Phenolic aldehyde insulation board for external wall and preparation method of phenolic aldehyde insulation board

A phenolic insulation board and exterior wall technology, which is applied in the field of building exterior wall materials, can solve the problems of high strength and oxygen index of insulation boards, high thermal conductivity and low thermal conductivity of phenolic foam boards, and achieves improved mechanical properties and good compatibility. , the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

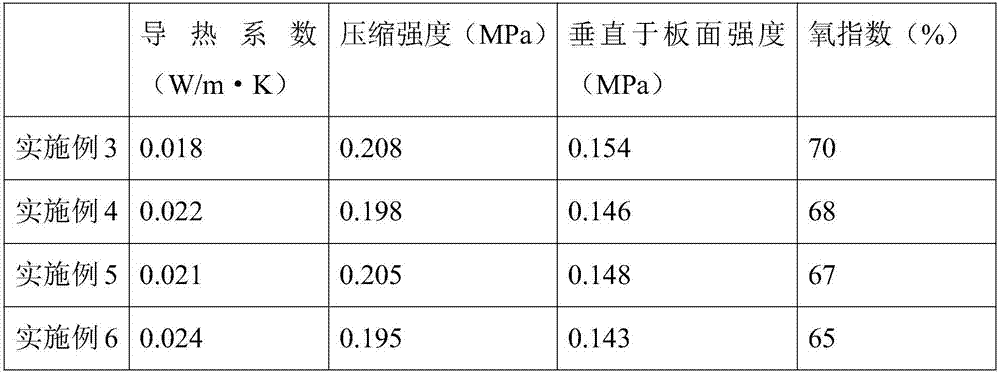

Examples

Embodiment 1

[0020] The preparation method of toughening agent is:

[0021] Dissolve 5 parts by weight of water glass and 5 parts by weight of sodium metaaluminate in 100 parts by weight of water to prepare a solution, then add 0.5 parts by weight of sodium lauryl sulfate to the solution, stir well, heat up to 70 ° C, add After reacting 10 parts by weight of polyethylene glycol for 2 hours, the solid substance obtained by rotary evaporation is the toughening agent.

Embodiment 2

[0023] The preparation method of toughening agent is:

[0024] Dissolve 8 parts by weight of water glass and 8 parts by weight of sodium metaaluminate in 100 parts by weight of water to prepare a solution, then add 1 part by weight of sodium hexadecylsulfonate to the solution, stir evenly, and heat up to 80°C. After adding 20 parts by weight of polyethylene glycol and reacting for 4 hours, the solid substance obtained by rotary evaporation is the toughening agent.

Embodiment 3

[0026] A phenolic insulation board for an exterior wall, calculated in parts by weight, comprising the following raw materials:

[0027] 70 parts of phenolic resins, 15 parts of polyether modified resins, 4 parts of plant fibers, 8 parts of blowing agents, 12 parts of p-toluenesulfonic acid and 4 parts of toughening agents in Example 1, blowing agents are ether, n-pentane and carbon dioxide mixture.

[0028] Preparation:

[0029] 1) Mix the phenolic resin, p-toluenesulfonic acid and the toughening agent of Example 1 uniformly at 50°C to obtain a mixture A;

[0030] 2) Mix and stir the mixture A, polyether modified resin, plant fiber and foaming agent evenly, quickly pour it into a mold preheated at 75°C for foaming, and then solidify.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com