Implementation method of submerged water circulation cooling system for automobile brake drum

A drum immersion type and automobile brake technology, which is applied in the direction of cooling brakes, brake safety systems, vehicle components, etc., can solve the problems that cooling water cannot be sprayed to brake drums, shorten the service life of brake drums, and have no safety monitoring facilities. The best braking effect, eliminating potential safety hazards, and avoiding the effect of slippery road surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the content involved in the embodiments.

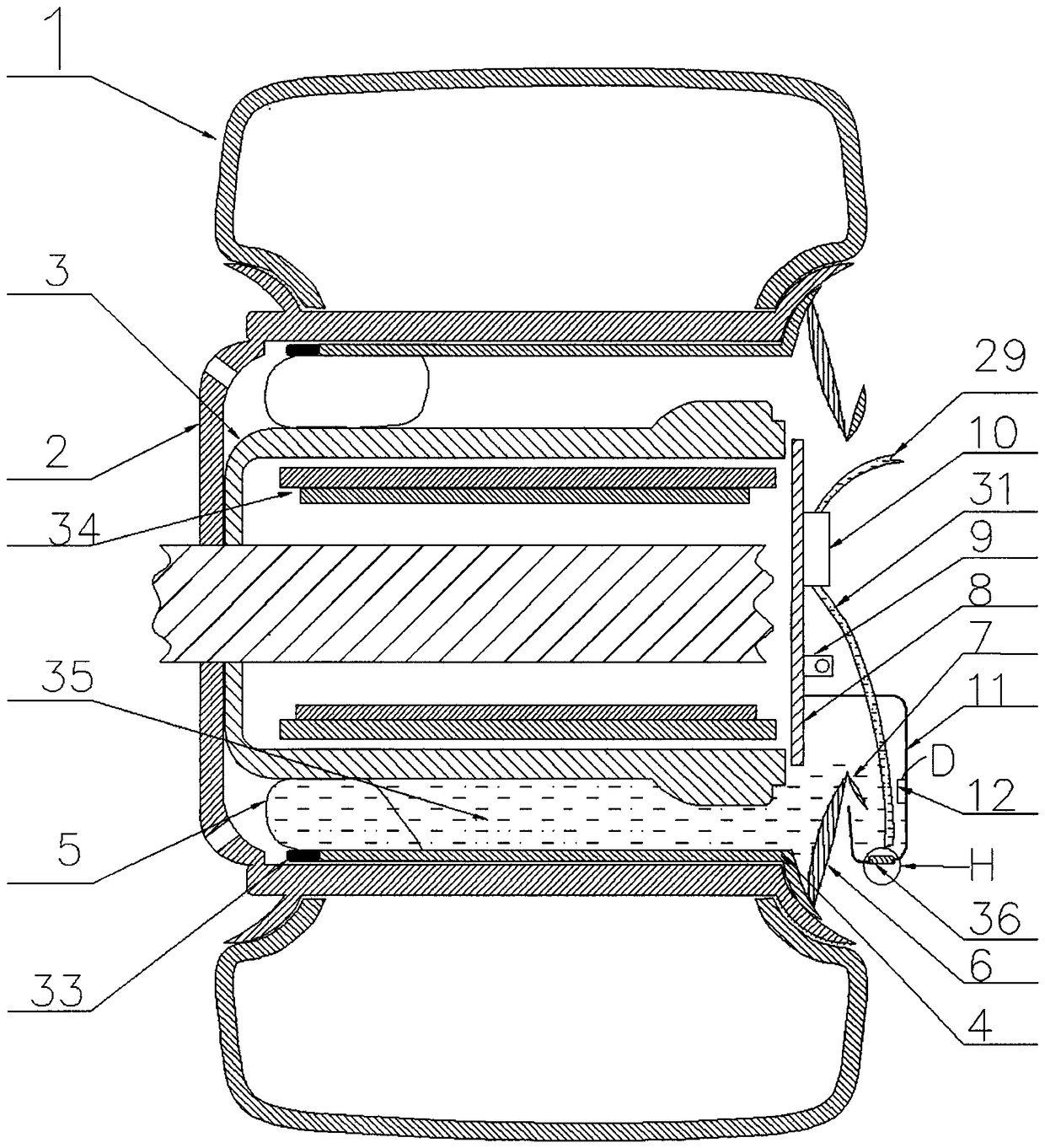

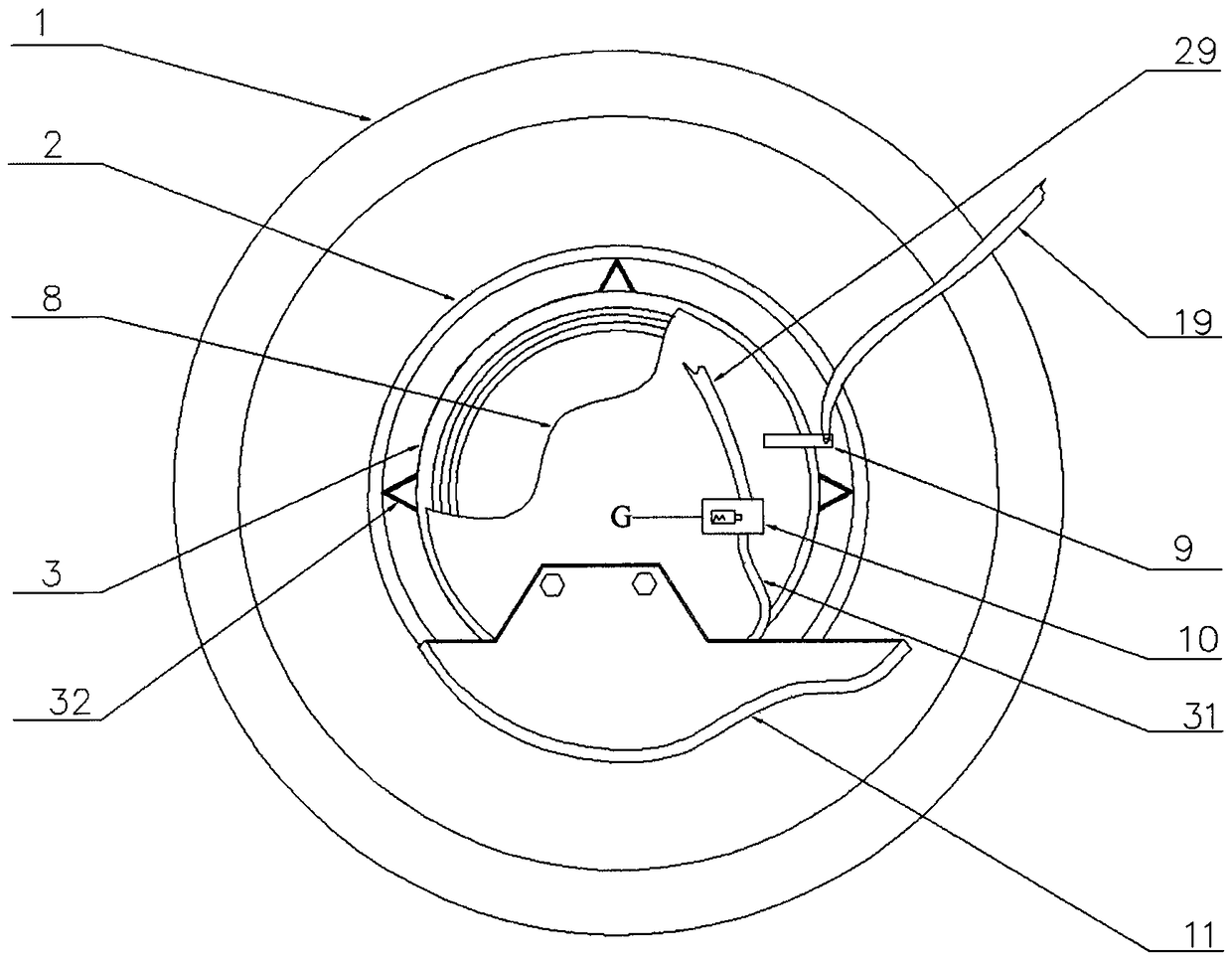

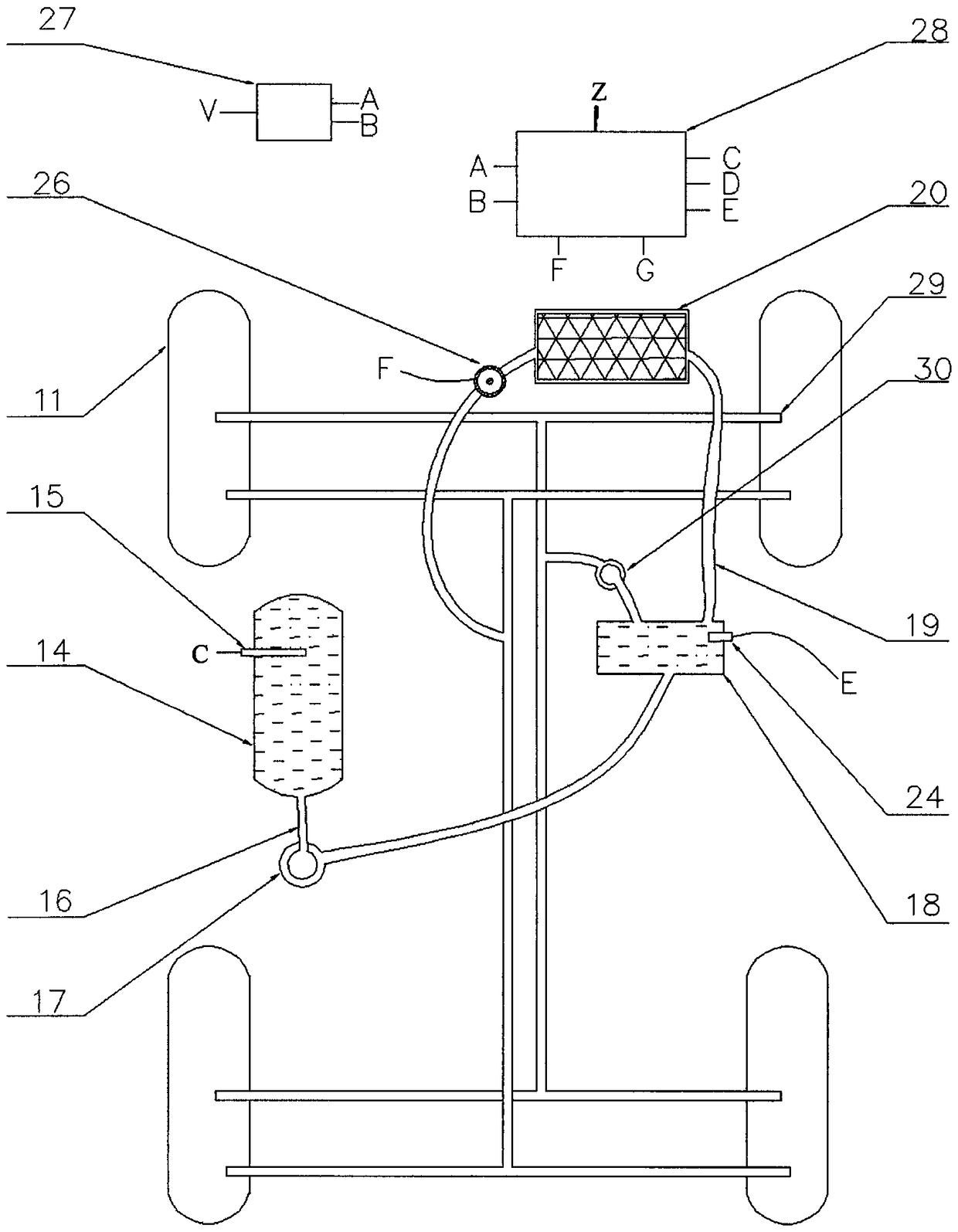

[0040] In the embodiment, the outer end of the cylindrical steel ring (4) is fixed on the inner diameter surface of the tire steel ring (2) with a V-shaped compression spring clamp (32) in the tire steel ring (2) of each axle of the automobile, The inner symmetrical circumference of the tire steel ring (4) is fixed on the inner diameter of the tire steel ring (2) with magnets (33) or C-shaped spring clips or other fastening methods, so as to achieve the purpose of optimizing the setting space and preventing damage. An annular water blocking plate (6) is arranged on the arc angle of the outer end of the cylindrical steel ring (4). ) shall not be higher than the inner diameter surface of the brake drum (3), an annular water diversion plate (7) is arranged on the annular water blocking pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com