A kind of involute rotor of internal mixer

An involute and internal mixer technology, applied in the field of involute rotors of internal mixers and internal mixer rotors, can solve the problems of low capacity, affecting the continuity of rubber materials, small mixing effect, etc. Good performance, great practical value, and a wide range of applications in industrial fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

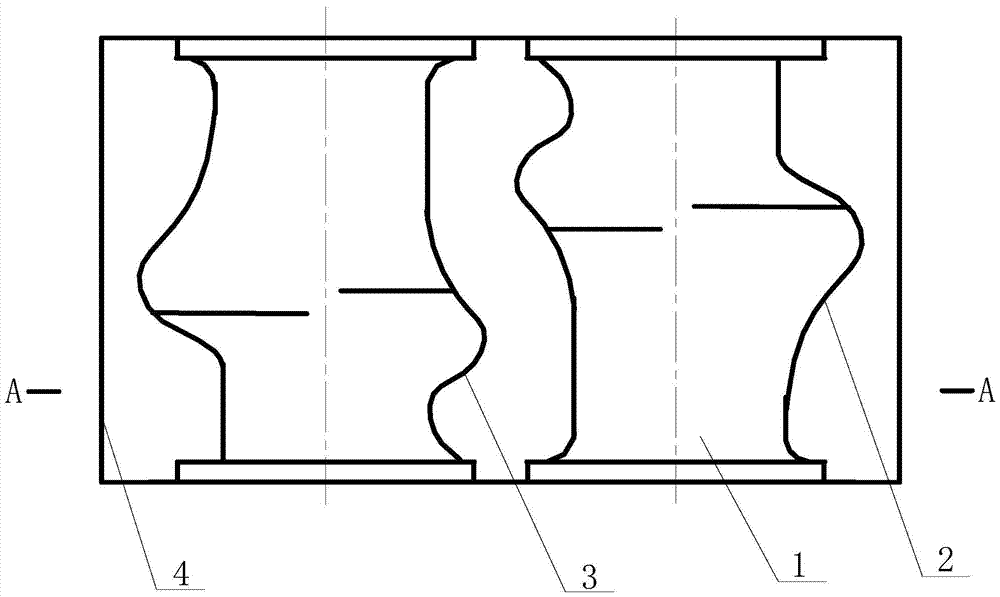

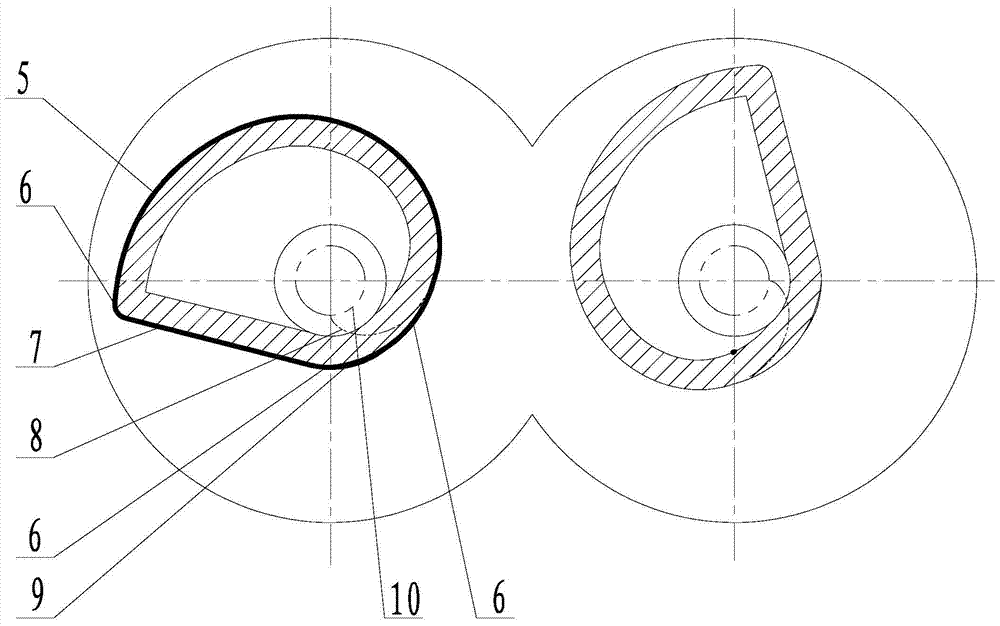

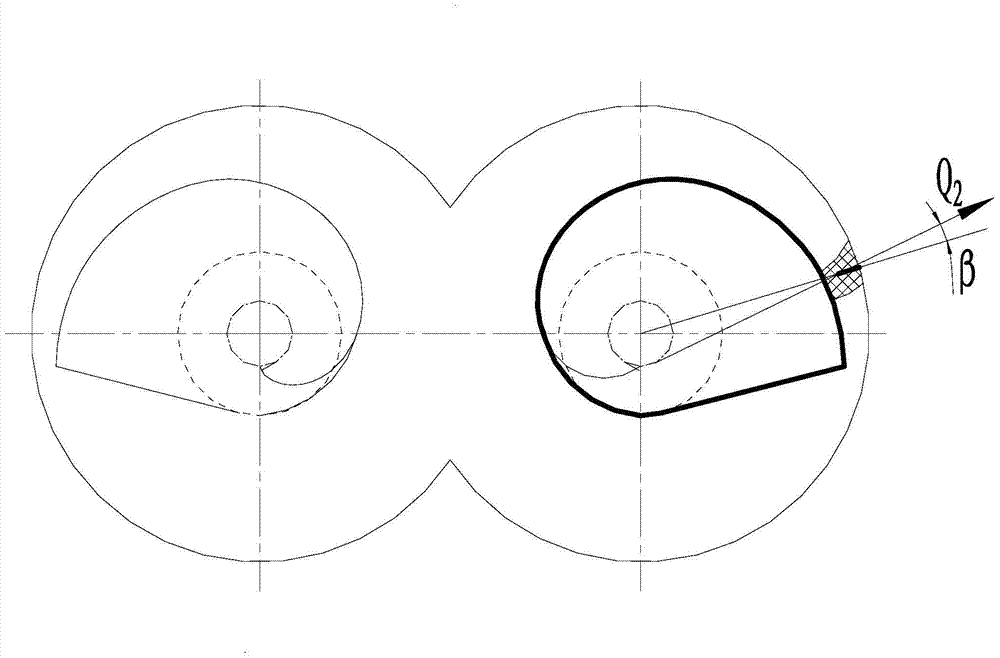

[0021] Such as figure 1 and figure 2 Shown: an involute rotor of an internal mixer, including a rotor base 1, the surface of the rotor base 1 is formed with a long spiral rib 2 and a short spiral rib 3 at one time, and the two rotors are placed side by side in the mixing chamber 4 of the internal mixer Inside, rotate in opposite directions when working. The outer contour of any cross-section of the rotor composed of the rotor base 1, the long helical rib 2 and the short helical rib 3 is composed of the arc of the rotor base circle 9, the involute rotor rib working surface 5, a straight line or The concave curved rotor non-working surface 7 and the arc transition line 6 are composed. The rotor base 1 and the long helical ribs 2 and short helical ribs 3 on its outer surface constitute an involute rotor. The involute base circle 10 is the occurrence circle of the involute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com