Permeability testing experimental method of reservoir core before and after hydraulic fracturing under triaxial stress condition

A core permeability and hydraulic fracturing technology, applied in the field of experimental systems, can solve the problems of inaccuracy, lack of hydraulic fracturing mechanism, application and development limitations, etc., and achieve the effect of improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

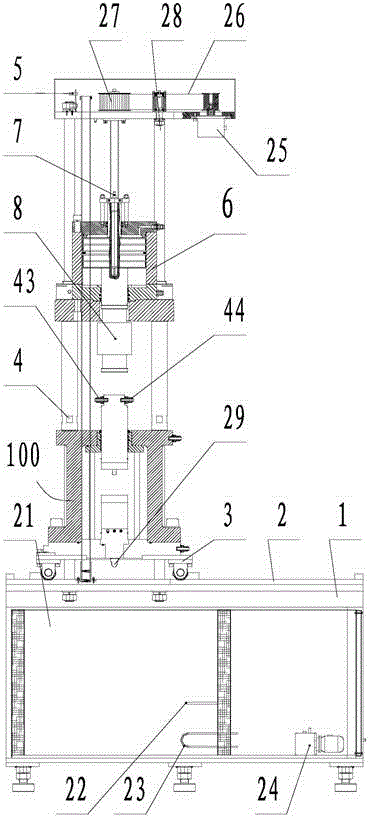

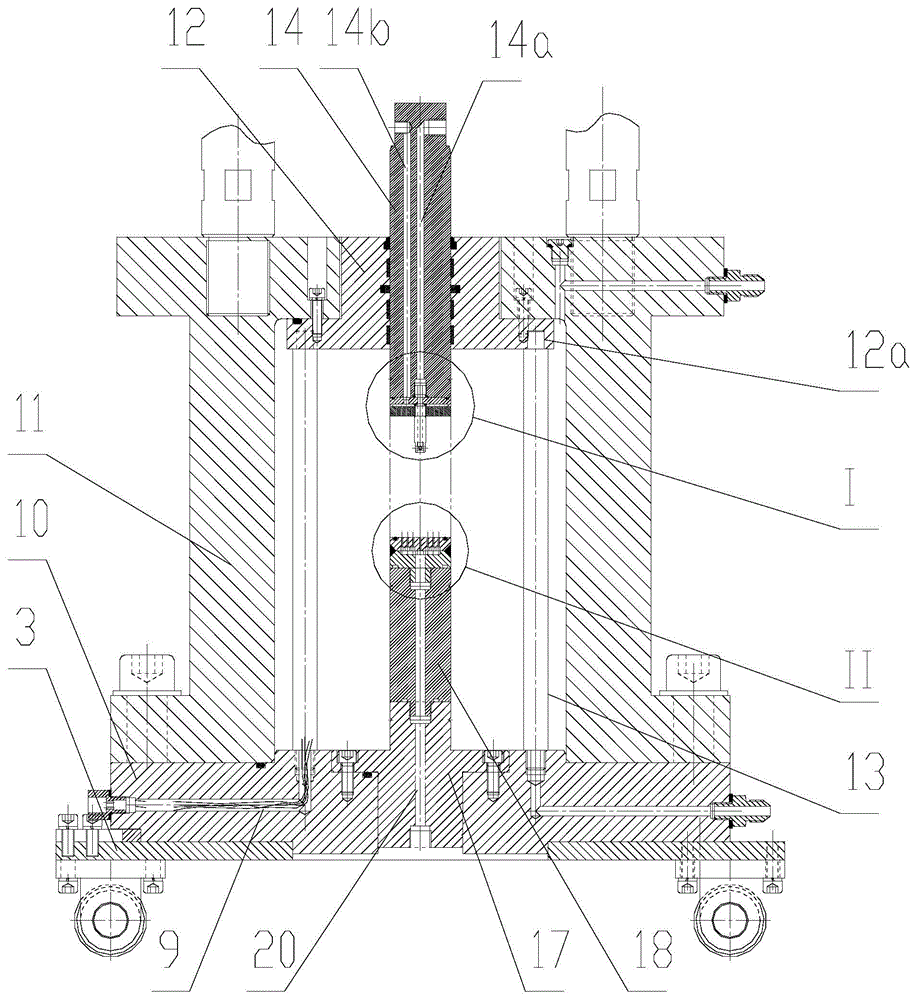

[0024] Such as Figure 1 to Figure 5 As shown, the completion of the method of the present invention must rely on a reservoir seepage medium thermo-fluid-solid coupling multiphase fluid fracturing-seepage experimental system, the system includes a frame 1, the lower part of the frame 1 is provided with parallel guide rails 2, parallel guide rails 2 Mobile dolly 3 is arranged on it.

