Renewable bio-based vinyl ester resin and preparation method thereof

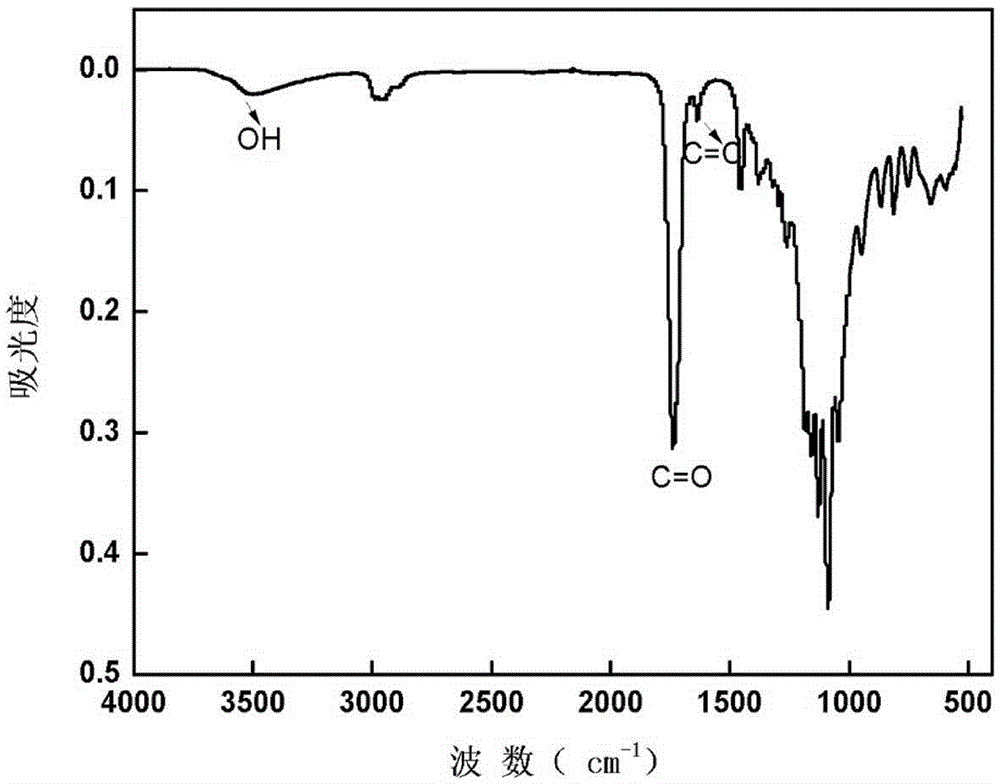

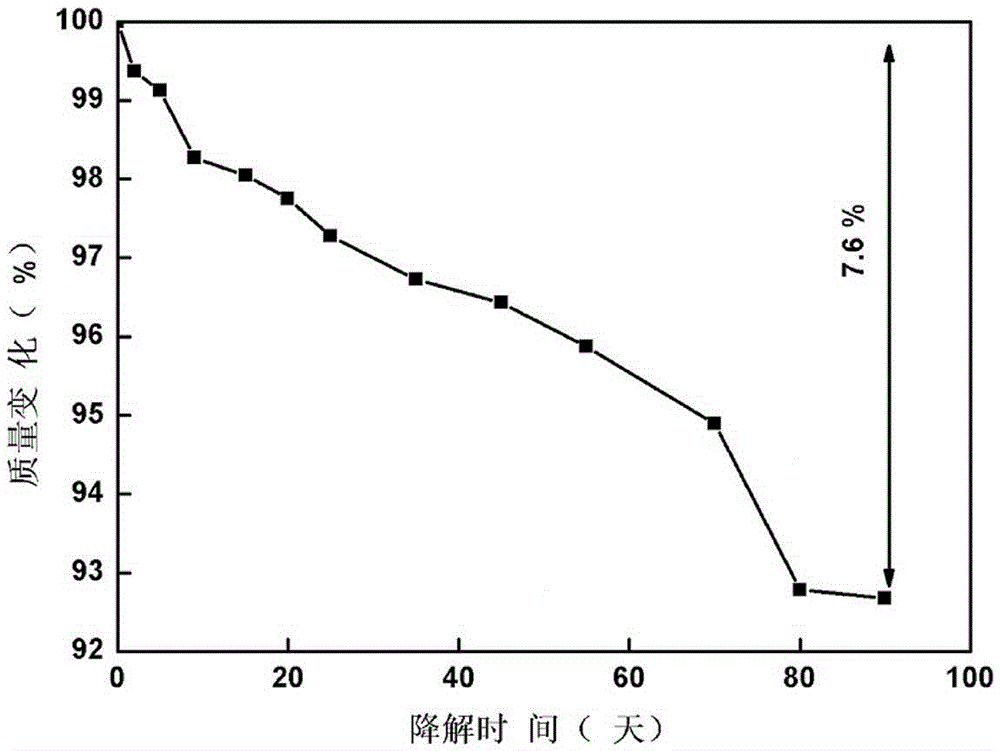

A kind of bio-based vinyl ester and biological technology, applied in the field of renewable bio-based vinyl ester resin and its preparation, can solve the problems of non-degradable thermosetting vinyl ester resin, high VOC emission, difficult recycling, etc., and achieve low shrinkage High efficiency, low VOC emission, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

