Aerial oil receiving guide control method based on machine vision

A guidance control and machine vision technology, applied in the field of aviation flight control, can solve the problems of not meeting the accuracy requirements of automatic aerial refueling, increasing the pilot's manipulation burden, and low success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

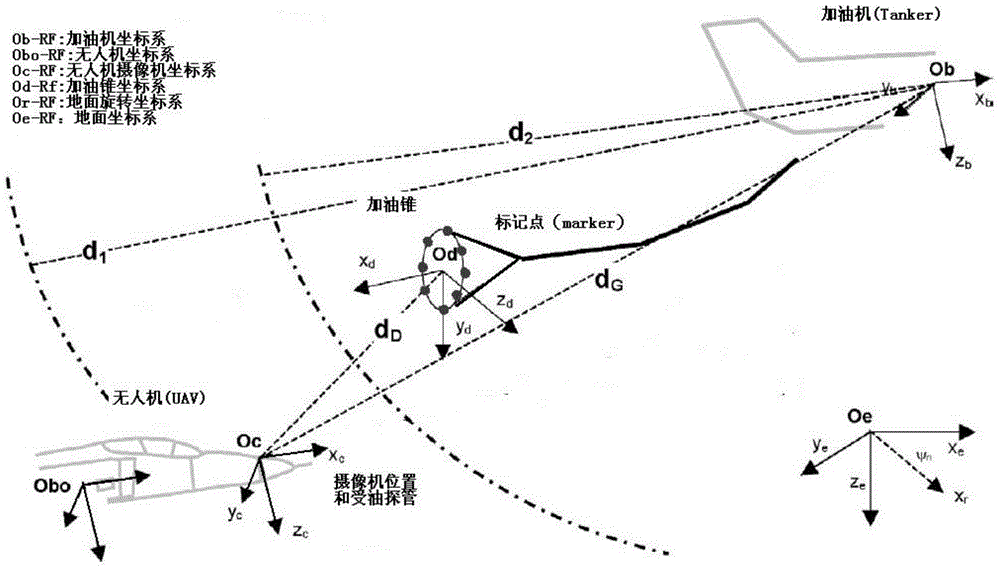

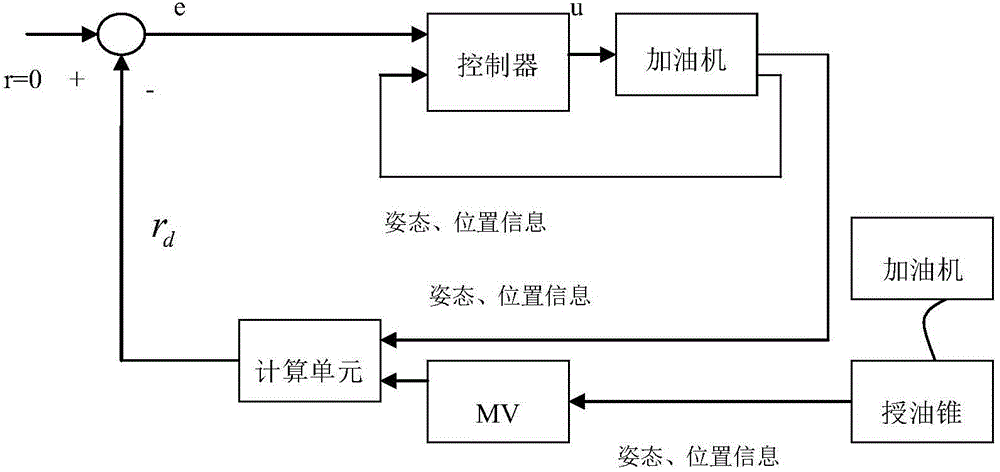

[0036] The present invention will be further described in detail below through specific control strategies in conjunction with the accompanying drawings.

[0037] Assuming that the fuel dispenser is flying straight and level at a constant height and constant speed, an auxiliary optical mark is installed on the fueling cone of the fuel dispenser, and a camera is installed on the fuel receiver.

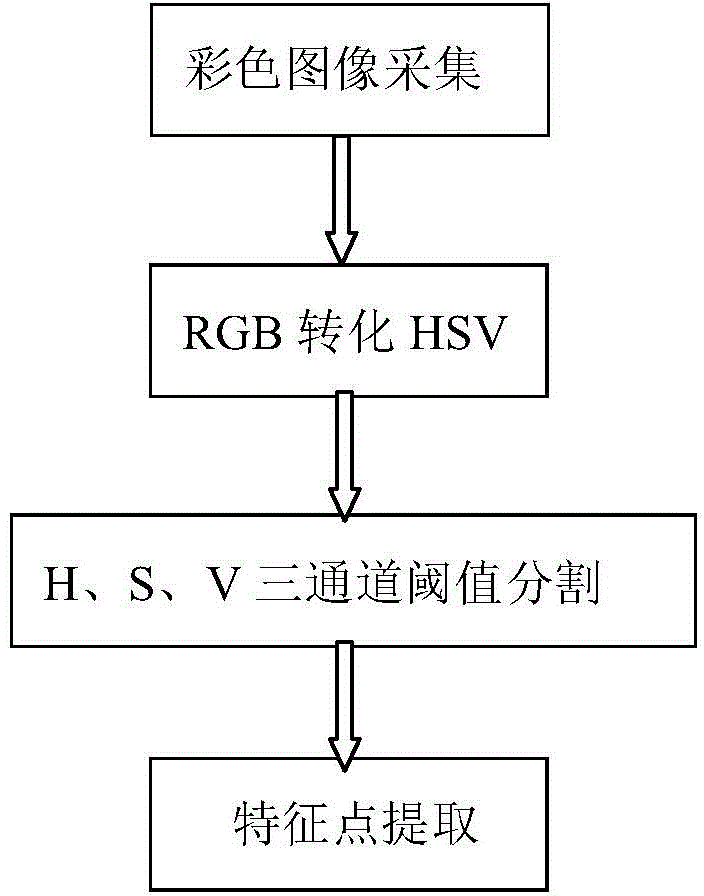

[0038] The first is to define the coordinate system where the fuel dispenser, receiver, fuel cone, and camera are located, and describe the geometric pose relationship through the transformation between each coordinate system. Set the relative distance of the visual fuel cone as: X=-1.4m, Y=0.5m, Z=5.6m, such as figure 1 Shown. Through the color space (RGB) to hue, saturation, and lightness (HSV) processing of the image collected by the camera, the images of the three channels of H, S, and V, and the H and S channel images are selected for the given threshold segmentation. The target point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com