[0025] The middle part of the frame 1 is fixed with an oil cylinder 6, a displacement sensor 7 is fixed on the piston 6a of the oil cylinder 6, and a pressure sensor 8 is fixed at the protruding end of the piston 6a.

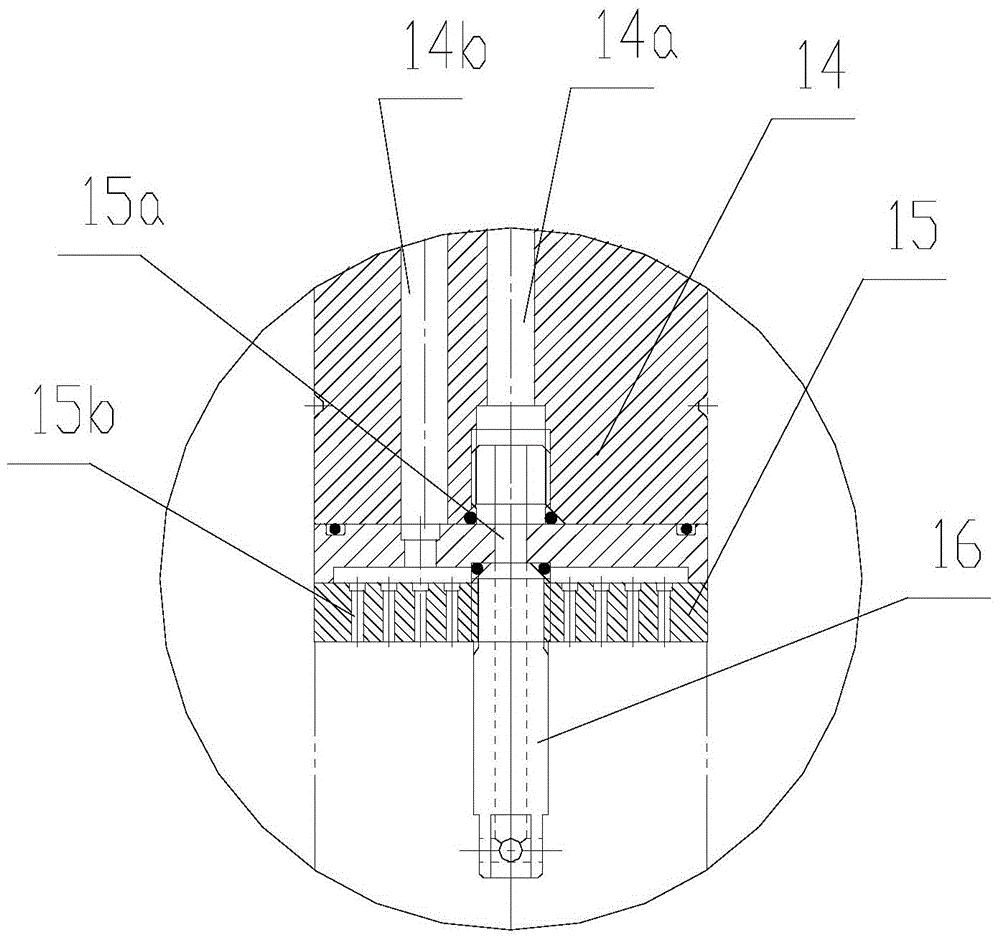

[0026] The bottom of frame 1 is provided with pressure chamber 100, and pressure chamber 100 comprises the bottom cover 10 that can be placed on mobile trolley 3, and bottom cover 10 is bolted with upper seat 11, and the upper end of upper seat 11 is fixed with gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com