High-precision torque detection device

A torque detection, high-precision technology, applied in measuring devices, measuring torque/torsion force during tightening, calibration/testing of force/torque/power measuring instruments, etc., can solve chemical plant leakage explosions, wind turbine collapses, oil depots, etc. Leakage pollution and other issues to achieve the effect of ensuring stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

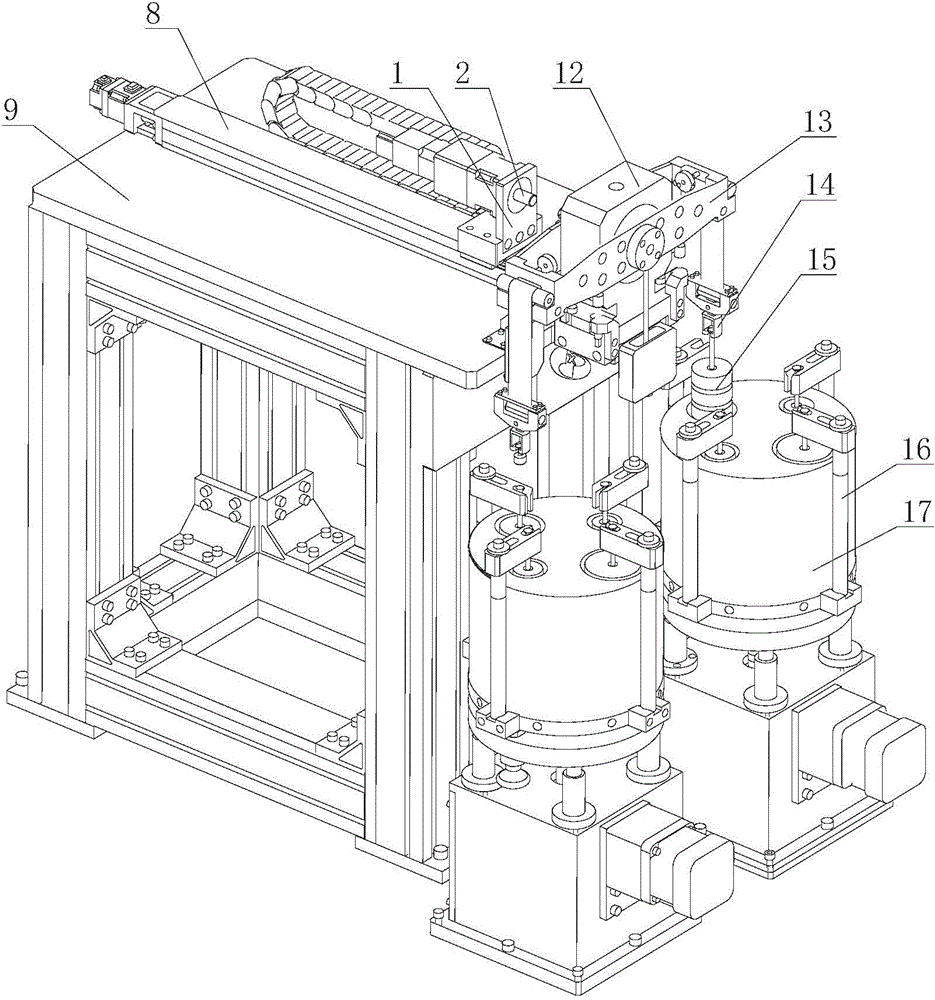

[0024] Such as Figure 1 to Figure 2 As shown, the first embodiment of the present invention provides a high-precision torque detection device, including a workbench 9, a guide rail seat 8, a weight fixing mechanism and a torque output mechanism, the guide rail seat 8 is fixedly arranged on the workbench 9, and the weight is fixed The mechanism includes a first fixing unit and a second fixing unit for fixing the two end faces of the tested product. The first fixing unit is fixedly arranged on the workbench 9 on the left side of the guide rail seat 8 in the length direction and is set between the guide rail seat 8 There is a gap, the second fixing unit is slidably arranged on the guide rail base 8 and slides back and forth along the length direction of the guide rail base 8, and the torque output mechanism is arranged under the first fixing unit.

[0025] In this embodiment, the first fixing unit and the second fixing unit fix the two end faces of the product to be tested to en...