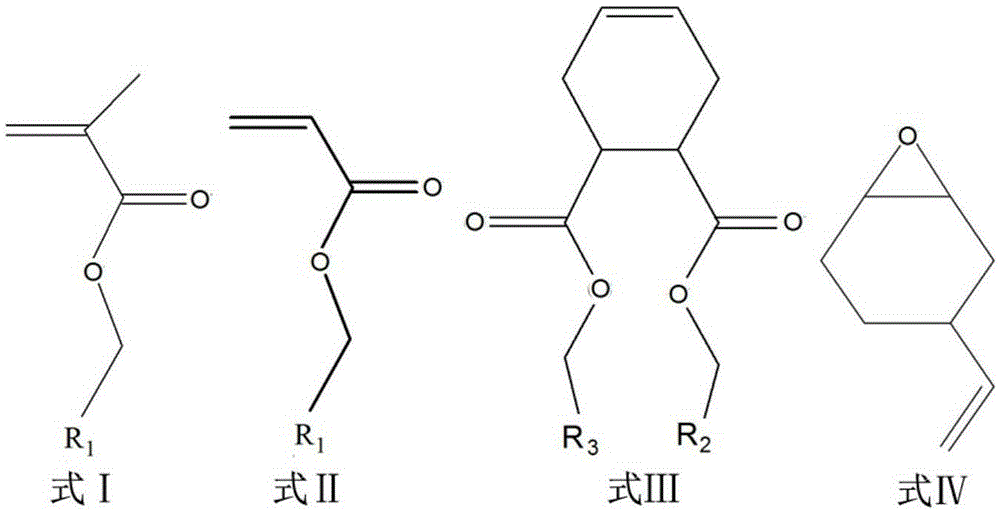

Embodiment 1

[0050] Take a certain amount of lactic acid in the reaction kettle, add succinic anhydride in a molar ratio of 0.05:1 to lactic acid, gradually raise the temperature to 130°C, and mix evenly with magnetic stirring, control the system pressure at 10 4 Under reduced pressure and reflux under Pa for 4h; slowly drop a certain amount of Sn(Oct) 2 (the addition amount is 0.15% of the mass of lactic acid), gradually warming up to 160°C, controlling the pressure inside the kettle to 500Pa, reflux reaction for 6h, cooling to obtain block oligomers, and adopting 0.1mol / L KOH-ethanol standard solution to measure the acid value , the measured value is 217mgKOH / g; weigh a certain amount of oligomers in the reaction bottle according to the mass ratio, heat up to 120°C to melt completely, and gradually cool down to 60°C; Slowly add glycidyl methacrylate dropwise at 0.275:1, then gradually raise the temperature to 70-80°C and stir evenly, react for 1-3.5 hours; add 0.10%, 0.01% tetramethylamm...

Embodiment 2

[0052] Take a certain amount of lactic acid in the reaction kettle, add succinic anhydride in a molar ratio of 0.12:1 to lactic acid, gradually raise the temperature to 130°C, and mix evenly with magnetic stirring, control the system pressure at 10 4 Under reduced pressure and reflux under Pa for 2h; slowly drop a certain mass of Sn(Oct) 2 (the addition amount is 0.30% of the lactic acid mass), gradually warming up to 150°C, controlling the pressure in the kettle to 500Pa, reflux reaction for 8h, and cooling to obtain the intermediate block oligomer; adopt 0.1mol / L KOH-ethanol standard solution to measure Acid value, the measured value is 395mgKOH / g; weigh a certain amount of oligomers in the reaction bottle according to the mass ratio, heat up to 120°C to melt completely, and gradually cool down to 60°C; Slowly add glycidyl methacrylate dropwise at a mass ratio of 0.57:1, then gradually raise the temperature to 70-80°C and stir evenly, react for 1-3.5 hours; add 0.15%, 0.01% ...

Embodiment 3

[0054] Take a certain amount of lactic acid in a reaction kettle, add succinic anhydride in a molar ratio of 0.0245:1 to lactic acid, gradually raise the temperature to 130°C, and mix evenly with magnetic stirring, control the system pressure at 10 4 Under reduced pressure and reflux under Pa for 4h; slowly drop a certain mass of Sn(Oct) 2 (the addition amount is 0.15% of the mass of lactic acid), gradually warming up to 160°C, controlling the pressure in the kettle to 500Pa, refluxing for 6h, cooling to obtain the intermediate block oligomer; adopting 0.1mol / L KOH-ethanol standard solution for determination Acid value, the measured value is 205mgKOH / g; Weigh a certain amount of oligomers in the reaction bottle according to the mass ratio, heat up to 120°C to melt completely, and gradually cool down to 60°C; Slowly add glycidyl methacrylate at a mass ratio of 0.26:1, then gradually heat up to 70-80°C and stir evenly, react for 1-3.5 hours; add 0.35%, 0.01% triphenylphosphine a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com