Method for controlling lifting transverse moving mechanical parking equipment

A technology of lifting and moving type parking equipment, which is applied in the direction of buildings, building types, and buildings where cars are parked. It can solve the problems of large equipment control modules, complex control structures, and inconvenient construction and maintenance. It achieves fewer control modules and PLC Effect of cost reduction and total cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This embodiment is an example of application on a two-layer lifting and traversing parking equipment.

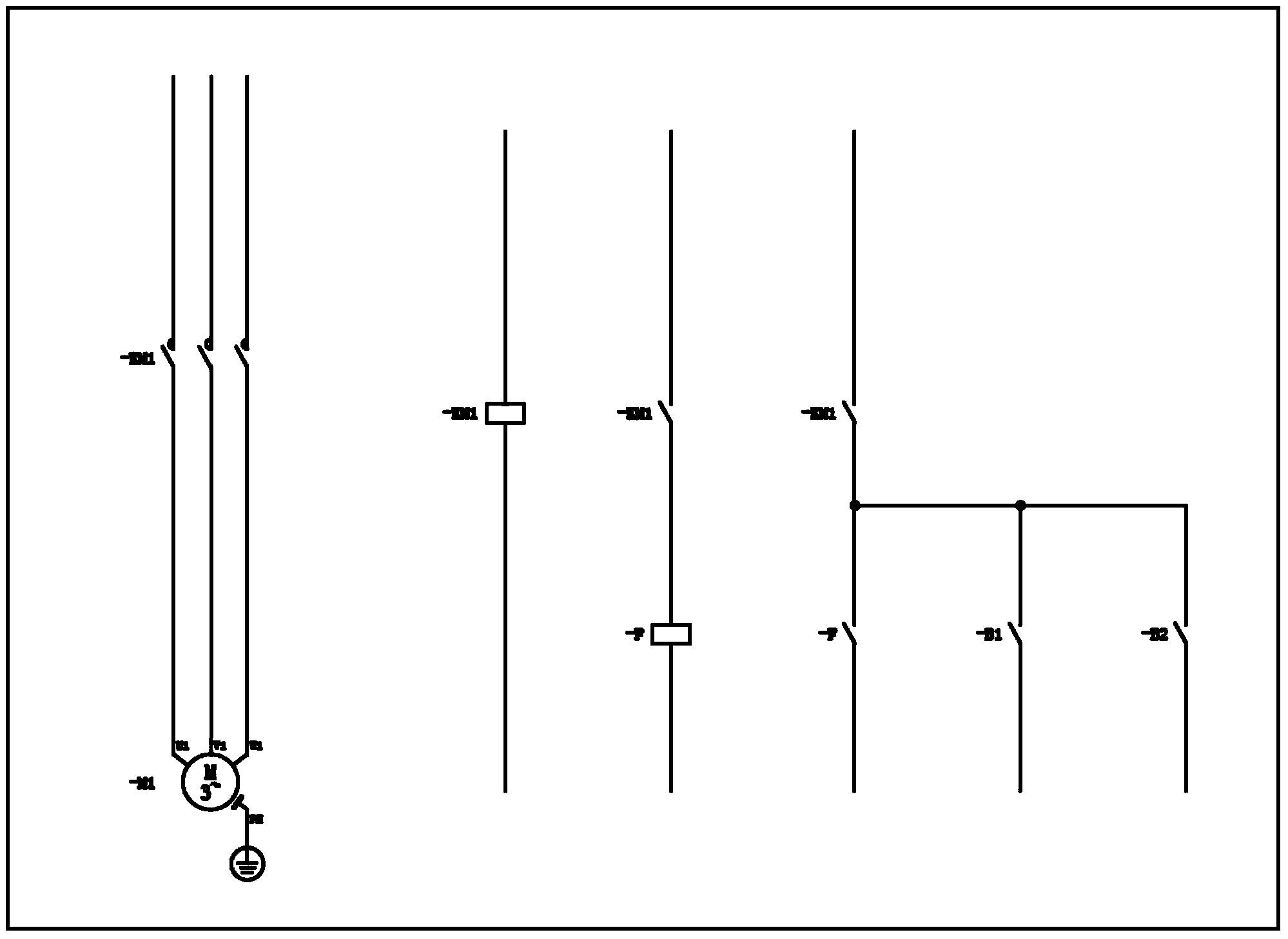

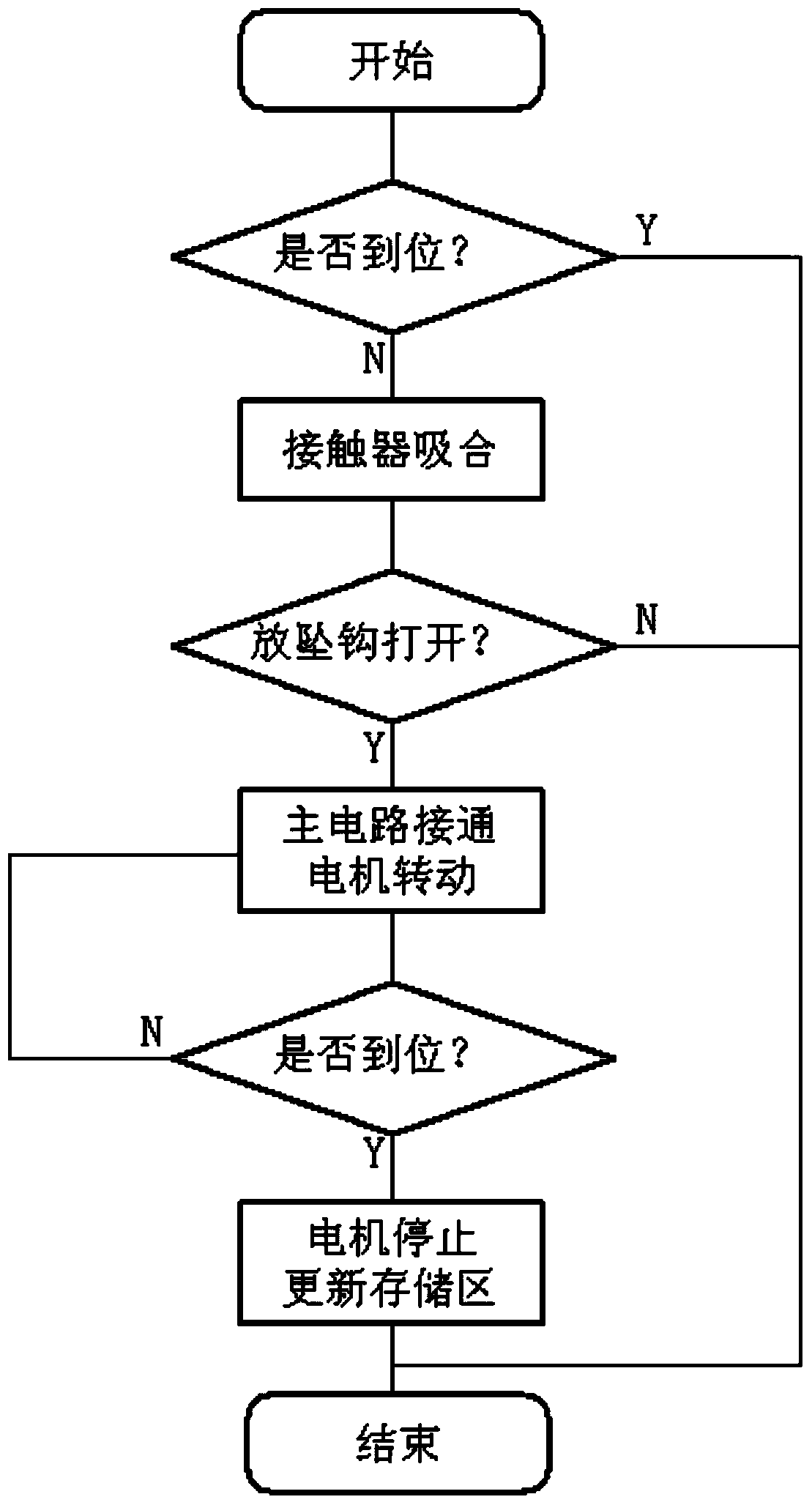

[0024] The control system of the two-story lift and traverse parking equipment adopts a modular structure, the PLC is placed in the control cabinet, and each row of lift parking spaces is a control module. There is a control box for each lifting parking space, which includes a second-level lifting contactor, a first-level traversing contactor and wiring terminals. The power supply and signal of each row of lifting spaces are connected to the PLC through the control box. The main components of each control module include a second-floor lifting motor and a first-floor traverse motor, a second-floor fall arrester, an upper limit switch and a lower limit switch, etc. figure 1 Schematic diagram of lift control. The two-layer in-position detection switch (upper in-position switch, lower in-position switch) and the power supply of the anti-dropping device are controlled by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com