Self-toughened benzoxazine thermosetting resin and method for preparing same

A benzoxazine and thermosetting technology, which is applied in the field of self-toughening benzoxazine thermosetting resin and its preparation, can solve the problems of elastomer precipitation, high curing temperature, and poor compatibility, and achieve toughness improvement and reduction Effect of curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of the self-toughening benzoxazine thermosetting resin, comprising the following steps:

[0030] The aminomethylation reaction is carried out after mixing the decanediamine solution and the formaldehyde solution to obtain an aminomethylation reaction product system;

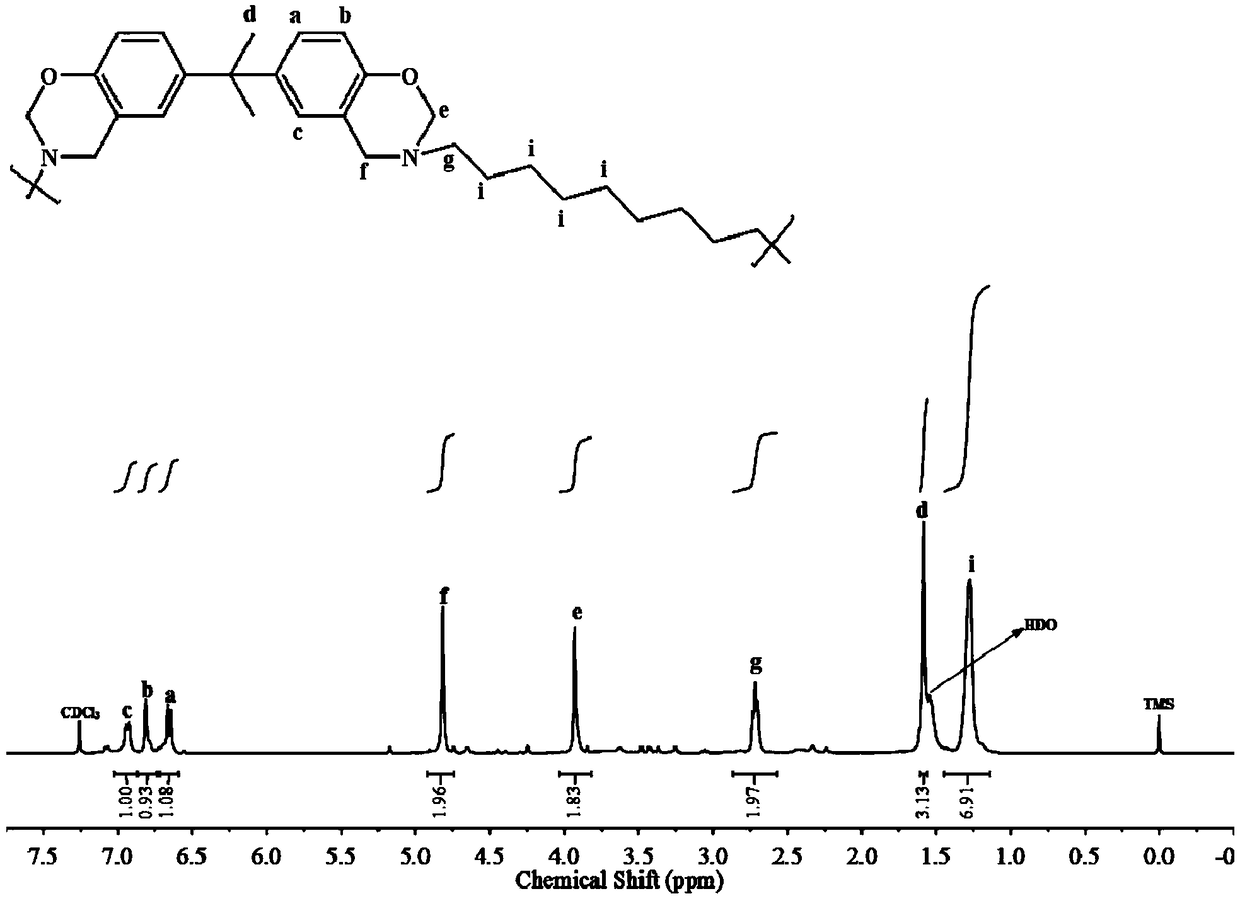

[0031] The aminomethylation reaction product system is mixed with bisphenol A and then subjected to Mannich reaction to obtain a self-toughening benzoxazine thermosetting resin having a structure shown in formula I.

[0032] In the present invention, the aminomethylation reaction is carried out after mixing the decanediamine solution and the formaldehyde solution to obtain an aminomethylation reaction product system. In the present invention, the molar ratio of decanediamine in the decanediamine solution to formaldehyde in the formaldehyde solution is preferably 1: (4-6).

