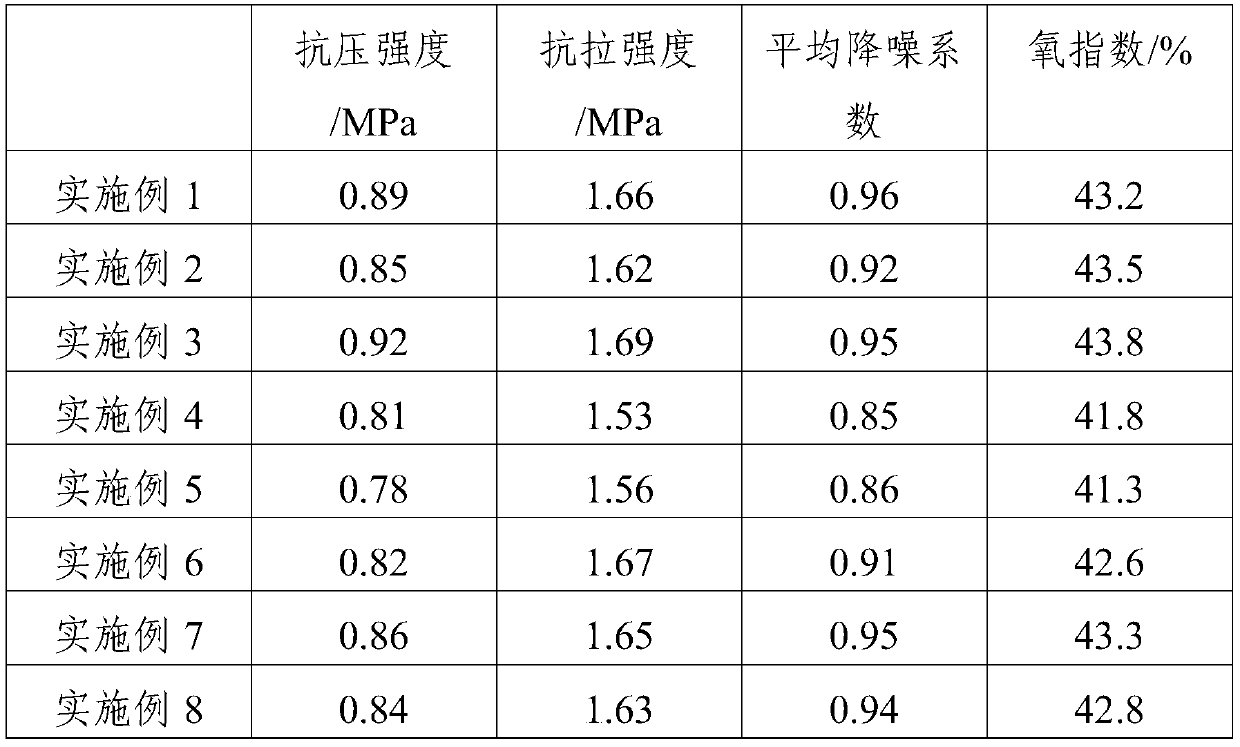

Examples

Embodiment 1

[0029] A modified phenolic resin material, comprising the following raw materials in parts by weight: 100 parts of cashew nut shell oil modified phenolic resin, 15 parts of hydroxyl-terminated liquid polybutadiene rubber, SiO 2 6 parts of coated carbon fiber, 2 parts of silicon powder, 0.6 part of silane coupling agent KH550, 7 parts of n-pentane, 0.5 part of 2,6-di-tert-butyl-4-methylphenol, 6 parts of hexamethylenetetramine .

[0030] Cashew nut shell oil modified phenolic resin is prepared by the following method: add cashew nut shell oil, phenol and sodium hydroxide into the reactor, stir evenly, add formaldehyde solution while stirring, and control the system temperature between 60-65 °C After the formaldehyde solution is added, the temperature is raised to 80-85°C for 2 hours, and then the temperature is raised to 100-105°C for 1.5 hours; after the reaction, dehydration is carried out to obtain cashew nut shell oil modified phenolic resin. Among them, the molar ratio of...

Embodiment 2

[0033] A modified phenolic resin material, comprising the following raw materials in parts by weight: 100 parts of cashew nut shell oil modified phenolic resin, 18 parts of hydroxyl-terminated liquid polybutadiene rubber, SiO 2 4 parts of coated carbon fiber, 2 parts of zirconia, 0.7 parts of silane coupling agent KH560, 8 parts of n-pentane, 0.5 parts of 2,6-di-tert-butyl-4-methylphenol, 5 parts of hexamethylenetetramine .

[0034]Cashew nut shell oil modified phenolic resin is prepared by the following method: add cashew nut shell oil, phenol and sodium hydroxide into the reactor, stir evenly, add formaldehyde solution while stirring, and control the system temperature between 60-65 °C After the formaldehyde solution is added, the temperature is raised to 80-85° C. for 1.5-2 hours, and then the temperature is raised to 110-115° C. for 1.5 hours; after the reaction is completed, dehydration is carried out to obtain cashew nut shell oil modified phenolic resin. Among them, th...

Embodiment 3

[0037] A modified phenolic resin material, comprising the following raw materials in parts by weight: 100 parts of cashew nut shell oil modified phenolic resin, 20 parts of hydroxyl-terminated liquid polybutadiene rubber, SiO 2 8 parts of coated carbon fiber, 2 parts of zirconia, 0.8 parts of silane coupling agent KH570, 8 parts of n-pentane, 0.6 parts of 2,6-di-tert-butyl-4-methylphenol, 5 parts of hexamethylenetetramine .

[0038] Cashew nut shell oil modified phenolic resin is prepared by the following method: add cashew nut shell oil, phenol and sodium hydroxide into the reactor, stir evenly, add formaldehyde solution while stirring, and control the system temperature between 65-70°C After the formaldehyde solution is added, the temperature is raised to 85-90°C for 1.5h, and then the temperature is raised to 110-115°C for 1h; after the reaction, dehydration is carried out to obtain cashew nut shell oil modified phenolic resin. Among them, the molar ratio of cashew nut she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com