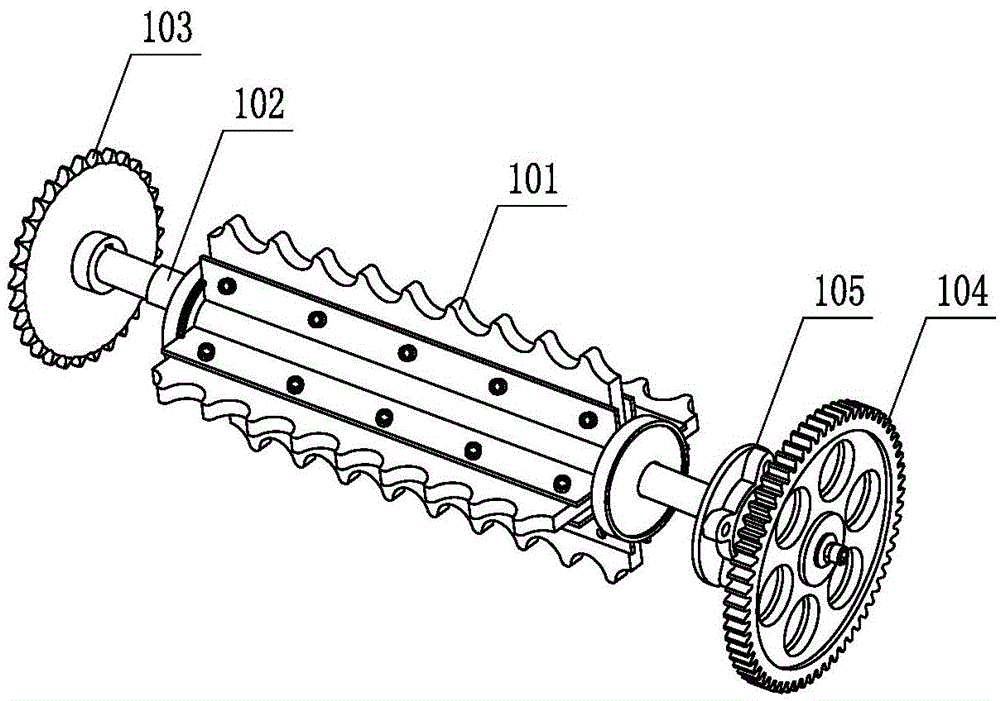

Leaf cleaning roller component for sugarcane combine

A combine harvester and leaf stripping technology, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve problems such as shortening the service life of parts, reducing production efficiency, and troublesome debugging processes, so as to prolong the service life and improve work efficiency. Efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

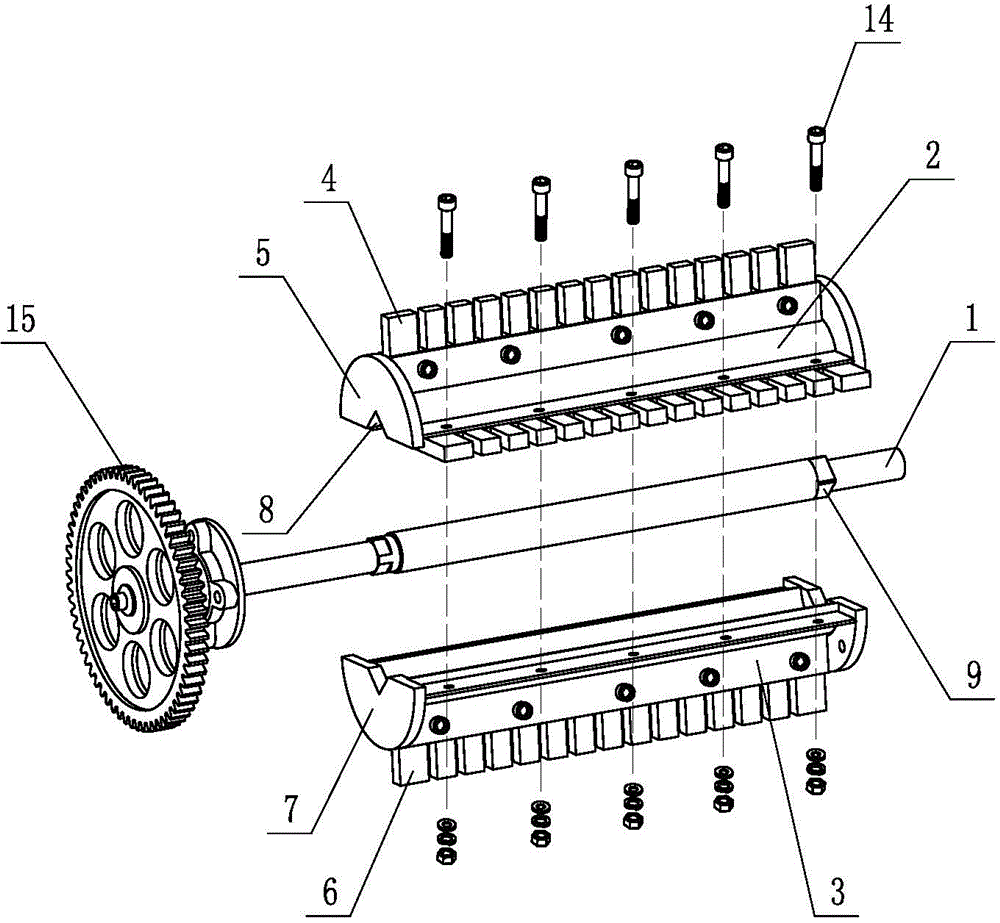

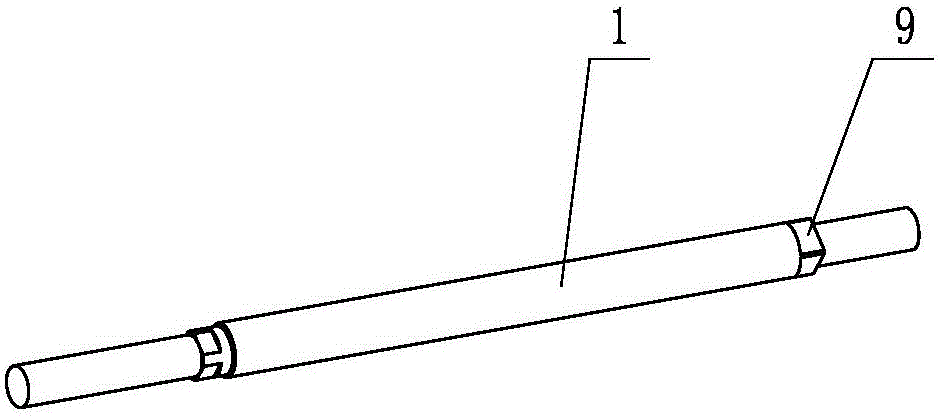

[0016] see figure 2 , a leaf stripping roller assembly of a sugarcane combine harvester, comprising a rotating shaft 1, a leaf stripping roller, on the outer circumferential surface of the leaf stripping roller, a plurality of rows of leaf stripping brush blades are fixed along its axial direction, and the leaf stripping roller uses the The rotating shaft is axisymmetrically divided into an upper half roller 2 and a lower half roller 3, and the upper half roller and the lower half roller are fixedly connected by bolts; the two ends of the upper half roller and the lower half roller are respectively provided with semicircular Shaped flanges 5 and 7, two semicircular flanges are combined to form a full circular flange; the semicircular flanges are respectively provided with V-shaped keyways 8 at their center positions, then A diamond-shaped keyway is formed in the center of the combined full-circle flange; positioning keys matching the rhombus-shaped keyway are provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com