[0033] In the present invention, the mass concentration of the decanediamine solution is ...

Embodiment 1

[0053] Dissolve bisphenol A in hot toluene at 50°C first, then allow it to cool and crystallize naturally, filter it with suction, and dry it for 12 hours at a relative vacuum degree of less than -0.085Mpa and a temperature of 60°C to obtain the first purified bisphenol A; Dissolve the obtained initially purified bisphenol A in hot 1,4-dioxane at 50°C, allow it to cool and crystallize naturally, filter it with suction, and put it under a relative vacuum less than -0.085Mpa at a temperature of Dry at 60°C for 12 hours, place the obtained bisphenol A in a desiccator for use;

[0054] According to the molar ratio of decanediamine to formaldehyde of 1:4, decanediamine was dissolved in 1,4-dioxane at 0°C to prepare 1,4-dioxane with a mass concentration of 5%. 4-dioxane solution, and the aqueous solution of formaldehyde with a mass concentration of 35% was added dropwise to the 1,4-dioxane solution of decanediamine in the form of dropwise addition. During the process, the temperatu...

Embodiment 2

[0060] Dissolve bisphenol A in hot toluene at 60°C first, then allow it to cool and crystallize naturally, filter it with suction, and dry it for 15 hours at a relative vacuum degree of less than -0.085Mpa and a temperature of 65°C to obtain the first purified bisphenol A; Dissolve the obtained initially purified bisphenol A in hot 1,4-dioxane at 55°C, allow it to cool and crystallize naturally, filter it with suction, and put it under a relative vacuum less than -0.085Mpa at a temperature of Dry at 65°C for 15 hours, place the obtained bisphenol A in a desiccator for use;

[0061] According to the molar ratio of decanediamine to formaldehyde of 1:4.5, decanediamine was dissolved in 1,4-dioxane at 2°C to prepare 1,4-dioxane with a mass concentration of 6%. 4-dioxane solution, and the aqueous solution of formaldehyde with a mass concentration of 37% was added dropwise in the 1,4-dioxane solution of decanediamine by means of dropwise addition. During the process, the temperatur...

