Spraying-free high-transparent high-glossy acrylonitrile butadiene styrene (ABS) material and preparation method thereof

An ABS material and spray-free technology, which is applied in the field of ABS alloy materials, can solve the problems of increasing cost price, waste, and restricting the use of materials, and achieve the effects of improving color saturation, reducing production costs, and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

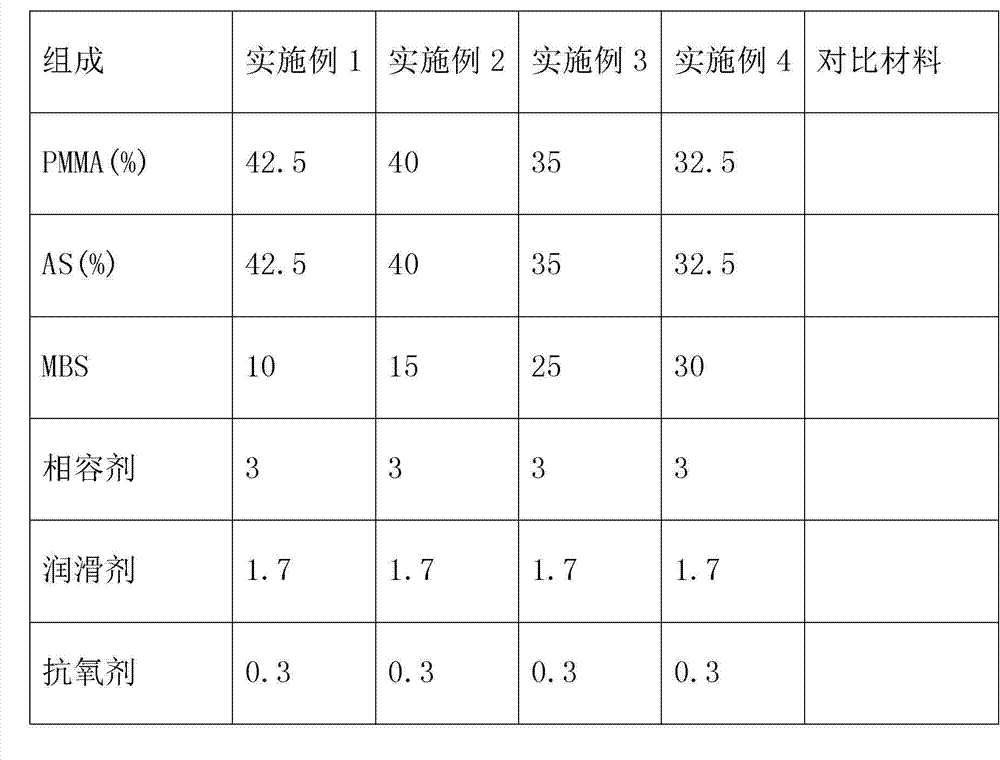

Embodiment 1

[0034] The weight percentage PMMA (CM205) 42.5%, AS (DN50) 42.5%, MBS (EXL-2668) 10%, compatibilizer (L-5330) 3%, lubricant (EBS) 1.7%, antioxidant-1010 The percentage content is 0.3%. The mixed materials are put into the hopper of the twin-screw extruder, melted, mixed and extruded, extruded and granulated into alloy materials. Among them, the twin-screw processing technology is: the processing technology is as follows: Twin-screw extruder zone 190-220 ° C, zone 2 200-220 ° C, zone 3 temperature 200-220 ° C, zone 4 200-220 ° C, zone 5 200- 220°C, 200-220°C in the sixth zone, 200-220°C in the seventh zone, 200-220°C in the eighth zone, 200-220°C in the ninth zone, 200-210°C in the machine head, the material stays in the barrel for 1-2min, and then After pelletizing and drying, a spray-free, high-gloss transparent ABS alloy material is obtained.

Embodiment 2

[0036] The weight percentage PMMA (CM205) 40%, AS (DN50) 40%, MBS (EXL-2668) 15%, compatibilizer (L-5330) 3%, lubricant (EBS) 1.7%, antioxidant-1010 The percentage is 0.3%. The mixed materials are put into the hopper of the twin-screw extruder, melted, mixed and extruded, extruded and granulated into alloy materials. Among them, the twin-screw processing technology is: the processing technology is as follows: Twin-screw extruder zone 190-220 ° C, zone 2 200-220 ° C, zone 3 temperature 200-220 ° C, zone 4 200-220 ° C, zone 5 200- 220°C, 200-220°C in the sixth zone, 200-220°C in the seventh zone, 200-220°C in the eighth zone, 200-220°C in the ninth zone, 200-210°C in the machine head, the material stays in the barrel for 1-2min, and then After pelletizing and drying, a spray-free, high-gloss transparent ABS alloy material is obtained.

Embodiment 3

[0038] The weight percentage PMMA (CM205) 35%, AS (DN50) 35%, MBS (EXL-2668) 25%, compatibilizer (L-5330) 3%, lubricant (EBS) 1.7%, antioxidant-1010 The percentage is 0.3%. The mixed materials are put into the hopper of the twin-screw extruder, melted, mixed and extruded, extruded and granulated into alloy materials. Among them, the twin-screw processing technology is: the processing technology is as follows: Twin-screw extruder zone 190-220 ° C, zone 2 200-220 ° C, zone 3 temperature 200-220 ° C, zone 4 200-220 ° C, zone 5 200- 220°C, six zones 200-220°C, seven zones 200-220°C, eight zones 200-220°C, nine zones 200-220°C head 200-210°C, the material stays in the barrel for 1-2min, and then passes through After dicing and drying, a spray-free, high-gloss transparent ABS alloy material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com