Industrial cold and hot balance unit system and control method thereof

A technology for balancing units and industrial use, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., and can solve problems such as inability to cool, rational utilization of heat load, decline in equipment utilization, and inability to effectively save investment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

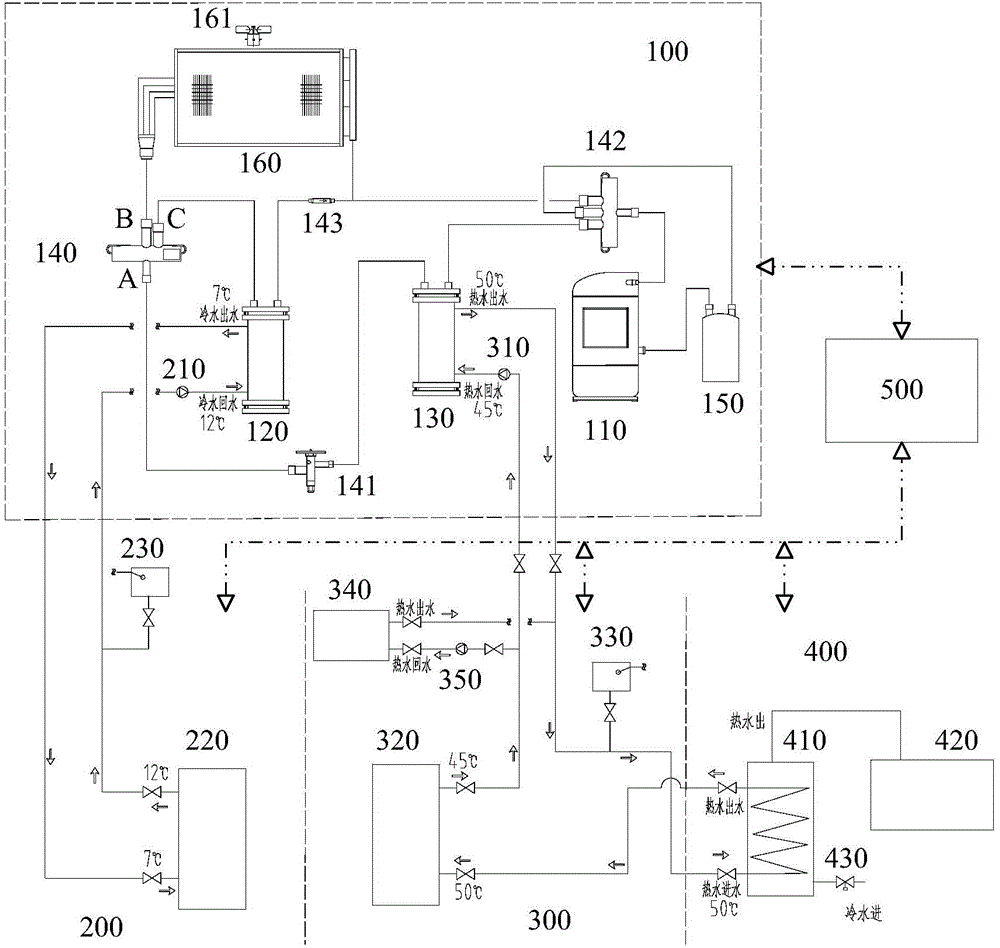

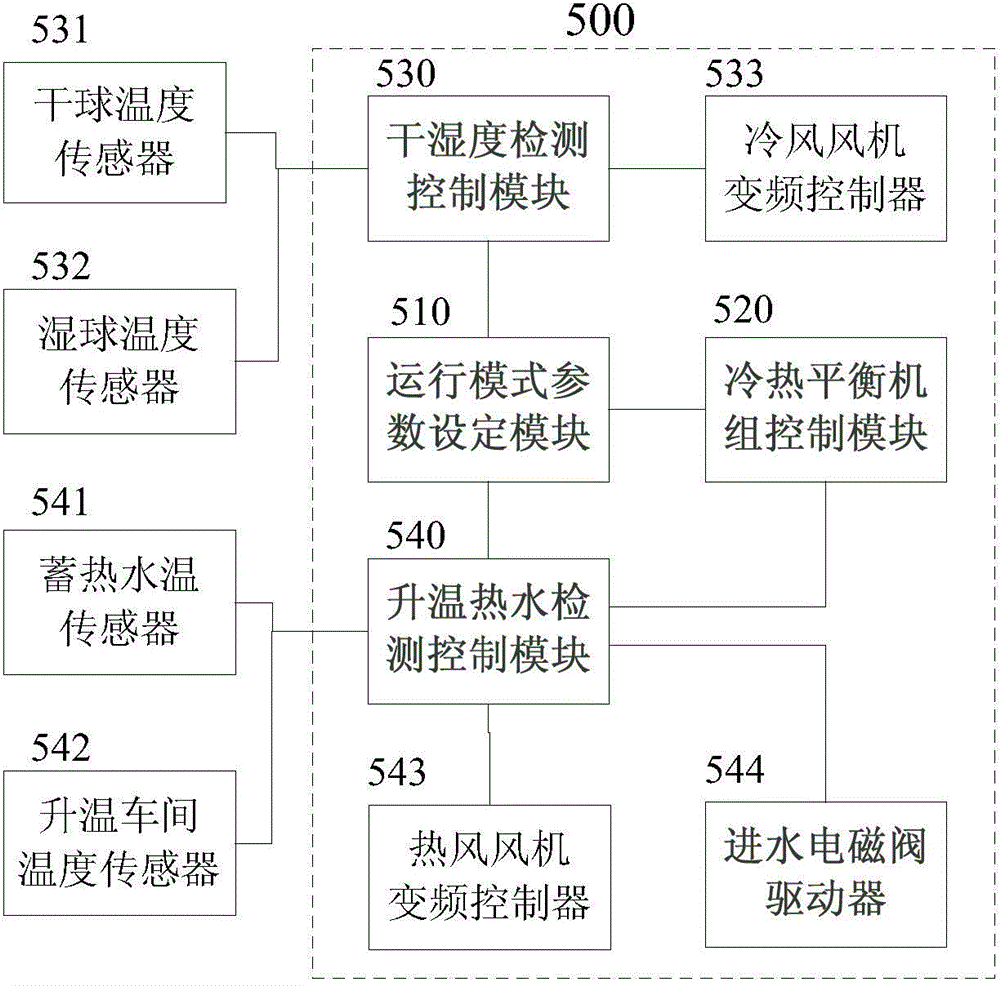

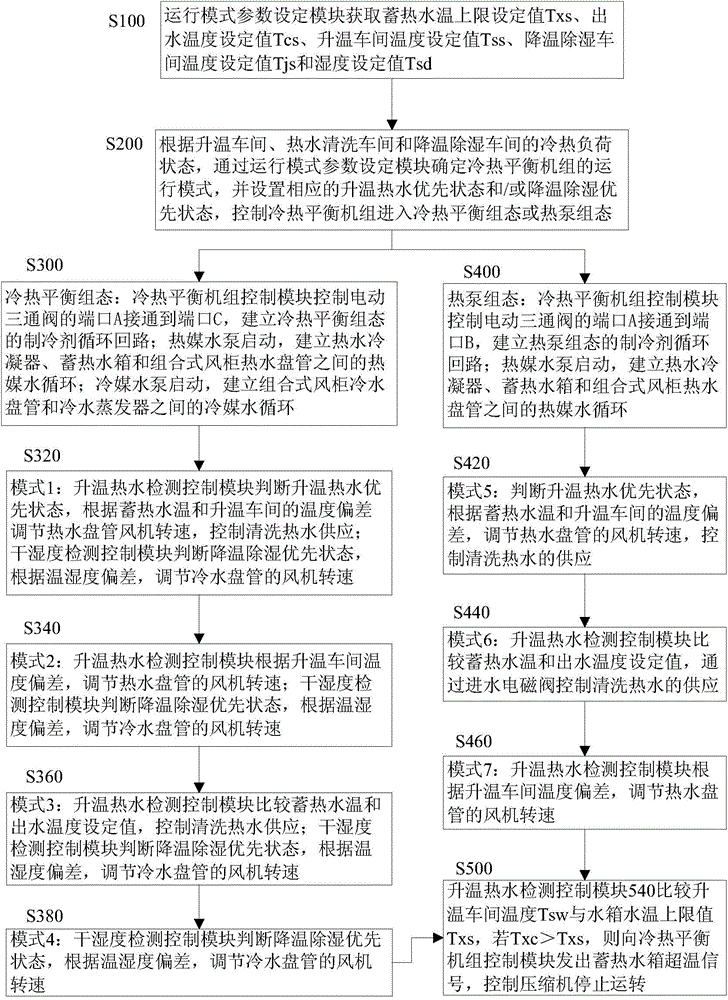

[0080] In order to better understand the above technical solutions of the present invention, the following further describes in detail with reference to the accompanying drawings and embodiments. figure 1 It is an embodiment of the industrial cold-heat balance unit system of the present invention used in the electronics industry, including a cold-heat balance unit 100, a cold air subsystem 200 that supplies cold air to the cooling and dehumidification workshop, and a hot air subsystem 300 that supplies hot air to the warming workshop. The hot water subsystem 400 for supplying hot water in the cleaning workshop and the control device 500; figure 1 In the illustrated embodiment, the cooling and heating balance unit 100 includes a refrigerant circulation circuit in a cooling and heating balance configuration and a refrigerant circulation circuit in a heat pump configuration; the control device 500 controls the cooling through an electric three-way valve 140 Configuration switching o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com