High-light-shielding high-impact-resistance PC/PBT alloy material and preparation method thereof

An alloy material and high-impact technology, which is applied in the field of high light-shielding and high-impact PC/PBT alloy materials and their preparation, can solve the problems of high notch sensitivity, limited application range, and low notch impact strength, and achieve cost reduction, Effects of improving mechanical properties and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Simultaneously, the present invention also provides a kind of preparation method of PC / PBT alloy material with high shading and high impact resistance, and described preparation method comprises the following steps:

[0042] 1) According to the proportion, add the polycarbonate, polybutylene terephthalate and coupling agent into the stirring tank, stir at the speed of 800-1000 rpm for 10-15 minutes, and mix well;

[0043] 2) Add the compatibilizer, transesterification inhibitor, antioxidant and light stabilizer into the stirring tank according to the proportion, stir at a speed of 1200-1400 rpm for 20-30 minutes, and mix well;

[0044] 3) adding the inorganic filler into the stirring tank according to the proportion, stirring at a speed of 800-1000 rpm for 5-10 minutes, and mixing evenly to obtain a mixed material;

[0045]4) Put the mixed material into a twin-screw extruder, control the barrel temperature of the twin-screw extruder at 230-260° C., extrude and pelletize...

Embodiment 1

[0051] The high light-shielding high-impact PC / PBT alloy material includes the following components by weight:

[0052] Polycarbonate: 35 parts, polybutylene terephthalate: 20 parts, inorganic filler: 13 parts, compatibilizer: 7 parts, transesterification inhibitor: 2 parts, antioxidant: 3 parts, photostable Agent: 4 parts, coupling agent: 3 parts.

[0053] The performance parameters of the prepared high light-shielding and high-impact PC / PBT alloy material are shown in Table 2.

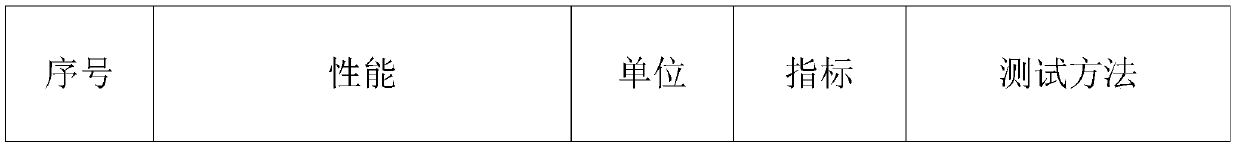

[0054] Table 2

[0055]

[0056]

Embodiment 2

[0058] The high light-shielding high-impact PC / PBT alloy material includes the following components by weight:

[0059] Polycarbonate: 40 parts, polybutylene terephthalate: 15 parts, inorganic filler: 15 parts, compatibilizer: 5 parts, transesterification inhibitor: 5 parts, antioxidant: 1 part, photostable Agent: 1 part, coupling agent: 5 parts.

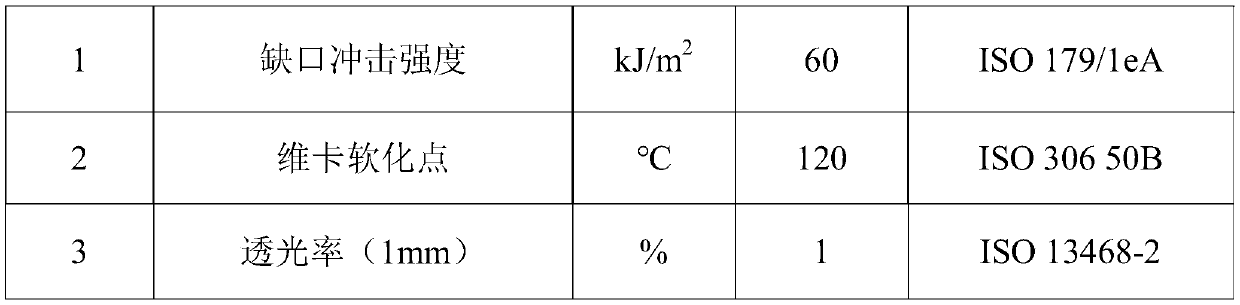

[0060] The performance parameters of the prepared high light-shielding and high-impact PC / PBT alloy material are shown in Table 3.

[0061] table 3

[0062] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com