Well bottom foaming foam drilling method

A foamed foam and drilling technology, which is applied in the field of foam drilling, can solve the problems of low return speed and low density of foam, and achieve the effect of reducing injection pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

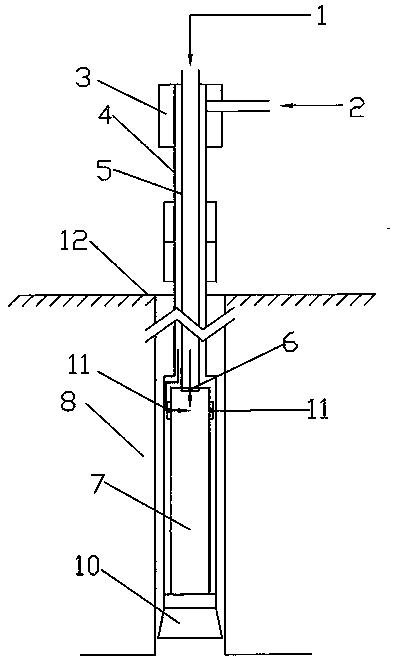

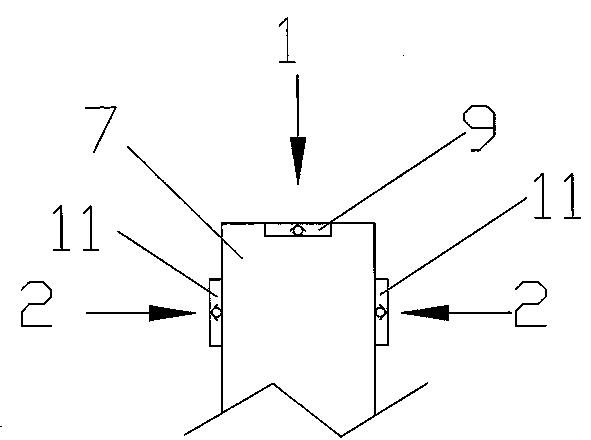

[0011] see figure 1 As shown, the present invention places the foam generator 9 used in conventional foam drilling on the bottom of the drill pipe, that is, the top of the drill bit 10. If it is for coring drilling, the foam generator 9 is placed on the top of the core pipe, so that the foam can be deposited at the bottom of the well. The ground equipment includes a foam liquid tank, a foam pump, an air compressor, and supporting pipelines. The foam liquid 2 sucked by the foam pump enters the ring of the inner wall 5 of the double-wall drill pipe and the outer wall 4 of the double-wall drill pipe through the double-channel air tap 3. Shaped space until the foam generator 7 at the bottom of the drill pipe; and the compressed air 1 enters the inner center channel 6 of the double-wall drill pipe through the double-channel air tap 3 until the foam generator 7; The foam is fully mixed in the medium to generate foam, and the generated foam can carry cuttings back to the surface 12 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com