Transparent flame-retardant MPPO resin composition and preparation method thereof

A resin composition and transparent technology, applied in the field of materials, can solve problems such as opacity, and achieve the effects of stable flame retardancy, reducing addition amount, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

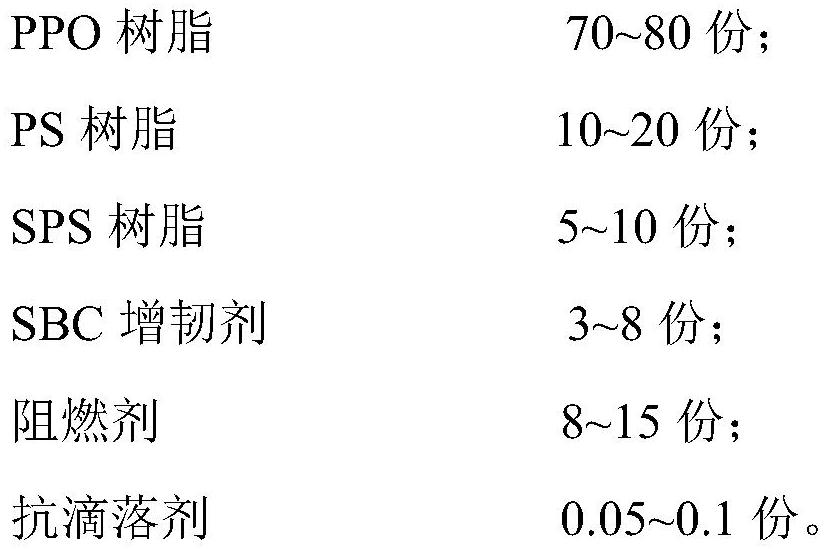

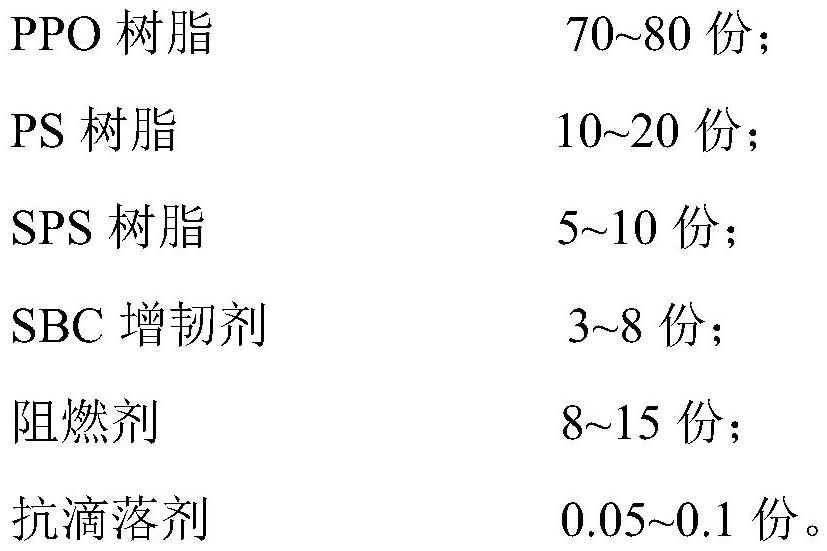

Method used

Image

Examples

Embodiment 1-6

[0054] Embodiment 1-6 provides a kind of preparation method of transparent flame-retardant MPPO resin composition, and the method comprises the following steps:

[0055] According to the weight percentage of the formula ingredients in Table 1, the raw materials are added to the high-speed mixer and mixed thoroughly, and then placed in the screw machine, at the extrusion temperature of 220-250 ° C and the screw speed of 200-500 rpm. Melt extrusion, cooling and granulation to obtain the product.

[0056] Table 1 embodiment formula parts by weight and performance

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com