Recycling process of waste polycarbonate

A polycarbonate and waste technology, which is applied in the field of recycling process of waste polycarbonate, can solve the problems such as the large drop in mechanical properties and the inability to effectively improve the comprehensive mechanical properties of polycarbonate recycled materials, so as to improve the mechanical properties, Improve toughness and comprehensive mechanical properties, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

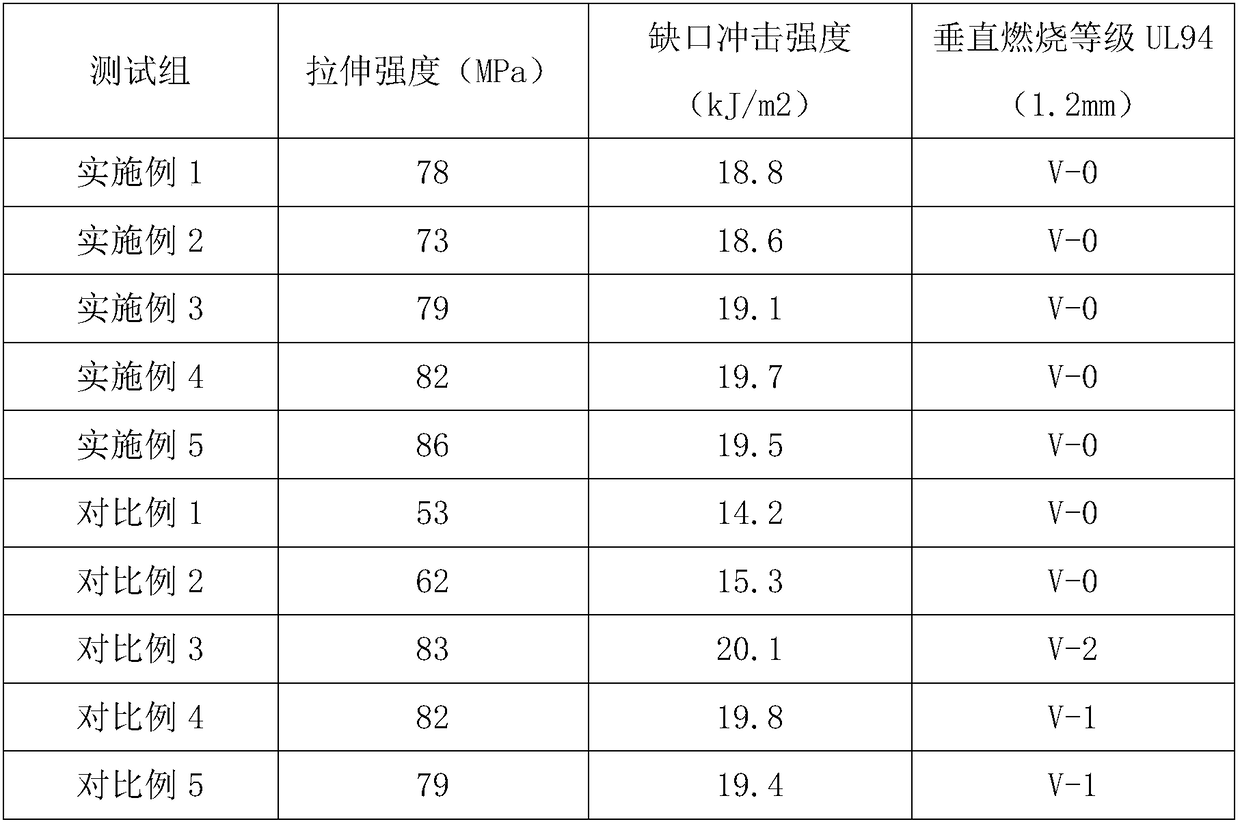

Examples

Embodiment 1

[0031] A recycling process for waste polycarbonate, comprising the following steps:

[0032] (1) The waste polycarbonate is crushed by a crusher until the particle size is less than 5 mm, and placed in an ultrasonic cleaning machine for cleaning for 15 minutes to obtain waste polycarbonate particles;

[0033] (2) Place the waste polycarbonate pellets in an oven at 80 degrees Celsius, after drying for 5 hours, add them to a twin-screw extruder for melt extrusion, cool and pelletize, and obtain polycarbonate pellets;

[0034] (3) Add maleic anhydride and triallyl cyanurate to acetone to dissolve, add polycarbonate and initiator to a high-speed mixer, mix for 20 minutes at 50 degrees Celsius, and add twin-screw extrusion Machine melting, cooling and pelletizing, the pellets were washed 3 times with deionized water, placed in an oven at 80 degrees Celsius, and dried for 15 hours to obtain modified polycarbonate pellets;

[0035] The mass ratio of maleic anhydride, triallyl cyanur...

Embodiment 2

[0047] A recycling process for waste polycarbonate, comprising the following steps:

[0048] (1) The waste polycarbonate is crushed by a crusher until the particle size is less than 5 mm, and placed in an ultrasonic cleaning machine for cleaning for 20 minutes to obtain waste polycarbonate particles;

[0049] (2) Place the waste polycarbonate granules in an oven at 90 degrees Celsius, after drying for 5 hours, add them to a twin-screw extruder for melt extrusion, cool and pelletize, and obtain polycarbonate granules;

[0050] (3) Add maleic anhydride and triallyl cyanurate to acetone to dissolve, add polycarbonate and initiator to a high-speed mixer, mix for 25 minutes at 55 degrees Celsius, and add twin-screw extrusion Machine melting, cooling and pelletizing, the pellets were washed 3 times with deionized water, placed in an oven at 90 degrees Celsius, and dried for 15 hours to obtain modified polycarbonate pellets;

[0051] The mass ratio of maleic anhydride, triallyl cyan...

Embodiment 3

[0063] A recycling process for waste polycarbonate, comprising the following steps:

[0064] (1) The waste polycarbonate is crushed by a crusher until the particle size is less than 5 mm, and placed in an ultrasonic cleaning machine for cleaning for 18 minutes to obtain waste polycarbonate particles;

[0065] (2) Place the waste polycarbonate pellets in an oven at 84 degrees Celsius, after drying for 5 hours, add them to a twin-screw extruder for melt extrusion, cool and pelletize, and obtain polycarbonate pellets;

[0066] (3) Add maleic anhydride and triallyl cyanurate to acetone to dissolve, add polycarbonate and initiator to a high-speed mixer, mix for 24 minutes at 53 degrees Celsius, and add twin-screw extrusion Machine melting, cooling and pelletizing, the pellets were washed 3 times with deionized water, placed in an oven at 86 degrees Celsius, and dried for 15 hours to obtain modified polycarbonate pellets;

[0067] The mass ratio of maleic anhydride, triallyl cyanur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com