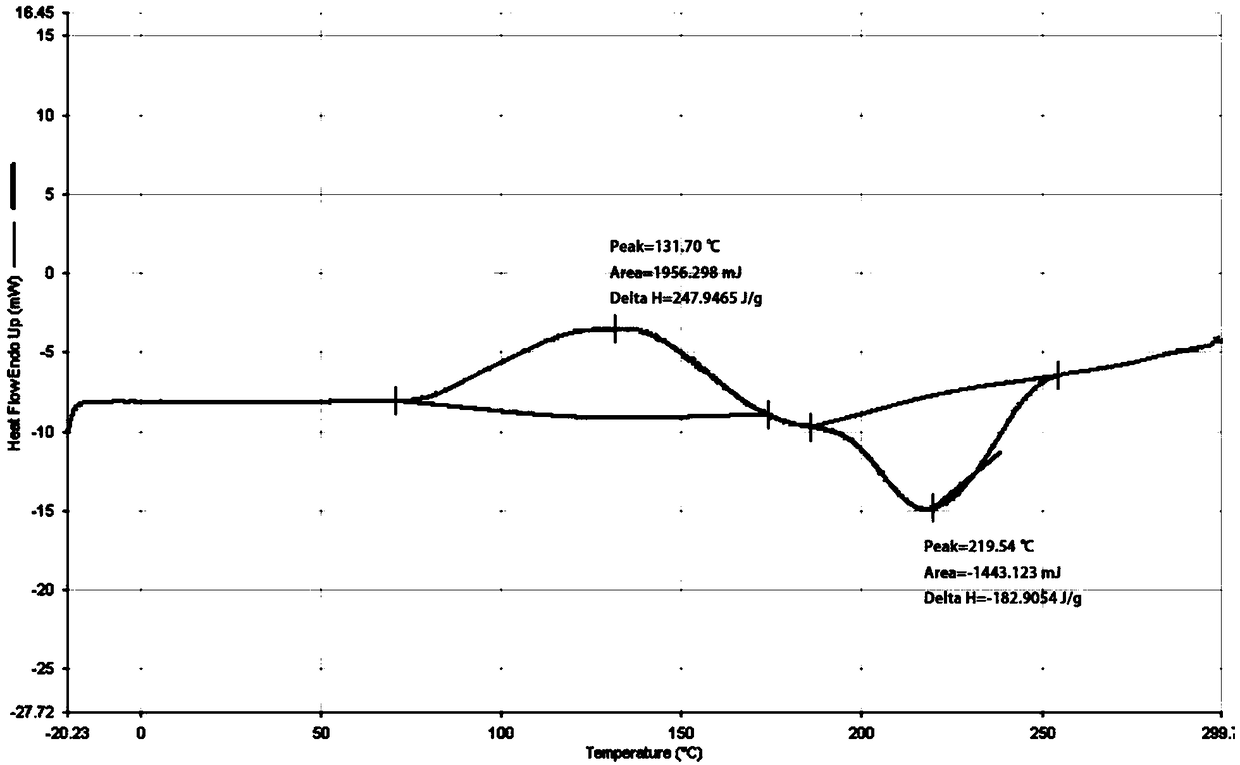

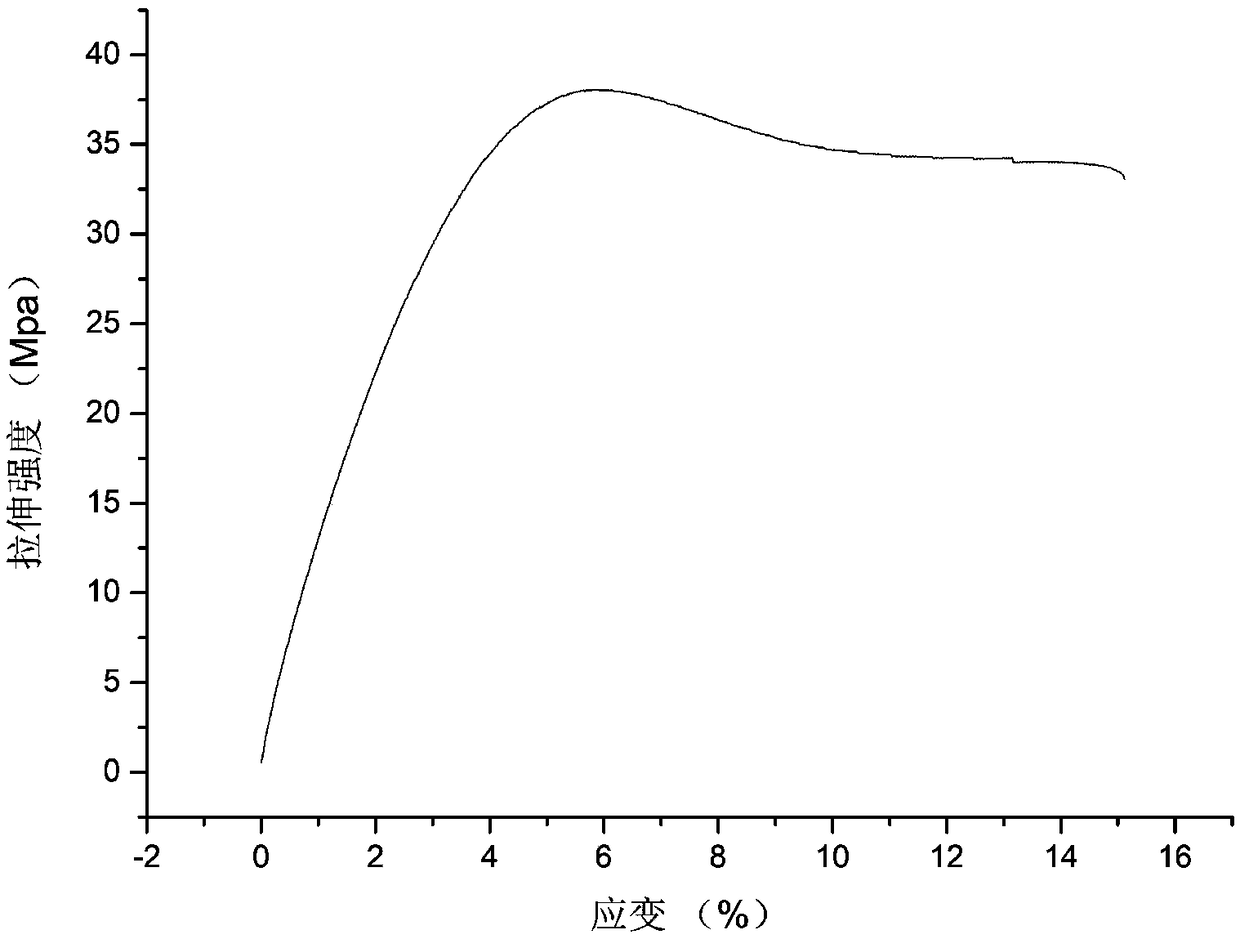

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curing start temperature | aaaaa | aaaaa |

| Peak temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com