Embodiment 2

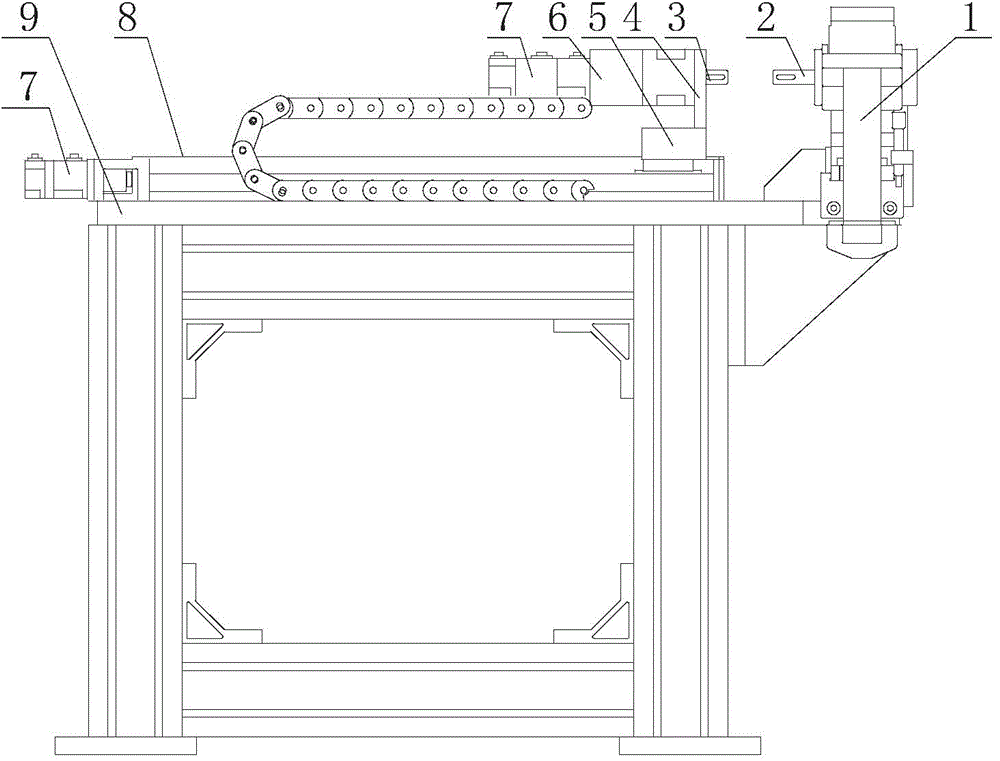

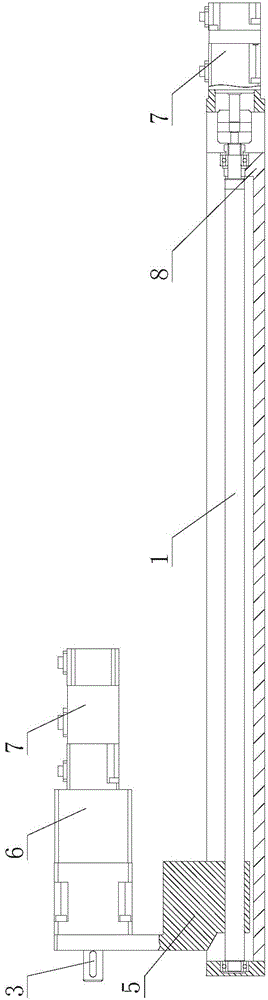

[0027] Such as Figure 3 to Figure 4 As shown, as the second preferred embodiment, the rest is the same as Embodiment 1, the difference is that the second fixing unit provided by this embodiment includes a slider 5, a second fixing frame 4 and a bracket for fixing the end face of the product under test. The second fixed shaft 3, the second fixed shaft 3 is arranged on the second fixed frame 4, the second fixed frame 4 is arranged on the slider 5, the slider 5 is slidably arranged on the ball screw 10, the second fixed shaft 3 and A motor 7 for driving the rotation of the second fixed shaft 3 is connected, and a reducer 6 is also arranged between the motor 7 and the second fixed shaft 3 .

[0028] The first fixing unit provided in this embodiment includes a first fixing frame 1, a first fixing shaft 2 and an air bearing 12 arranged on the first fixing frame 1. The first fixing frame 1 is fixedly arranged on the workbench 9. A fixed shaft 2 is arranged on the air bearing.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Straightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com