System and method for inspecting wire bonding

A technology of leads and pins, which is applied in the field of inspection of lead welding systems, and can solve problems such as errors in inspection results, distinction between various components and leads, and image distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

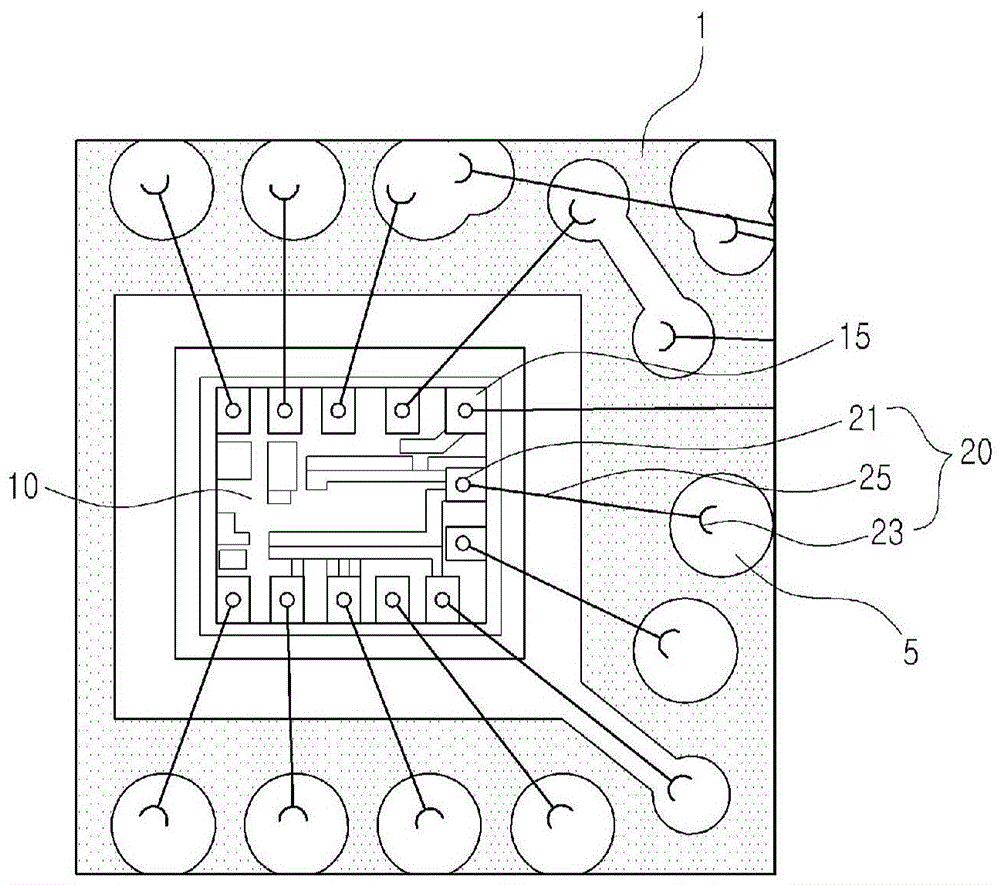

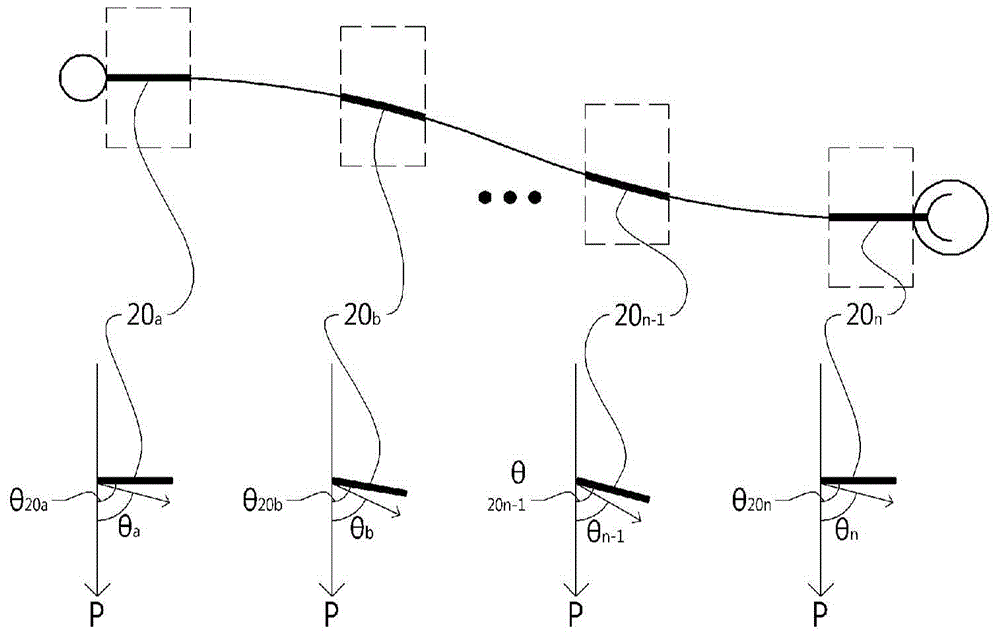

[0038] In the following, reference will be made to figure 2 Describes a method for checking such as figure 1 Shows whether the leads of the substrate on which the semiconductor chip is mounted are properly soldered or not.

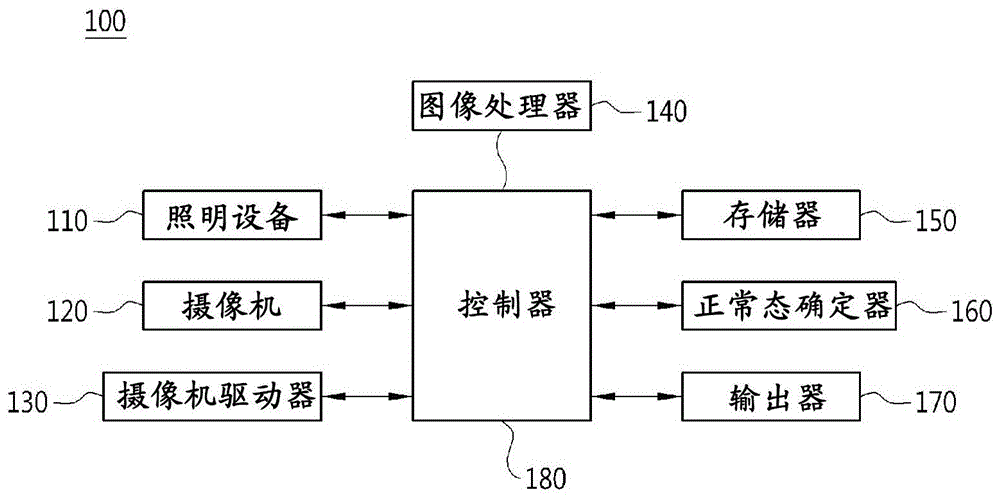

[0039] figure 2 is a block diagram illustrating the configuration of a wire bonding inspection system according to an exemplary embodiment of the present invention.

[0040] refer to figure 1 and figure 2 , the wire bonding inspection system 100 according to the present invention photographs the substrate 1 on which the chip 10 is bonded as a 2D image, and determines whether the wires 20 are normally connected. To achieve this, the wire bonding inspection system 100 may include an illumination device 110 , a camera 120 , a camera driver 130 , an image processor 140 , a memory 150 , a normal state determiner 160 , an outputter 170 and a controller 180 .

[0041] In order for the camera 120 to capture accurate images, the lighting device 110 emits li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com